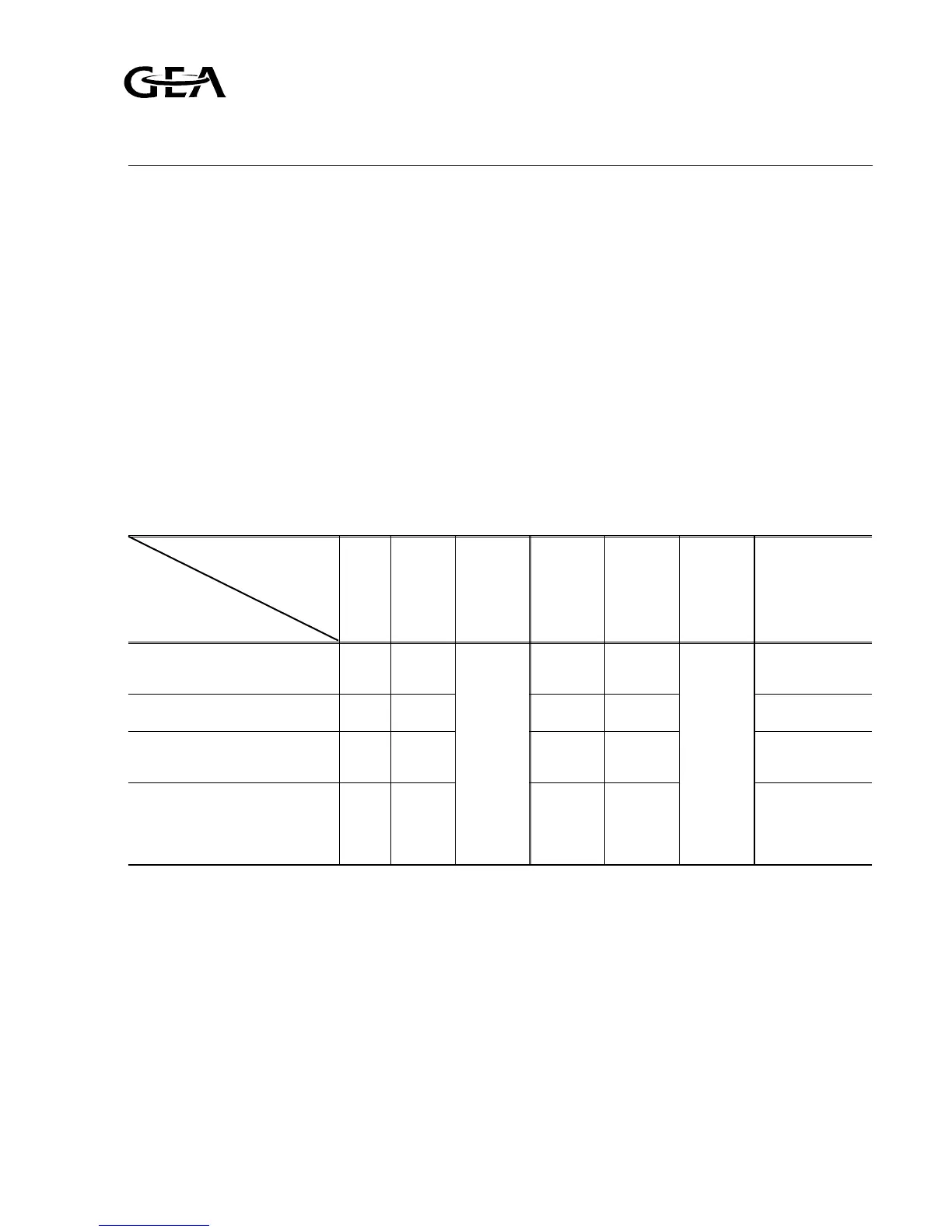

B2.2 First maintenance

The maintenance schedule below indicates after

how many operating hours maintenance

operations have to be carried out. This schedule

can be regarded as a directive, based on the

experience gained with a large number of

compressors.

For most of the maintenance operations the

compressor must be put out of action. In order to

avoid that this should take place at inconvenient

times, the operations should as much as possible

be affected during a stand-still period. The

schedule has been drawn up in such a way that

several operations can be carried out

sumultaneously, which results in reduced

maintenance costs.

MAINTENANCE SCHEDULE

Number of

operating

hours

100

1

) 2500

2

)

5000

7500

2

)

10,000 10,100 12,500

2

)

15,000

17,500

2

)

20,000 etc.

Maintenance

Cleaning of oil suction filter and

renewal of oil discharge filter

(ref. to par. 9.6).

$$

Major inspection to be carried

out by installation engineer

$$

Major inspection to be carried

out by installation engineer

Cleaning of suction gas strainer

(ref. to par. 9.7).

$$

$

$

Inspection of suction and discharge

valves

(ref. to par. 9.8)

$$

Draining and change of oil

3)

(ref. to par. 9.5).

$$ $ $

1

) time dependent on pollution.

2

) Only for NH

3

-compressors

3

) In the case of a possible rapid pollution of the oil, it should be drained and renewed sooner than at the times given

Refrigeration Division

Grasso

B: INSPECTION, MAINTENANCE

AND TROUBLE SHOOTING

v001.99.01.en Installation and Maintenance Manual RC(U)6 B1.3

Loading...

Loading...