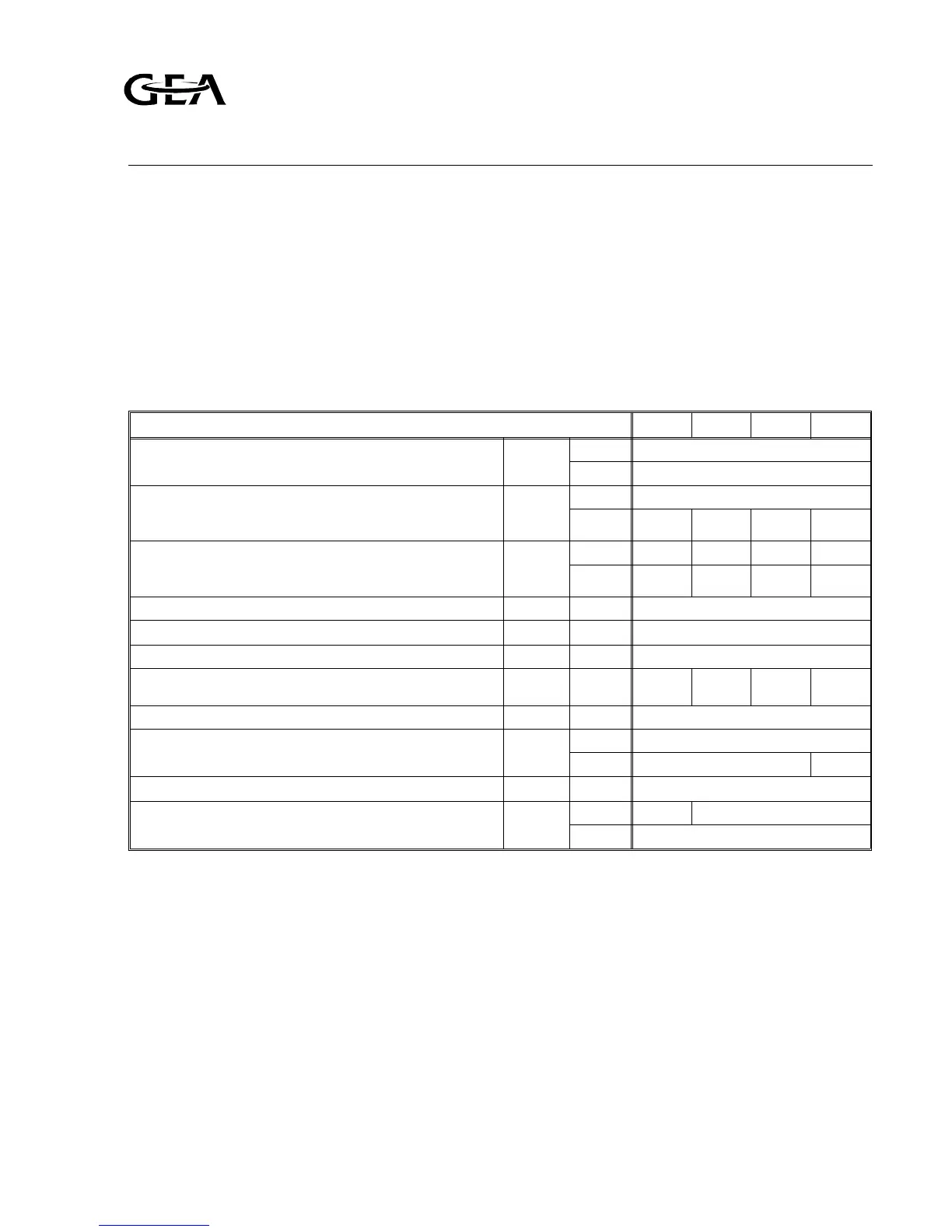

5.1 INDIVIDUAL LIMITS OF OPERATION

With an operating compressor several working

conditions arise which one by one are bound to certain

limits. These so-called “individual operation limits” are

determined by structural limitations of the compressor

itself or they are based on thermodynamic and

practical considerations. They apply to both single-stage

and booster compressors.

When operating the compressor, none of the limits of

operation as stated in the table 5.1 below must be

exceeded.

Note:

In practice it is not so much the individual limits

of operation, described in this paragraph, as

combinations of them that are decisive for the

conditions under which a compressor may

operate. To check the various possibilities in this

respect, use should be made of the “fields of

application” according to the figures 5.1 to 5.5.

REFRIGERANT NH

3

R22 R134a R404A

Compressor speed n min

-1

min. 800

max. 1500

Suction pressure

= evaporating pressure

= crankcase pressure

1

)p

o

bar(a)*

min. 0.3

max. 6.2 6.8 6.2 6.0

Evaporating temperature

= saturation temperature

at suction pressure

1

)t

o

o

C

min. -55.1 -63.8 -50 -68.1

max. +10.2 +10.0 +22.6 -0.1

Actual suction temperature

2

)t

a

o

Cmin. -50

Suction superheat

∆t

o

Kmin. 5

Discharge pressure = condensing pressure

3

)p

c

bar(a)* max. 26

Condensing temperature

= saturation temperature at discharge pressure

t

c

o

C max. +59.8 +63.2 +79.5 +55.6

Discharge temperature

4

)t

e

o

Cmax. +155

Pressure ratio (p

c

/p

o

)

5

)j -

min. 1.5

max. 10 15

Pressure difference (p

c

-p

o

)

6

)

∆p

bar* max. 24

Oil temperature in crankcase

7

)t

oil

o

C

min. +20 +30

max. refer to pragraph 4.3

Table 5.1

* 1 bar = 10

5

N/m

2

= 100 kPa = 1.02 kgf/cm

2

= 14.5 psi.

1

) The minimum values of p

o

and t

o

are only of importance for

booster applications. In that case the maximum value of t

o

also

applies to the saturation intermediate temperature (t

m

).

For halocarbon refrigerants the maximum values of p

o

and t

o

are

based on a density of the suction gas of 30 kg/m

3

.

During start-up and immediately thereafter, p

o,max.

may be

exceeded slightly [up to 11 bar(a) max.] and temporarily, but no

longer than about 5 minutes.

The maximum static crankcase pressure during compressor

standstill is 21.5 bar(a).

2

) Only of importance for booster application.

3

) This pressure is also the maximum allowable pre-set value of the HP

safety switch.

4

) This is the actual discharge temperature, measured directly in the

gas flow inside the cylinder head covers, just above the discharge

valves.

5

) Pressure ratio limits are not absolute but arbitrary values based on

practical considerations.

6

) The standard built-in overflow safety valve between suction and

discharge chamber in the compressor housing has been factory-set

to 24.5 (+10%) bar to prevent advanced opening during normal

operation at ∆p ≤ 24 bar.

7

) Indicated minimum value is the lowest oil temperature at which

compressors are allowed to be started.

The maximum oil temperature depends on the operating

conditions of the compressor, the oil type used and (for halocarbon

refrigerants only) the solvability of the refrigerant in the oil. A

minimum actual oil viscosity of 15 cSt is always required.

When using ammonia as refrigerant, the maximum oil temperature

will be exceeded only when a combination occurs of high ambient

temperature, high suction superheat and part-load operation. In

that case an oil cooler is required. A water-cooled oil cooler always

form part of the standard delivery of a RC6W-compressor.

Refrigeration Division

Grasso

5. LIMITS OF OPERATION AND

FIELDS OF APPLICATIONS

v001.99.01.en Installation and Maintenance Manual RC(U)6 page C3.1

Loading...

Loading...