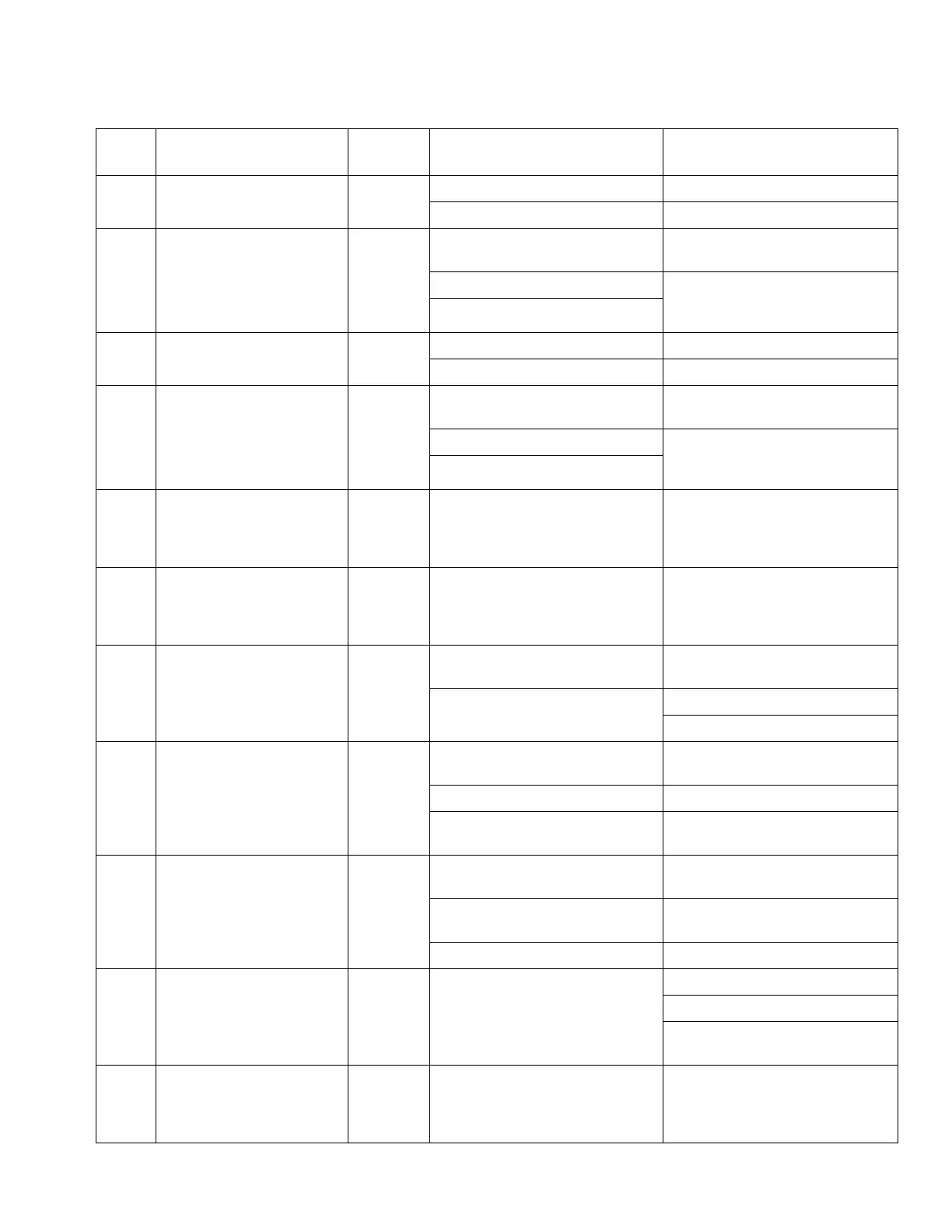

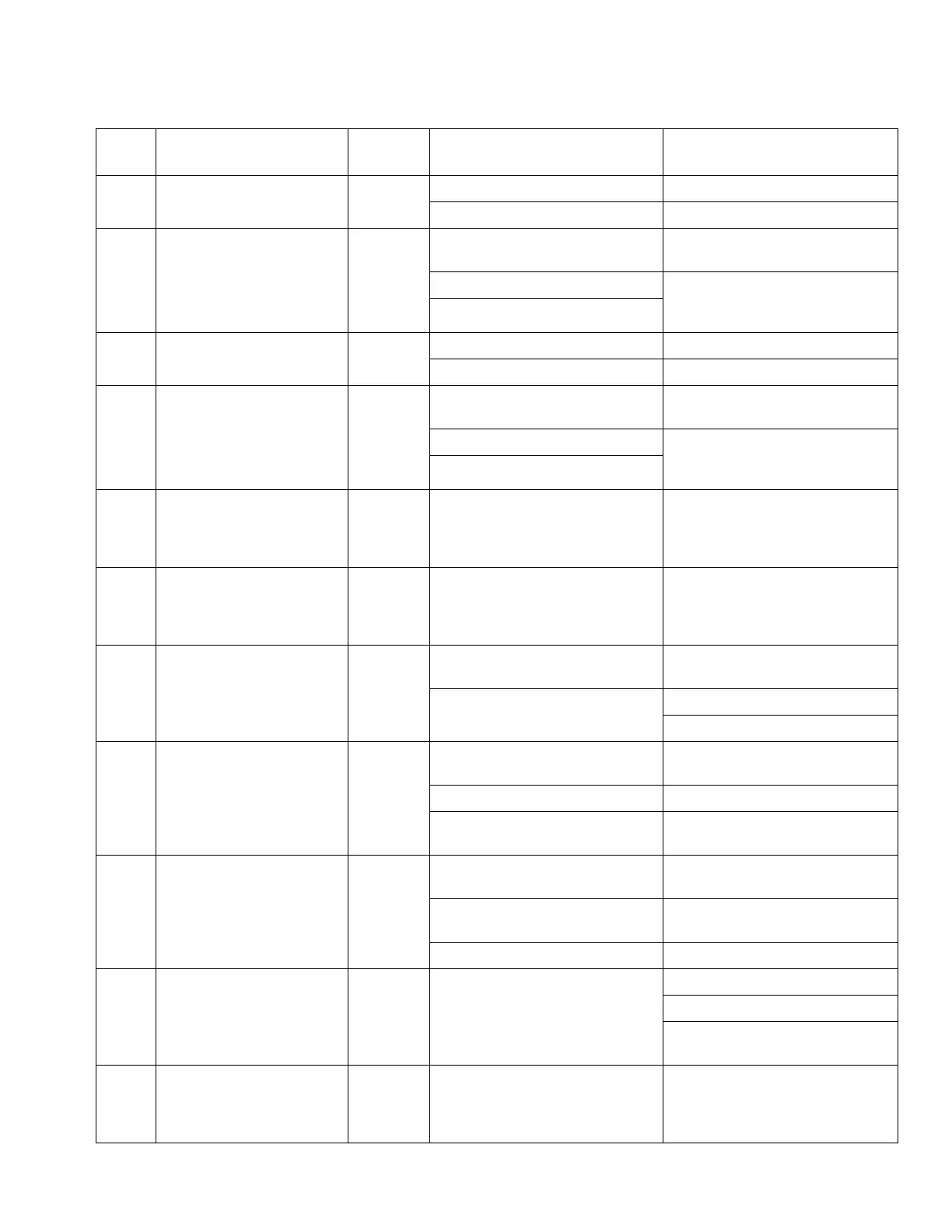

Appendix B - Alarms

3A2776K 91

F6AJ A Air Motor Linear Sensor

Jump Advisory.

Always System ran out of fluid. Add fluid to the system.

Linear sensor is bad. Replace linear sensor.

F6AK A Air Motor Reed Switch

Signal Missing Advisory.

Always Reed switch does not see the air

motor magnet.

Replace air motor reed switch

magnet.

Reed switches are bad. Replace air motor reed switch.

Prevent air motor icing. See

advisory P9AX and P9BX.

Air motor is icing.

F6BJ B Air Motor Linear Sensor

Jump Advisory.

Always System ran out of fluid. Add fluid to the system.

Linear sensor is bad. Replace linear sensor.

F6BK B Air Motor Reed Switch

Signal Missing Advisory.

Always Reed switch does not see the air

motor magnet.

Replace air motor reed switch

magnet.

Reed switches are bad. Replace air motor reed switch.

Prevent air motor icing. See

advisory P9AX and P9BX.

Air motor is icing.

F7AX

F7BX

System Detects Unexpected

Pump Movement (Fluid

Flow).

Spray Recirculation valve or dosing valve

open or leaking for more than five

seconds.

Close or repair recirculation valve,

and run Pump Test. See Pump and

Metering Test and Calibration for

Ratio by Weight Mode, page 48.

F8RX No movement occurred in

circulation mode

Circulation Pump did not move for 5 seconds

while in circulation. User may have

attempted to spray in circulation

mode.

Use spray mode for spraying.

L2F1

L2F2

Tank Level Low Advisory Spray and

Tank

Tank level less than 10% below

tank empty setpoint for 3 seconds.

Add material to tank.

Air solenoid is bad. Replace air solenoid.

Increase air pressure to solenoid.

L3F1

L3F2

Tank Level High Advisory Spray and

Tank

Tank level greater than 10% above

tank full setpoint for 3 seconds.

Lower the tank level.

Air solenoid to feed pump is bad. Replace air solenoid.

Fluid expanded when air pressure

was removed.

Increase air pressure to solenoid.

L4F1

L4F2

Tank Level High Alarm Always Tank level greater than 90% of

total tank volume for 3 seconds.

Lower the tank level.

Fluid expanded when air pressure

was relieved.

Lower the tank full setpoint.

Sensor rod is damaged. Replace sensor rod.

L6FC

L6FD

Tank Level Sensor Failure

Alarm

Always Cable is disconnected or bad Replace level sensor

Turn all sensor DIP switches to off

Connect level sensor cable to

system

*MAA

X

*MAB

X

Maintain Pump. Always, if

enabled

Pump usage exceeds user-set

limit. Maintenance due.

Service pump. See pump manual

listed on page 4.

Alarm

Code Alarm Problem

When

Active Cause Solution

Loading...

Loading...