5.1 GENERAL

The ow and return pipework can be routed to either side of the

boiler, dependant on the type and direction of the ue system

used.

For condensate disposal pipework refer to Section 6.

A drain cock is supplied in the accessories pack and should be

tted at the bottom on the front of the boiler to allow the boiler to

be drained.

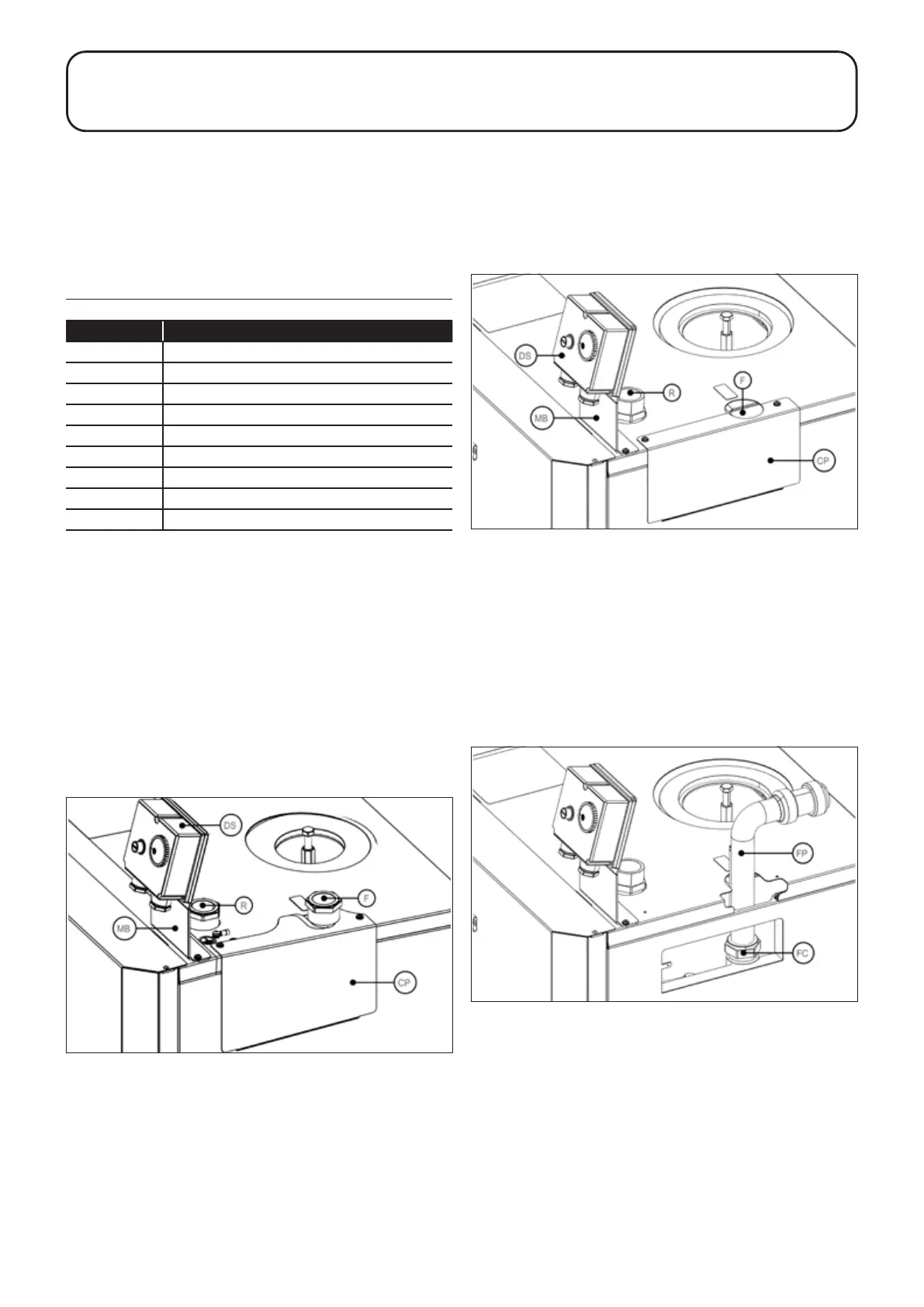

Key to diagrams

Key

F Flow

FP Flow pipe

FC Flow connection

R Return

MB Mounting bracket

DS Dual stat

CP Removable cover plate

P Pockets

SP Split pin

5.2 15-26 MODELS

FLOW CONNECTION

A 1ʺ BSP socket is provided for the boiler ow connection. This is

located on the top of the boiler towards the right hand side. Refer

to Figure 5-1.

The ow pipe from the boiler will need to be vented as it is the

highest point on the primary heat exchanger.

RETURN CONNECTION

A second 1ʺ BSP socket is provided for the boiler return

connection. This is located on the top of the boiler towards the

front on the right hand side. Refer to Figure 5-1.

The return pipe to the boiler will also need to be vented as it is the

highest point on the secondary heat exchanger.

Figure 5-1: 15-26 models - dual stat/mounting bracket, ow and

return connections and removable cover plate

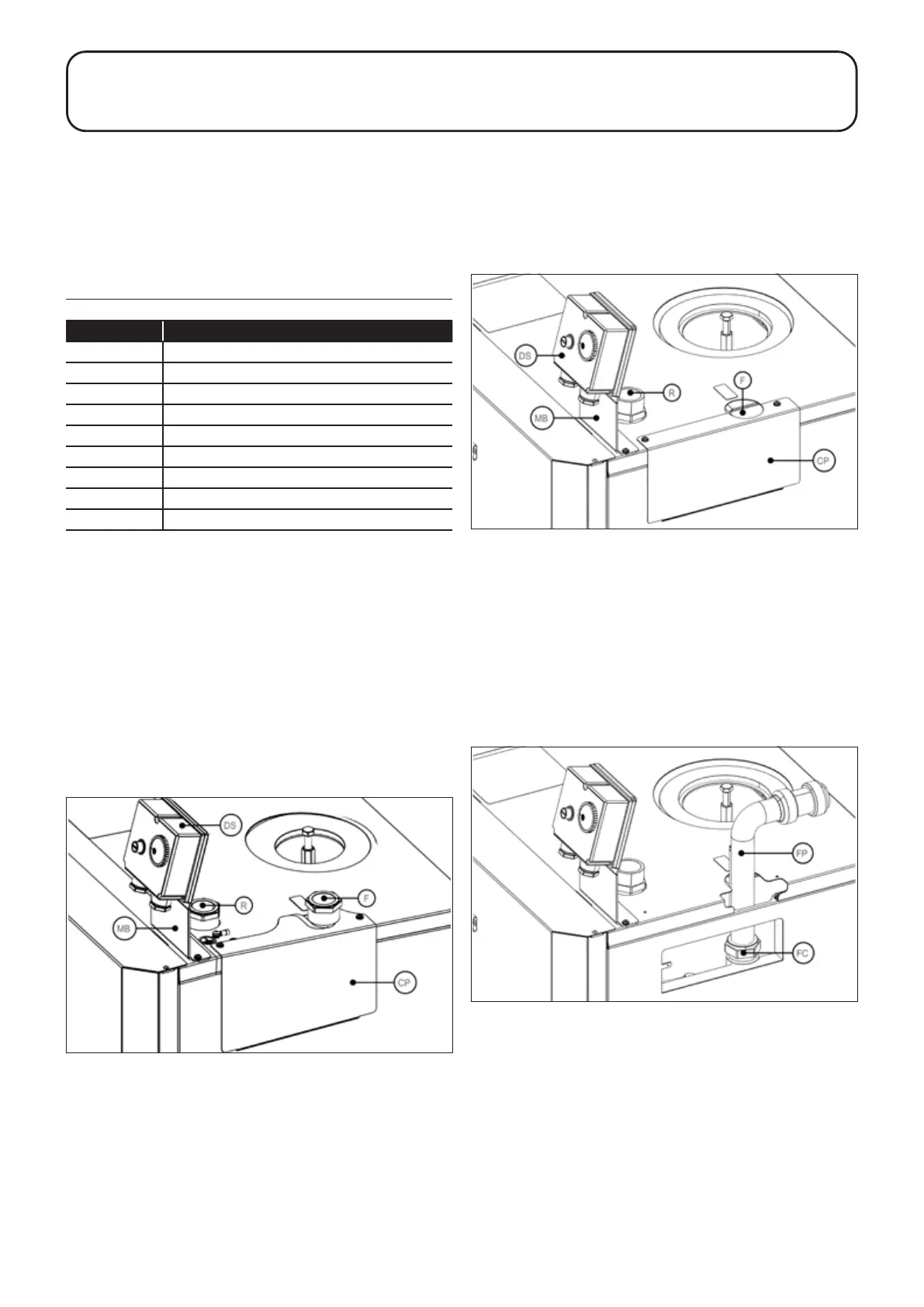

5.3 26-46 MODEL ONLY

FLOW CONNECTION

A 28mm compression connection is supplied for the boiler ow

connection. This is located on the right hand side of the boiler

behind a removable cover plate. To gain access to the connection,

unscrew and remove the two screws from the top ange of the

cover plate and remove cover plate from boiler. Refer to Figure

5-2.

Figure 5-2: 26-46 model - dual stat/mounting bracket, ow and

return connections and removable cover plate

A bent 28mm ow pipe, with two thermostat pockets, is supplied

with the boiler to be tted into the ow connection, as follows:

1. With the cover plate removed, loosen the compression nut

and t the longer leg of the bent ow pipe into the connection.

2. Ensure that the pipe is vertical and fully pushed into the

connection.

3. With the open end of the ow pipe pointing in the required

direction (see below), fully tighten the compression nut. Refer

to Figure 5-3.

4. Replace cover plate and secure with the two screws

previously removed.

Figure 5-3: 26-46 model - ow pipe tted (cover plate removed)

The direction of the bent ow pipe will depend on the ue system

being used with the boiler.

If a Grant low level balanced ue (Yellow System) or external

balanced ue system (Green System) is used, the ow pipe must

be positioned as follows:

• If the ue points towards the right of the boiler (viewed from

the front), the ow pipe must be set to point either to the right

or to the front of the boiler to avoid clashing with the ue.

• If the ue points towards the rear of the boiler, the ow pipe

must be set to point either to the rear, to the right or to the

front of the boiler to avoid clashing with the ue.

• If the ue points towards the left of the boiler (viewed from

the front), the ow pipe must be set to point either to the rear,

to the right or to the front of the boiler to avoid clashing with

the ue.

Section 5: Pipe Connections Page 17

5 PIPE CONNECTIONS

Loading...

Loading...