Page 49

12 FAULT FINDING

Section 12: Fault Finding

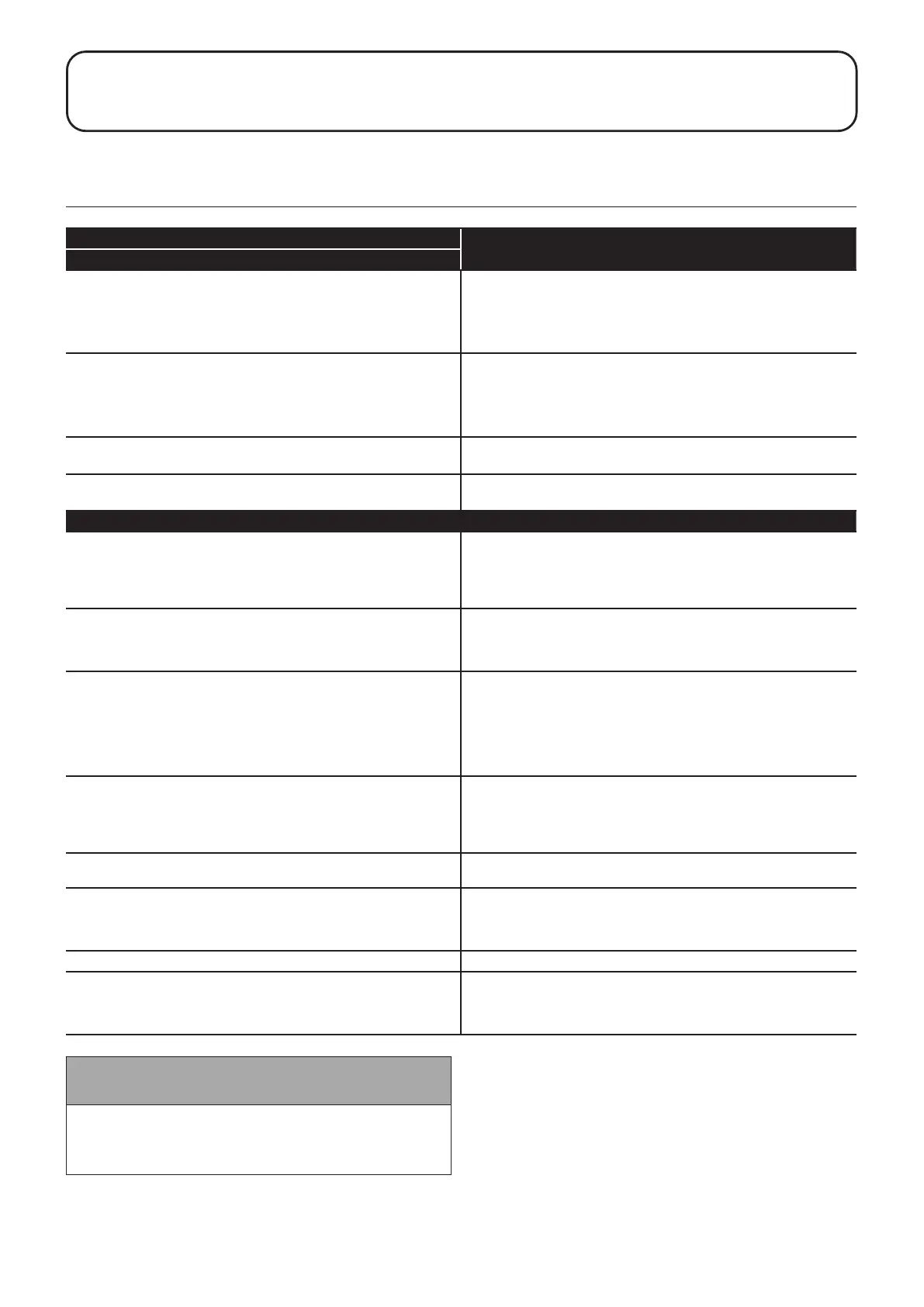

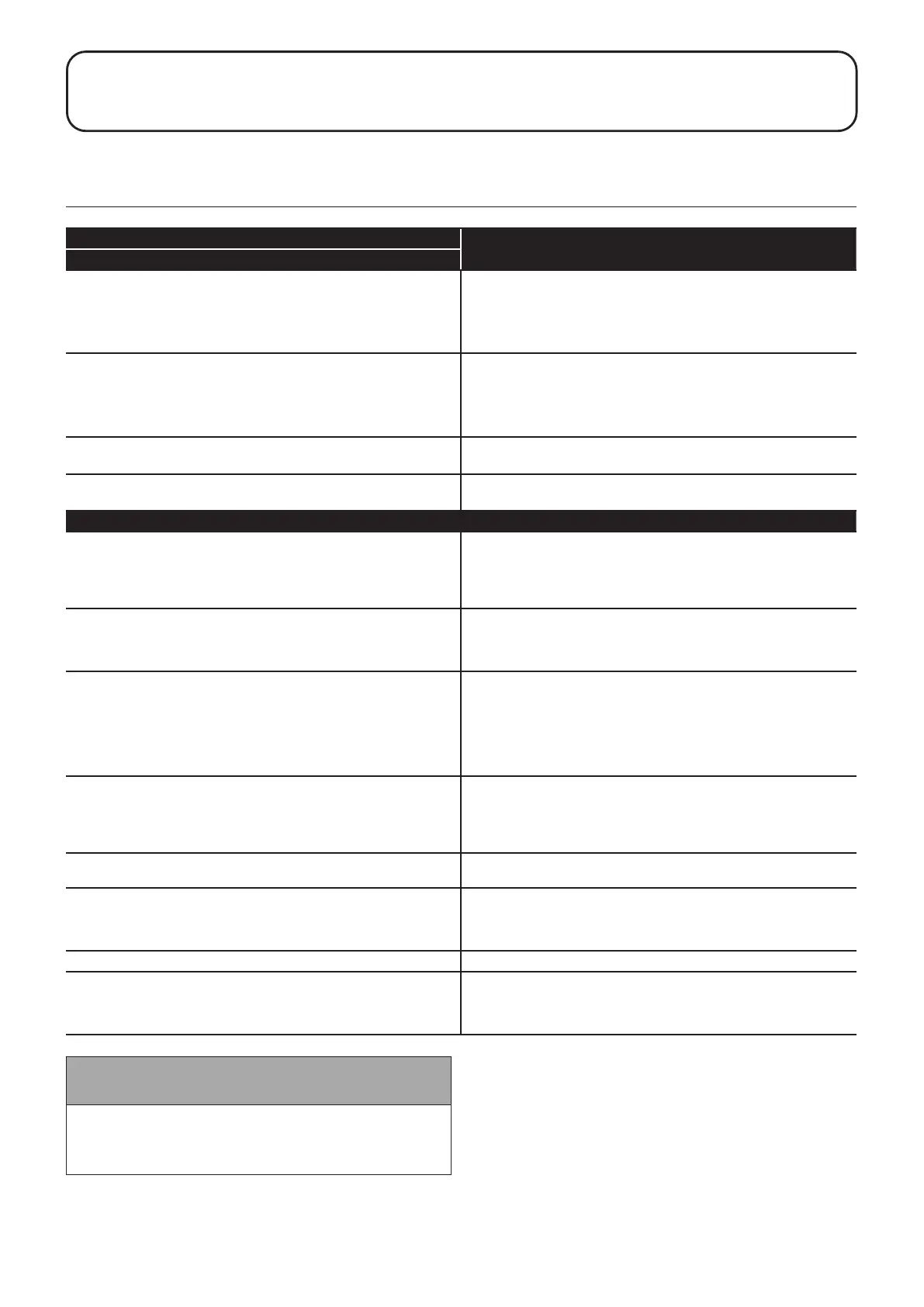

12.1 BOILER FAULT FINDING

Always isolate the electricity supply to the boiler before working on the boiler.

Figure 12-1: Boiler fault nding

Fault

Remedies

Boiler will not start:

No fuel supply.

Ensure that an adequate supply of fuel is available and that the fuel

supply valve is open.

Check the condition of the fuel lter, clean if necessary.

Ensure fuel supply is reaching burner and vent pump.

Check that the re valve has not operated to shut o the oil supply.

No electricity supply.

Ensure electricity supply to the boiler is switched on and that all controls

are calling for heat.

Ensure that the overheat thermostat has not tripped, reset if necessary.

Check that a mains supply is present at the burner terminal block.

If not, check the boiler and overheat thermostat.

Burner not starting - fuel and electricity supplies present.

Press the reset button on the burner control box if it is lit.

Refer to burner fault nding charts.

Burner lights but goes to lock-out.

If the ame is unstable, check the combustion settings.

Refer to burner fault nding charts.

Boiler works but:

1. Visible smoke from ue or high smoke number.

Insucient air supply - check the air damper setting and the condition of

the fan.

Check room ventilation is adequate, see Section 9.1.

Check the nozzle size and type.

Fuel pressure may be too high - check and adjust.

2. Burner pulses.

Insucient air supply - check the air damper setting and the condition of

the fan.

Check room ventilation is adequate, see Section 9.1.

Check the nozzle size and type.

3. Flame slow to stabilise during start up.

Insucient air supply - check the air damper setting and the condition of

the fan.

Check room ventilation is adequate, see Section 9.1.

Check the nozzle size and type.

Fuel pressure may be too low - check and adjust.

Insucient draught - clean boiler heat exchanger and check condition of

ue.

4. Water temperature low.

Undersized nozzle and/or low fuel pressure.

Check condition of boiler heat exchanger and clean if necessary.

Check the boiler thermostat.

Check the combustion settings.

Check the condition of the fuel lter.

5. Boiler operating on overheat thermostat.

Faulty boiler thermostat. No circulation, check circulating pump. Check for

air lock.

6. Fumes and pung during starting (conventional ue)

Check the condition of the chimney, ensure it is not blocked and is high

enough to produce the required draught. Check that there is an adequate

air supply near the burner and that a kitchen fan is not drawing products

out of the burner.

7. Oil odours. Check all fuel line connections, remake as necessary.

8. Combustion fumes smell.

Check boiler cleaning cover and seal are correctly tted.

Check burner is correctly tted onto ange.

Check ue is correctly sealed into ue outlet of boiler.

Check the condensate pipe and trap are operating correctly.

! NOTE !

For an overview of the fault diagnostic capabilities built

into the circulating pumps that come supplied with sealed

system kits, please refer to Appendix A1 or A2, as required,

at the back of this installation and servicing manual.

Loading...

Loading...