Page 32 Section 9: Flue System and Air Supply

9.3 CONVENTIONAL FLUE SYSTEMS

! NOTE !

Under no circumstances can Grant Vortex boilers be

installed with existing ue systems. Only ue systems and

components suitable for wet ues should be used.

Failure to install the correct type of ue system will

invalidate the guarantee.

Grant condensing boilers have high operating eciencies and

low ue gas temperatures. Care must be taken to ensure the

ue system is suitable for the very low ue gas temperatures and

condensate in the ue gases.

Suitable conventional ue systems are available from Grant UK.

The ue must terminate in a down draught free area, i.e. at least

600 mm above the point of exit through the roof or preferably

above the ridge level.

The condensate may be allowed to run back into the boiler. A

condensate drain at the base of the ue system is not required.

The high level ue terminal must be at least 600 mm from

any opening into the building, and 600 mm above any vertical

structure or wall less than a horizontal distance of 750 mm from

the terminal.

More detailed information on the siting of the ue terminal can be

found in Figure 9-5 and Table 9-3.

The internal ue and liner diameter for all models up to 46kW

output must be 100 mm (4 in) and for the 46/58 and 58/70 models

125mm (5 in).

Twin wall ues are recommended for externally run ues to

reduce the possibility of the condensate freezing in the ue.

No part of any ue system should be made of an asbestos

material; aluminium must not be used in any part of the ue. Only

stainless steel ue components should be used.

If the draught conditions are satisfactory, the ue should terminate

with a standard cowl.

Refer to the locally applicable Building Regulations, BS 5410-1

and OFTEC Installation Requirements (OFTEC Books 2 and 3)

for further guidance on conventional ue systems.

! CAUTION !

It is important to ensure that the ue system is sealed and

that condensate cannot escape. Up to 1.5 l/h of condensate

can be produced in a conventional ue system.

Do not use re cement. The use of high temperature

silicone sealants is recommended.

! NOTE !

To comply with the requirements of the Building

Regulations Approved Document J - conventional ue

systems must have a ue data plate.

9.4 EXTERNAL VERTICAL CONVENTIONAL

FLUE (GREEN SYSTEM)

The external system can terminate at either high level or vertically

(above roof level) as required. The vertical or high level terminal

must terminate in accordance with BS 5410-1. The minimum

dimensions for locating the high level terminal from building

features (windows, doors, etc.) are shown in Figure 9-5 and Table

9-3.

The Green system comprises of ve insulated extension lengths,

45° elbows, a vertical terminal and a high level horizontal terminal.

Locking bands are provided with all vertical extensions and

terminals. Ensure that the locking bands are tted.

Two types of wall bracket are also available (standard and

adjustable) to support the vertical ue components.

The maximum vertical height (from the top of the boiler to the

terminal) for the ‘Green’ system twin wall ue is 19 metres. Only

two 45° elbows may be used in the complete system.

If the ue terminal is tted less than 2 metres above a surface to

which people have access, the terminal must be protected by a

guard. The guard must be manufactured from stainless steel and

should be tted centrally over the ue terminal and securely xed

to the wall.

CONNECTION OF VERTICAL GREEN FLUE

SYSTEM

1. Connect Grant Green system to the boiler ue outlet using

the Grant Green system External Module starter elbow

(product code: GKM90 for models up to 26kW or GKM200 for

models ranging from 26-70kW).

2. Fit the starter elbow into the boiler connector after rst

ensuring that the seal is in place in the connector.

! NOTE !

Lubricate the seal on the boiler connector using the

lubricant provided before attempting to t the starter piece.

Ensure that seals in all ue sections are lubricated before

installing.

3. Assemble the remainder of the ue system as required,

lubricating the seal on each component before tting and

securing every joint with the locking band provided.

The external vertical ue (Green system) components available

from Grant UK can be found in Figure 9-3 and Table 9-2.

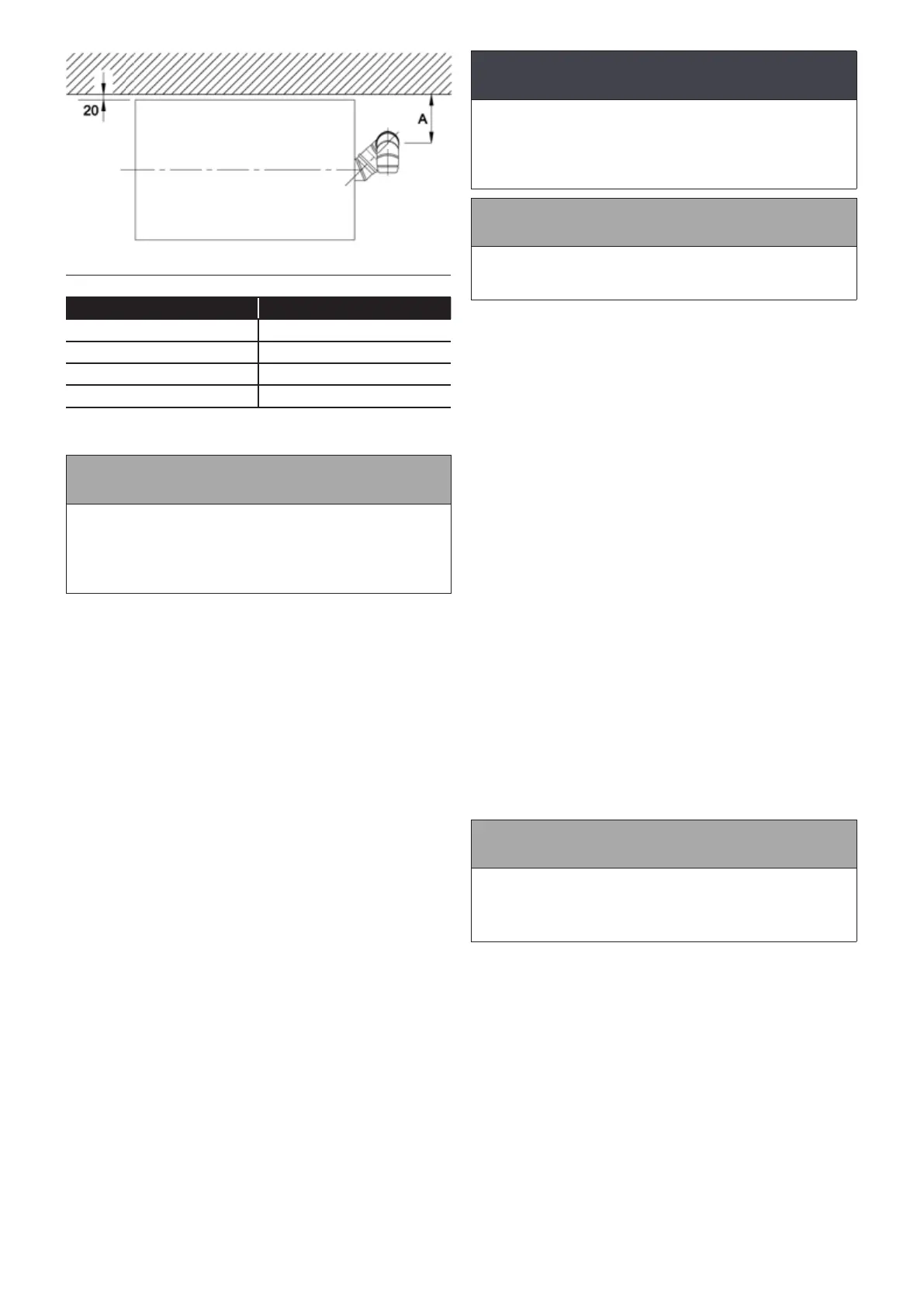

Table 9-1: Distance of plume diverter centre from external wall

Model Dimension A (mm)

15/21 115

15/26 177

26/36 & 36/46 150

46/58 & 58/70 188

Figure 9-2: Plume diverter kit - Plan View

Loading...

Loading...