Section 2: Technical Data Page 7

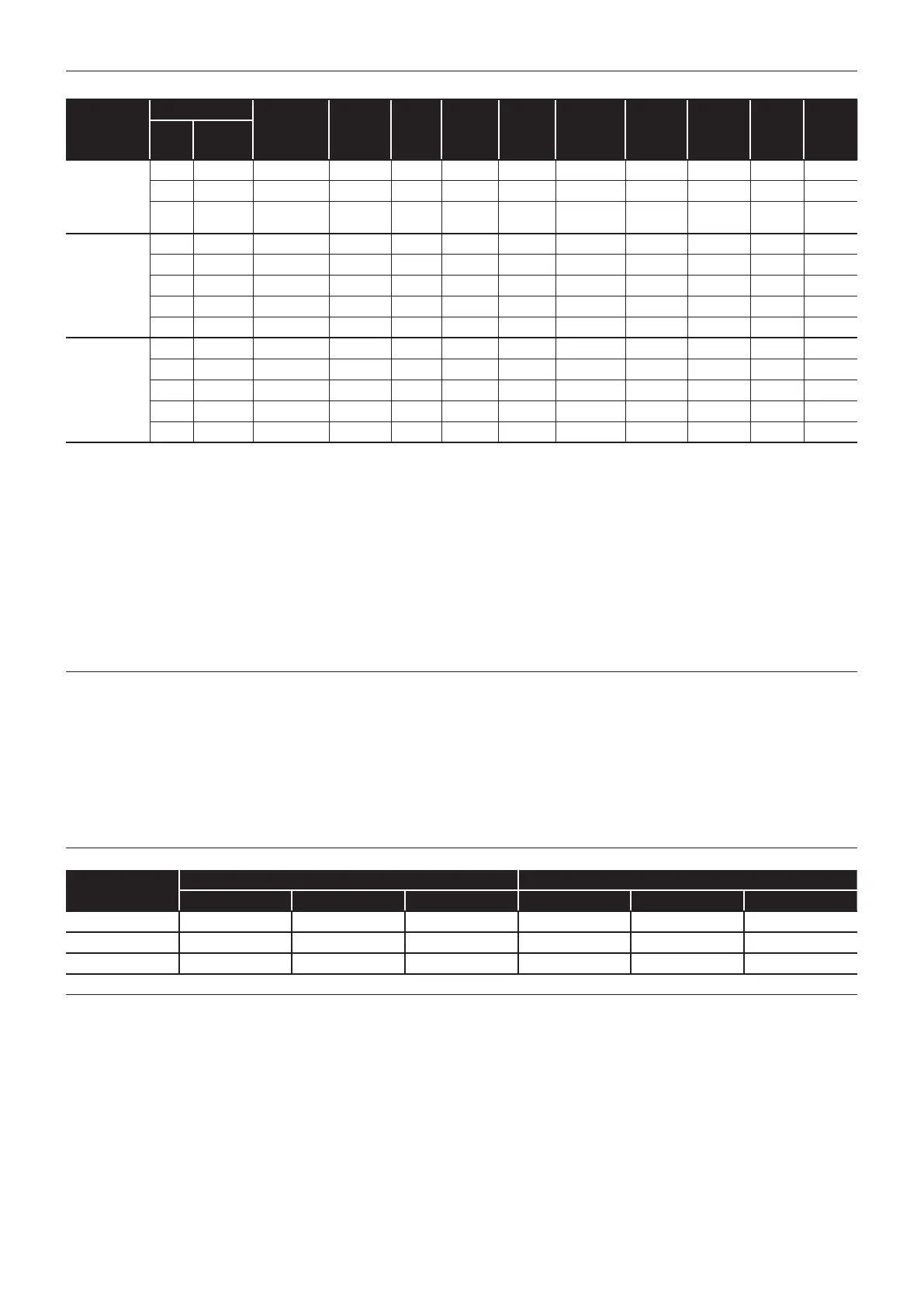

2.2 BURNER SETTINGS

Table 2-2: Burner settings

Boiler

models

(burner

type)

Heat output

Nozzle

Oil

pressure

(bar)

Smoke

No.

Burner

head

type

Burner

head/

air disc

setting

Distance

D ¹⁰ (mm)

Fuel

ow rate

(kg/h)

Flue gas

temp.

(°C)

CO

2

(%)

Flue

gas

VFR ‡

(m³/hr)

(kW) (Btu/h)

Boiler House

15-26

(Riello

RDB2.2 BX

V15/26)

15.0 51,200 0.45/80°EH 8.0 0 - 1 BX 500 Disc: B 11.5 1.25 60 - 65 12.5 16.0

21.0 * 71,600 0.60/60°ES 8.0 0 - 1 BX 500 Disc: C 13 1.75 65 - 70 12.5 23.0

26.0 88,700 0.75/60°ES 8.5 0 - 1 BX 500 N/A 15 2.16 75 - 80 12.5 28.5

Boiler House

26-46

(Riello

RDB2.2 BX

V36/46)

26.0 88,700 0.75/60°ES 8.0 0 - 1 BX 700 Disc: B 15 2.16 65-70 12.5 28.5

31.0 105,700 0.85/60°ES 9.0 0 - 1 BX 700 Disc: C 16 2.58 70-75 12.5 34.5

36.0 122,800 1.00/60°ES 9.0 0 - 1 BX 700 N/A 17.5 3.09 75 - 80 12.5 39.5

41.0 * 140,000 1.10/60 °ES 10.0 0 - 1 BX 700 N/A 17.5 3.52 80 - 85 12.5 45.5

46.0 157,000 1.25/60°S 8.0 0 - 1 BX 700 N/A 20 3.95 85 - 90 12.5 51.0

Boiler House

46-70

(Riello

RDB3.2

VORT 70)

46.0 157,000 1.25/80°S 8.0 0 - 1 GIB Head: 0 - 3.92 75 - 80 12.5 51.0

52.0 177, 5 0 0 1.35/80°S 9.5 0 - 1 GIB Head: 0 - 4.43 75 - 80 12.5 58.5

58.0 197, 9 0 0 1.35/45°H 10.0 0 - 1 GIB Head: 0 - 4.97 75 - 80 12.5 66.0

64.0 * 218,300 1.50/45°H 10.5 0 - 1 GIB Head: 2 - 5.49 75 - 80 12.5 72.5

70.0 238,800 2.00/45°S 8.5 0 - 1 GIB Head: 2 - 6.00 75 - 80 12.5 78.5

Notes:

‡ Flue gas VFR: Flue gas volumetric ow rate

1. The data given above is approximate only and is based on the boiler being used with a low level balanced ue.

2. The above settings may have to be adjusted on site for the correct operation of the burner.

3. Gas Oil is NOT suitable for use with Grant Vortex boiler range

4. The ue gas temperatures given above are ± 10%.

5. When commissioning, the air damper must be adjusted to obtain the correct CO

2

level.

6. * Factory settings: 15-26 - 21kW, 26-46 - 41kW, 46-70 - 64kW.

7. The combustion door test point may be used for CO

2

and smoke readings only. Do not use this test point for temperature or eciency readings.

8. When setting the 15-26 to 15kW, the air adjuster disc requires repositioning. Refer to Section 10.4 (air adjuster disc).

When setting the 15-26 to 26kW, the air adjuster disc is not required. Refer to Section 10.4 (air adjuster disc).

9. When setting the 26-46 to either 26kW or 31kW, the burner air adjuster disc (Grant UK product code: Z20094349) must be tted and positioned to the

correct disc setting, as shown in Table 2-2 above. Refer to Section 10.4 (air adjuster disc). This disc is NOT supplied with the boiler but can be obtained

free-of-charge by contacting Grant UK.

10. When setting the 46-70 to 46, 52 or 58kW the burner head requires repositioning. Refer to Section 10 (Commissioning).

11. The installer must amend the boiler data label if the output is changed.

12. Refer to Section 10.2 for information on how to set Distance D (Figure 10-5).

2.3 FLUE GAS ANALYSIS

To allow the boiler to be commissioned and serviced, the boiler is supplied with a combustion test point on the front cleaning door.

When this test point is used please note the following:

• The test point is for CO

2

and smoke readings only.

• The boiler eciency and temperature must be taken from the ue test point on high level, vertical and conventional ue adaptors.

• Concentric low level ues do not contain a test point. The temperature and eciency readings must be taken from the ue terminal.

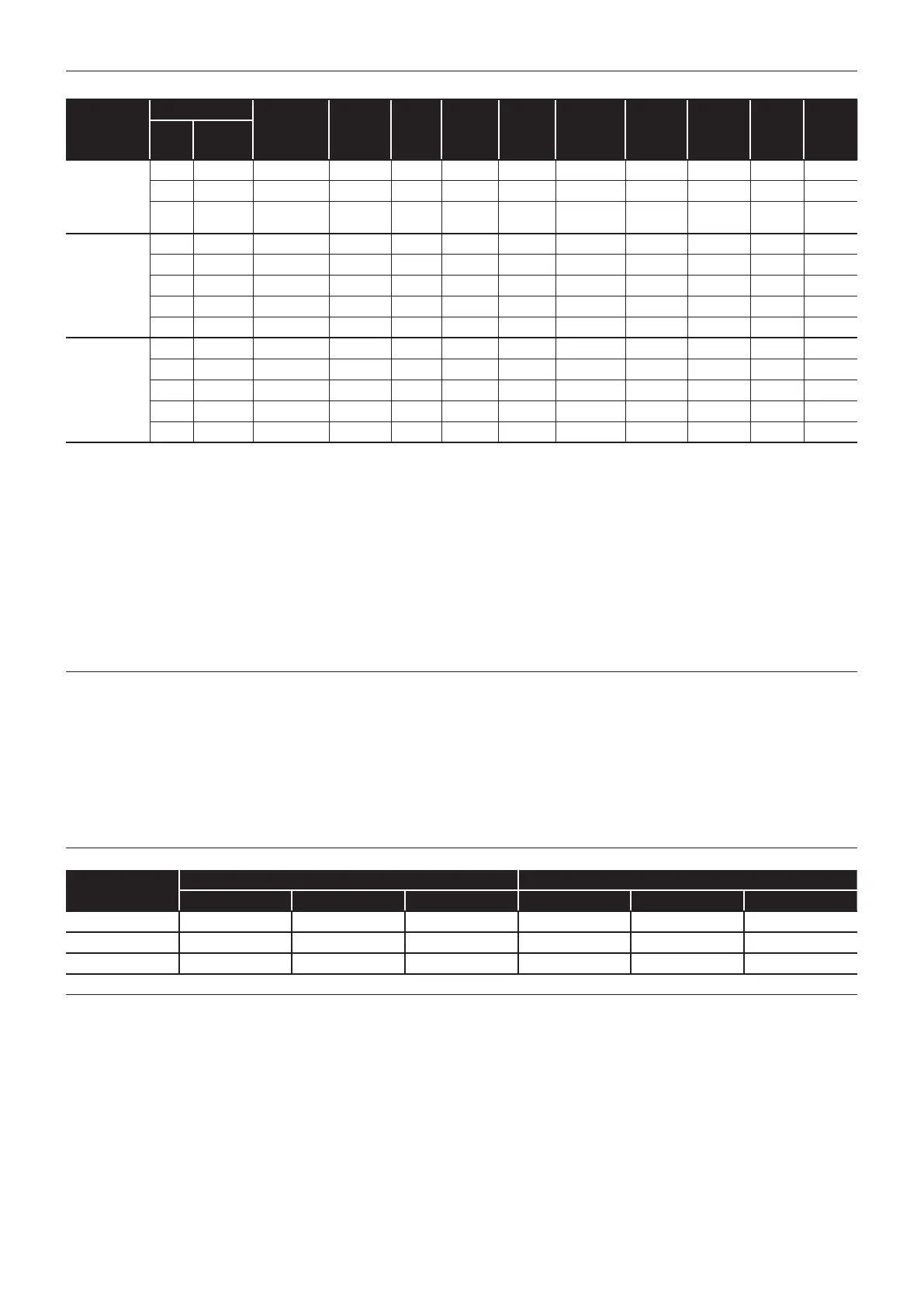

2.4 WATER CONNECTIONS

Table 2-3: Water connections

Boiler model

Flow connection Return connection

Size Fitting Supplied Size Fitting Supplied

15-26 1ʺ BSP BSP female Fitted 1ʺ BSP BSP female Fitted

26-46 28mm pipe* Compression In ttings kit* 1ʺ BSP BSP female Fitted

46-70 1¼ʺ BSP BSP female Fitted 1¼ʺ BSP BSP female Fitted

* The pipe and compression tting are placed under the blanking plate that covers the ow connection.

Loading...

Loading...