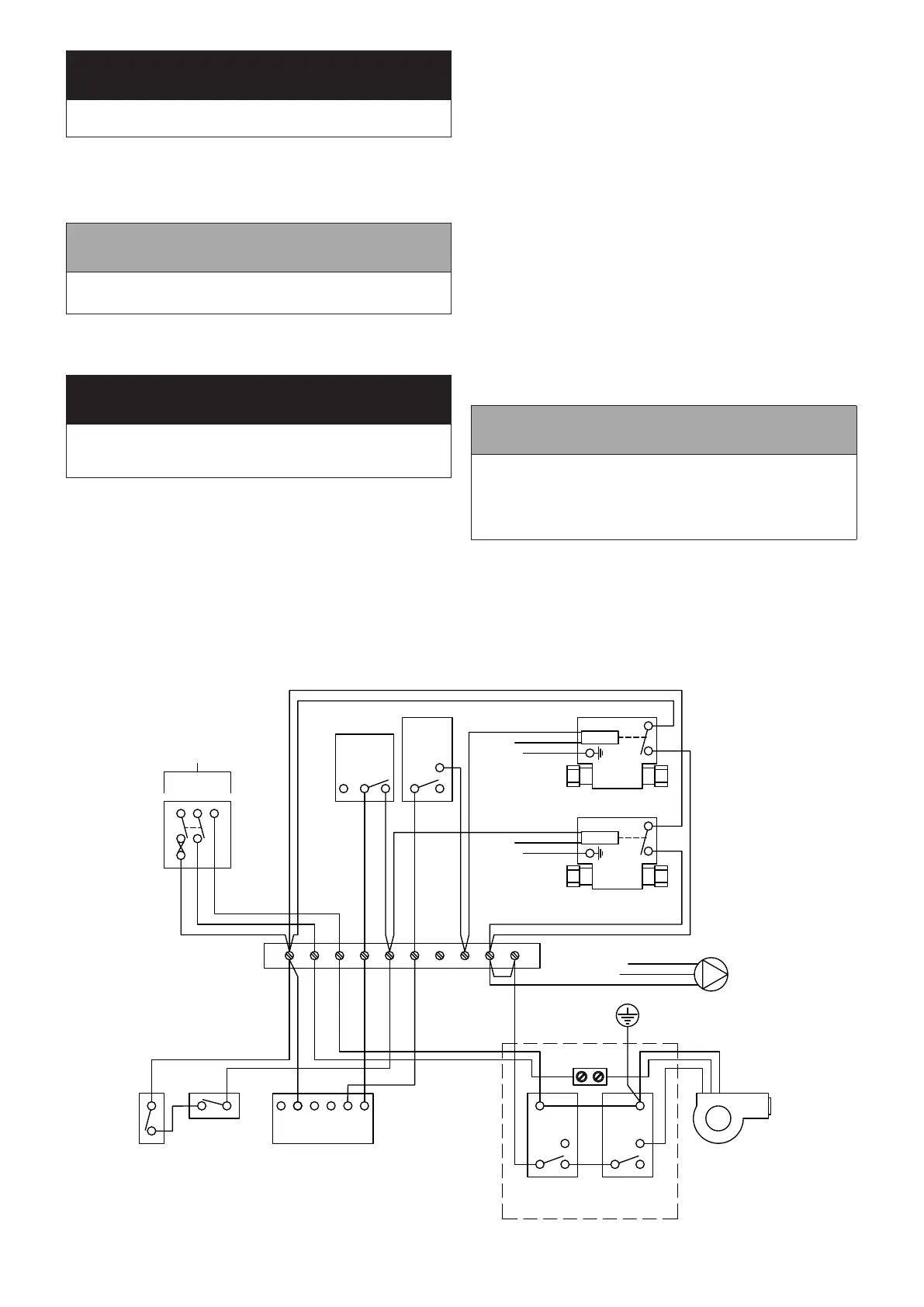

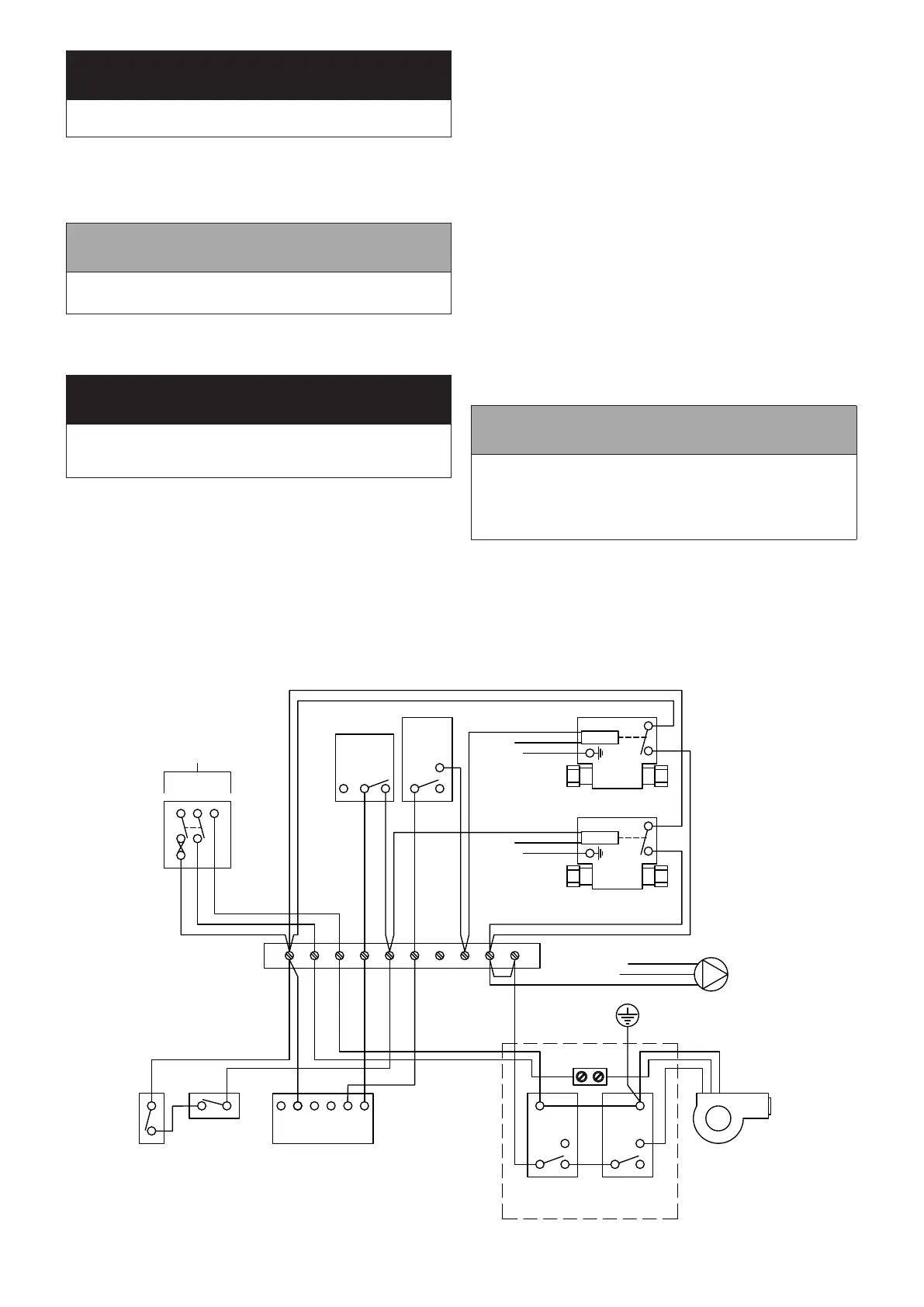

Section 8: ElectricalPage 24

2-Port Zone Valve

Motor

Room

Stat

2 1 3

230V

50HZ

L N E

5A

2-Port Zone Valve

Motor

1 2 3 4 5 6 7 8 9 10

HTG

HW

Wiring

Centre

Grey

Orange

Orange

Brown

Blue

Green/Yellow

Green/Yellow

Brown

Blue

Brown

Blue

Green/Yellow

Cylinder

Stat

1

C

2

Blue

Green/Yellow

Brown

E

N

L

Link

Pump

N

2-Channel

Programmer

L

Frost

Thermostat

Pipe Stat

(If fitted)

OFFOFF ON ON

HW HT HW HT

Overheat

Stat

1

C

2

Control

Stat

1

C

2

Link

Burner

L N E

Earth Stud on

top of Boiler

Green/Yellow

Blue

Brown

Blue

Green/Yellow

Refer to Figure 8-3 for connection details

Figure 8-1: 2 x 2-port valve control system

8.4 WIRING DIAGRAMS

! WARNING !

DO NOT connect the neutral wires to either of the two

thermostats.

6. There are NO connections to terminal 1 on the overheat

thermostat and terminal 2 on the control thermostat.

7. Position the support bushes so as not to strain the

connections when the cover is replaced. Place the cover in

position locating the bushes at the same time.

! NOTE !

It may be necessary to rotate the thermostat knob to

engage it on the operating spindle as the cover is replaced.

8. Secure the cover in position by tightening the three screws.

Tighten the cable support bush nuts to secure the cables.

9. Ensure that all external wiring is adequately supported.

! WARNING !

After completing electrical connections and before

reconnecting the electrical supply to the boiler, ensure the

dual thermostat cover is properly secured.

10. Re-connect the electrical supply and check operation of

heating system controls (programmer, room thermostats,

etc.).

11. Refer to Instructions provided with the programmer for

operation and setting.

12. Leave the Programmer and Thermostat Instructions with the

user after installation for their future reference.

BURNER LEAD PLUG/SOCKET CONNECTOR

On all models, the electrical cable between the boiler control

panel and burner is now tted with an in-line 3-way plug

and socket connector. This enables the burner to be easily

disconnected from the boiler control panel for ease of removal

and servicing.

8.3 FROST PROTECTION

For additional protection of either the entire heating system, or

the boiler and localised pipework, it is recommended that a frost

thermostat be installed.

Refer to Figures 8-1 & 8-2 (as appropriate) for connection details.

To protect the heating system, the frost thermostat should be sited

within the house in such a place that it can detect any rise and fall

in the ambient air temperature, i.e. in a room with a radiator.

Where the frost thermostat is installed outside the house (to

protect a boiler installed in an external boiler room or garage) or

in an attic, it is recommended that it be used in conjunction with a

pipe thermostat to avoid unnecessary and wasteful overheating of

the property.

The pipe thermostat should be located on the boiler return pipe,

and set to operate at 25°C.

! NOTE !

For total system protection against freezing, particularly

during extended periods without electrical power, Grant

recommend the use of a combined heating system

antifreeze and corrosion inhibitor, used in accordance with

the manufacturer’s instructions.

Loading...

Loading...