Page 40

Section 10: Commissioning

10.3 BURNER SETTINGS:

RDB3.2 BURNERS

FOR 46/58 AND 58/70 MODELS

With the burner removed from the boiler:

2

5

4

7

6

1

3

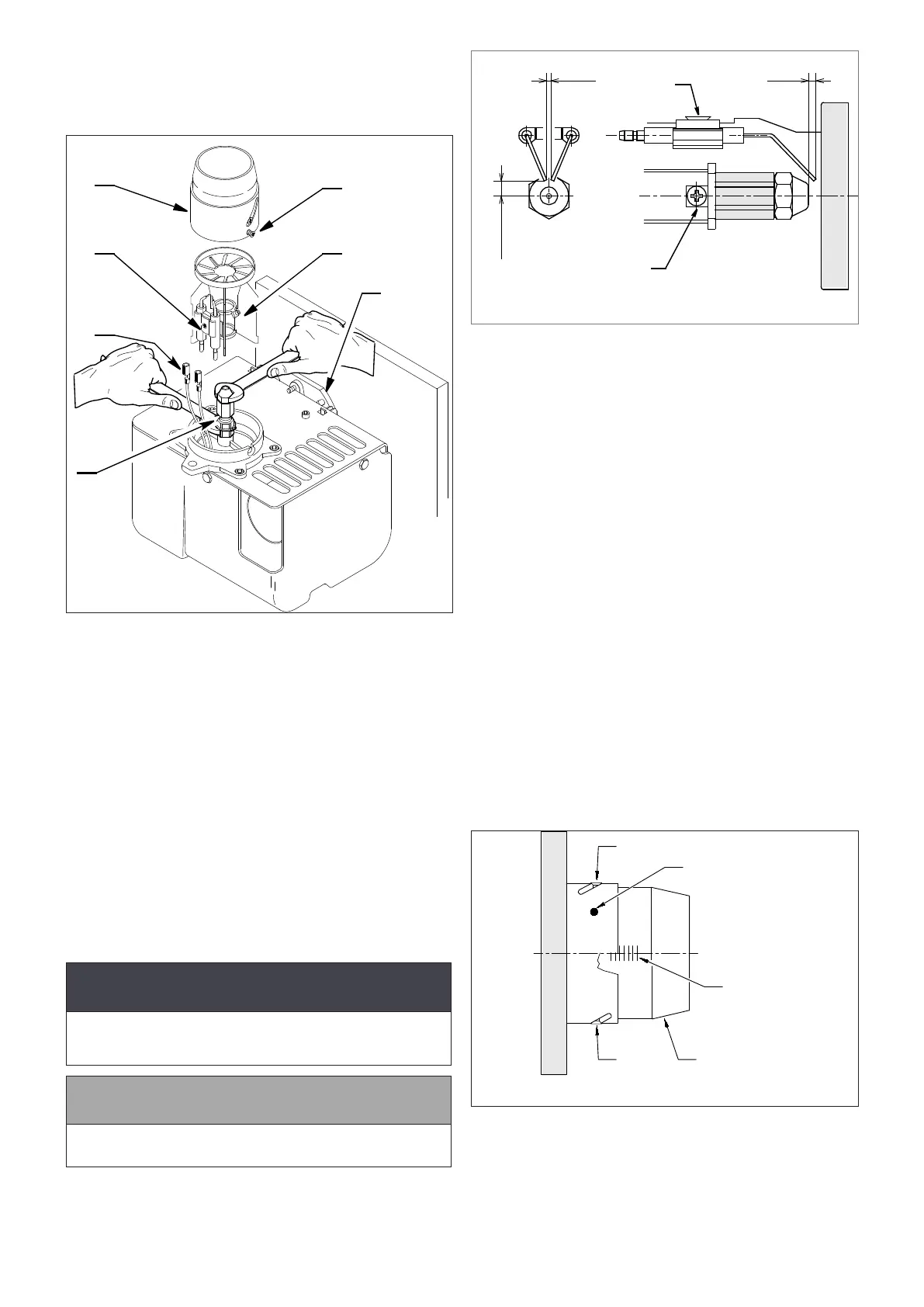

Figure 10-5: Riello RDB 3.2 burner head, diuser and nozzle

holder

1. Unscrew and remove the two screws holding the air intake

spigot to the top of the air inlet cover.

2. Remove and discard the air intake spigot and gasket.

3. Fit the slotted air intake (provided loose with the boiler) to the

top of the air intake cover and secure using one of the two

screws previously removed.

4. Remove the burner head. Refer to Figure 10-5. Loosen both

xing screws (3) and remove head from burner (2).

5. Check the nozzle is correct for the required boiler output.

Refer to Table 2-3 for the correct nozzle size and type for the

required boiler output.

6. If the nozzle needs to be replaced - Remove the diuser/

electrode assembly. Refer to Figure 10-5.

• Loosen the diuser clamp screw (7) and remove the

diuser/electrode assembly from the nozzle holder (6).

• Disconnect both ignition leads (4) from the electrodes.

7. Use a 16mm spanner to remove/re-t the nozzle, whilst

holding the nozzle holder using a 17mm spanner.

! CAUTION !

The use of an ill-tting spanner will damage the nozzle

and could lead to an incorrect ame pattern and poor

combustion.

! NOTE !

Ensure that the nozzle is securely tightened so that it does

not leak but DO NOT OVER TIGHTEN!

8. Reconnect ignition leads to electrodes.

9. Re-t the diuser/electrode assembly to the nozzle holder.

10. Refer to gure 10-5. Slide diuser (5) along the nozzle holder

(6) until hard against the stop and tighten diuser clamp

screw (7).

1

2

4mm

+

0

3mm

0

-

5.75mm

0.2

0.5

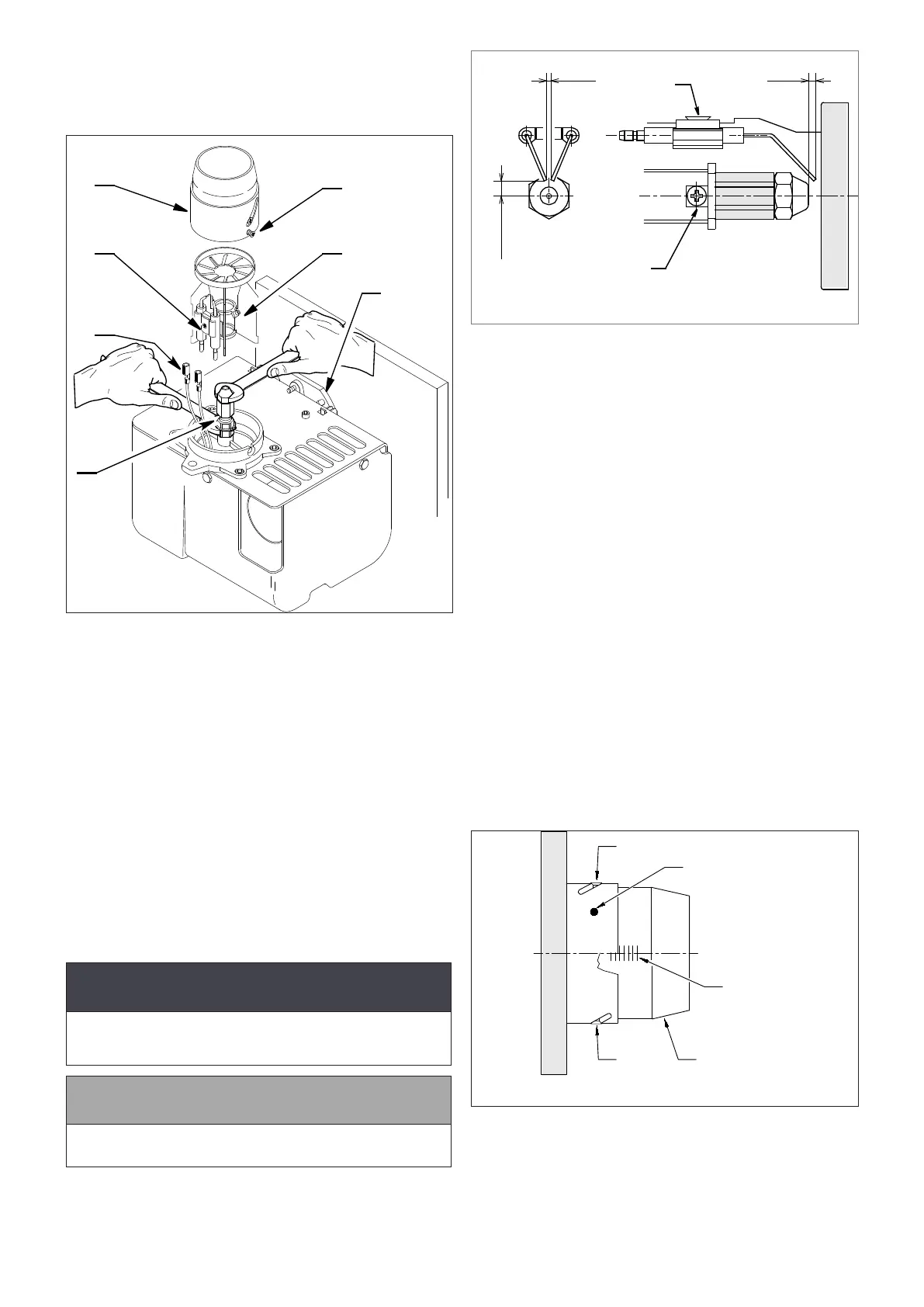

Figure 10-6: Ignition electrode settings

11. Check/adjust the electrode assembly to give the correct gap

(4mm) between the nozzle and electrodes. Refer to Figure

10-6.

• To adjust the electrode position:

- Loosen the electrode clamp screw.

- Slide the electrode assembly to give the correct gap

of 4mm.

- Tighten the electrode clamp screw.

12. Re-t the burner head. Refer to Figure 10-5.

• Locate the head xing screws in the countersunk slots in

the burner collar.

• Tighten the two screws (3) to secure the head (2) in

position on the burner.

13. Check the combustion head setting.

• The correct head setting depends on the required output

of the boiler. Refer to Table 2-3

• This should be set to ‘0’ in all cases except when the

58/70 is set to maximum (70kw) output.

• In this case the head is set to ‘4’ (i.e. on the 4th line).

Refer to Figure 10-7.

14. To adjust the head setting (if required):

• Loosen the two screws in the curved slots in outer ring

of the head (NOT the two head xing screws). Refer to

Figure 10-7.

• Rotate the end of the burner head until either ‘0’ or the

4th line, as required.

• Tighten the two screws to x the head in the required

position.

0

Shutter

Blast tube

Screw

Slotted ring

Screw

Figure 10-7: Riello RDB 3.2 Combustion Head Setting

Loading...

Loading...