Page 65

Appendix A2: Wilo-PARA 25-130/7-50/SC-6#GRA

APPENDIX A2 WILO-PARA 25-130/7-50/SC-6#GRA

CIRCULATING PUMP

A2.1 WILO-PARA 25-130/7-50/SC-6#GRA

CIRCULATING PUMP

A2.1.1 PUMP SPECIFICATION

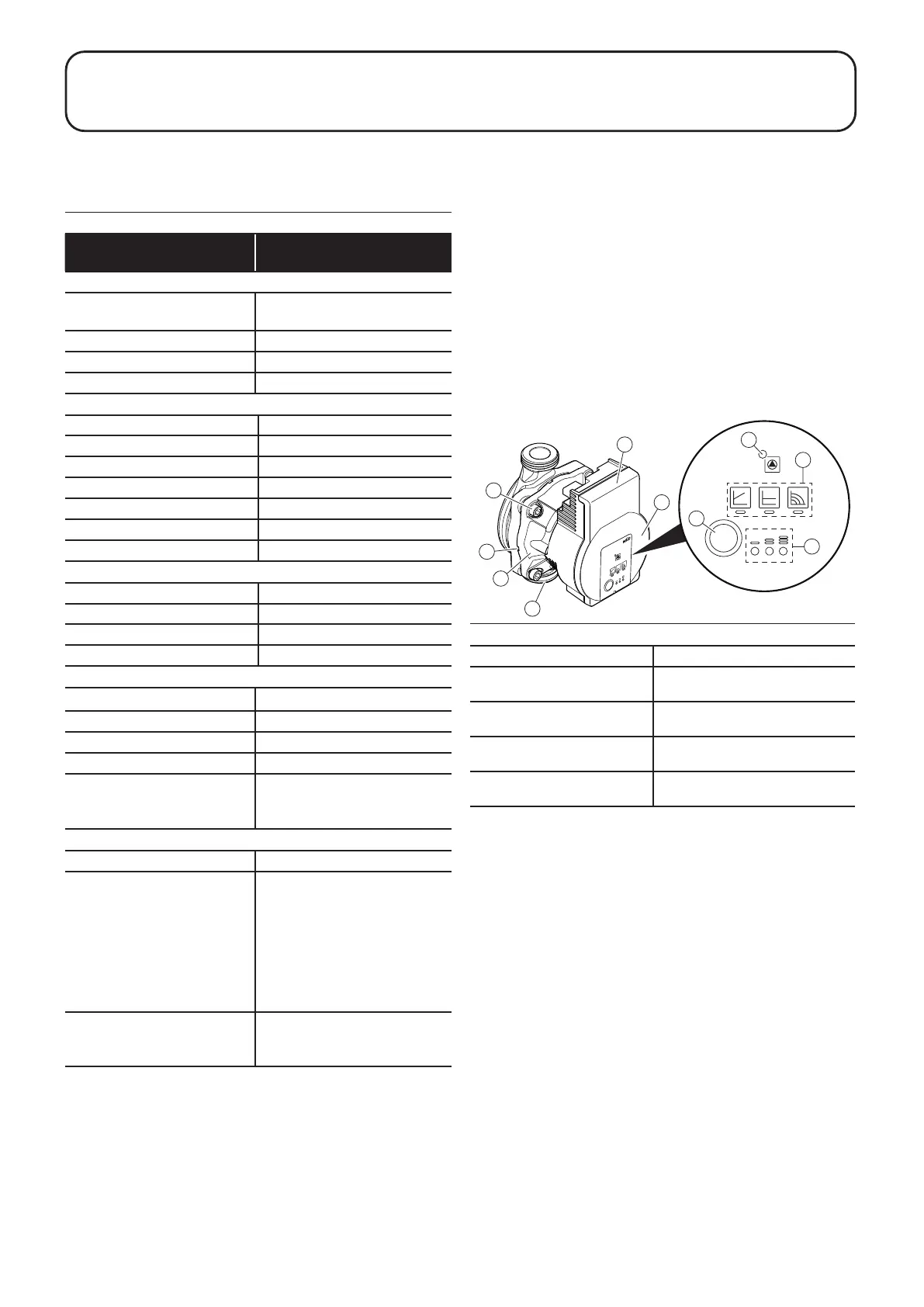

Table A2-1: Pump specication

Make and model

Wilo - PARA 25-130/7- 50/SC-

6#GRA

Construction

Pump housing

Cast iron (with cataphoresis

treatment)

Impellar PP composite with GF 40%

Pump shaft Stainless Steel

Bearing Carbon, metal impregnated

Motor Data

Speed 2580 - 4700rpm

Power consumption @ 1 - 230V 8.2 - 50W

Current @ 1 - 230V 0.07 - 0.43A

Minimum starting voltage 170V

Minimum running voltage 160V

Peak inrush current >3A

Starting torque >25N.cm

Electrical

Mains connection 1ph 230V AC +10%/-15% 50/60Hz

Protection Class IPx4D

Insulation Class F

Motor Protection Integrated

Performance

Max. delivery head 7.7m @ Q = 0 m

3

/h

Max. volume ow 3.5 m

3

/h

Minimum suction head @ 50/95°C 0.5/4.5m

Energy Eciency Index (EEI) ≤ 0.20

Settings

∆P-variable (1-7m head)

∆P-constant (1-7m head)

Constant Speed (I, II and III)

Application

Maximum Static Pressure PN10

Fluid Temperature range @

maximum ambient temperatures

(See Section A2.1.2)

Maximum ambient temperature

58°C: 0 to 100°C

Maximum ambient temperature

62°C: 0 to 90°C

Maximum ambient temperature

66°C: 0 to 80°C

Maximum ambient temperature

71°C: 0 to 70°C

Approved Fluids

Heating Water

Water/Glycol - Max 1:1 (above 20%

check pumping data)

1

2

3

4

5

8

9

10

7

6

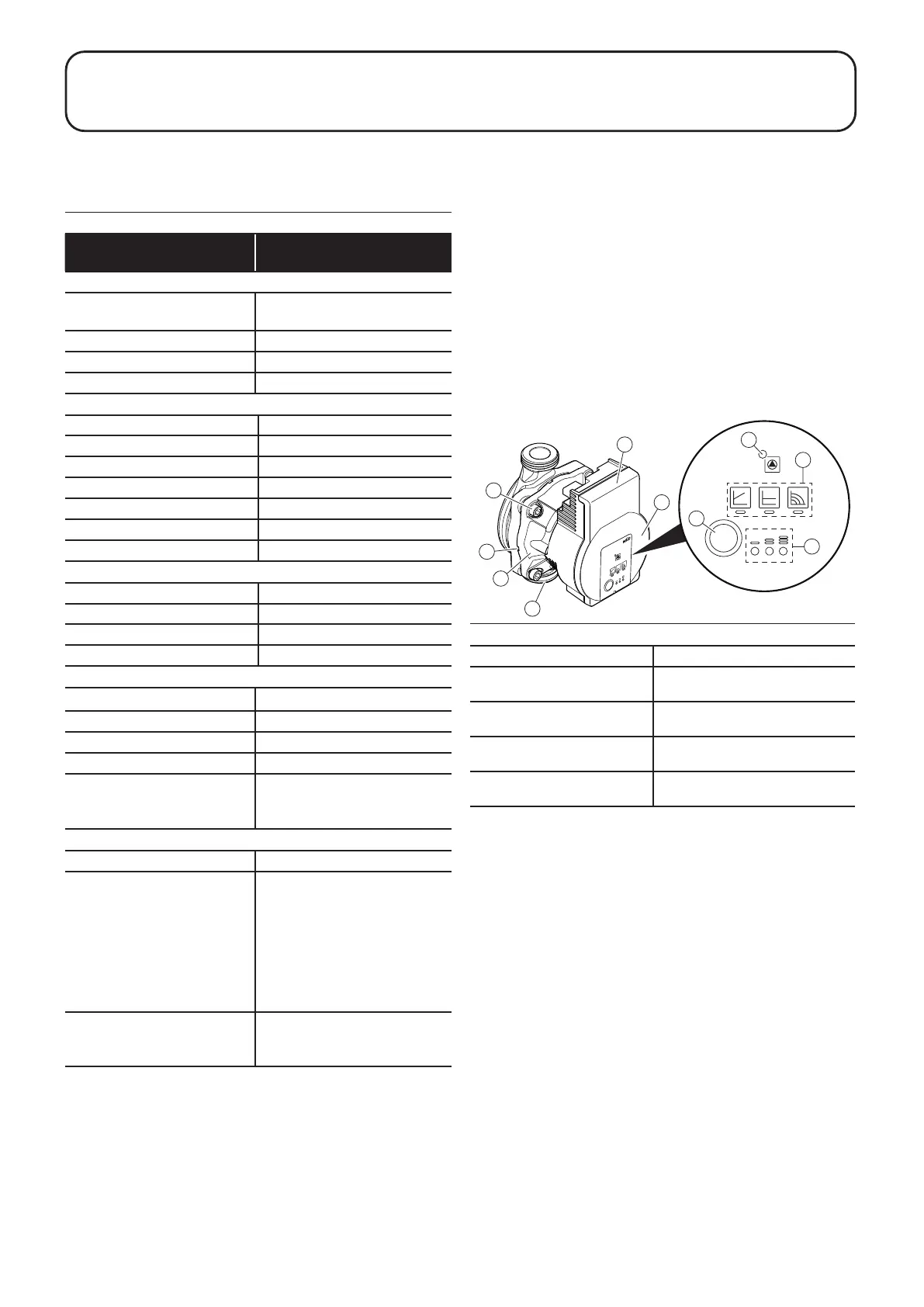

Figure A2-1: Pump components and control panel

1. Pump housing 6. Rating plate

2. Glandless motor 7. Operating button for pump

adjustment

3. Condensate drain openings

(4 around motor)

8. Run/Fault signal LED

4. Housing screws 9. Display of selected control

mode

5. Control module 10. Display of selected pump

curve (I, II, III)

A2.1.3 PUMP COMPONENTS

A2.1.4 CONTROL PANEL

Indicator LEDs

• Run/Fault signal LED (item 8, Figure A2-1)

- LED is GREEN when pump is running in normal pump

operation.

- LED lights up red/ashes when there is a fault (refer to

Section A2.2).

• Control mode display LEDs (item 9, Figure A2-1)

• Pump curve display LEDs (item 10, Figure A2-1)

• LED combinations are used to indicate when the following

functions are in operation:

- Pump venting (refer to Sections A2.1.5 and A2.1.6 for

information on how to activate this function).

- Manual restart (refer to Sections A2.1.5 and A2.2 for

information on how to activate this function).

- Key lock (refer to Sections A2.1.5 and A2.1.6 for

information on how to activate this function).

A2.1.2 THERMAL PROTECTION FUNCTION

The pump is equipped with a thermal self-protection mode.

If the uid temperature exceeds the maximum value at a specic

ambient temperature, e.g. 90°C at an ambient of 62°C, the pump

will automatically reduce the power consumption, reducing the

speed and performance of the pump.

In this condition the Run/Fault signal LED will be blinking RED.

When normal temperature conditions return the pump will

automatically revert to normal operation.

If the uid temperature increases further, the thermal protection

function may stop the pump temporarily.

In this condition the Run/Fault signal LED on the pump will be

constant RED until normal temperature conditions return.

Loading...

Loading...