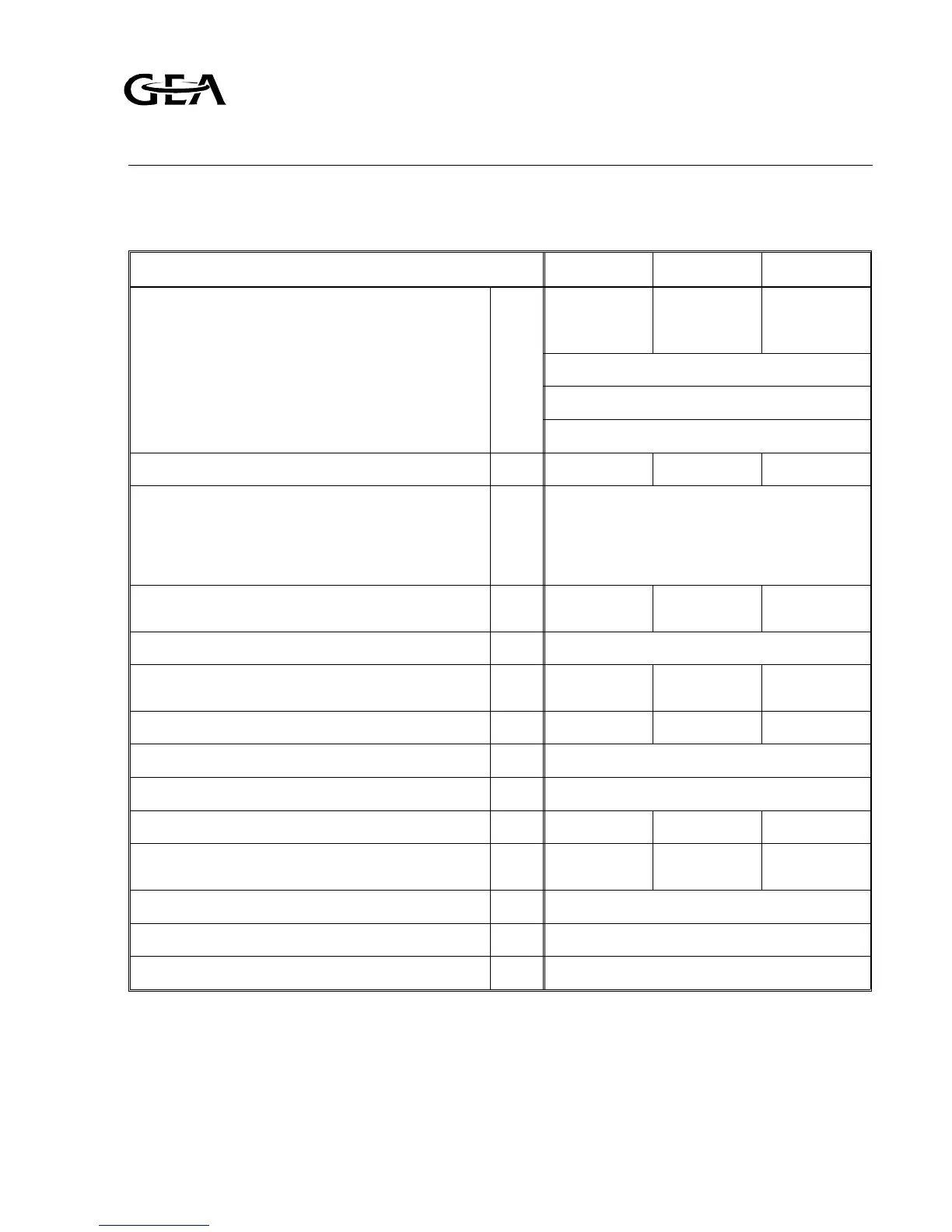

4.1 TECHNICAL DATA

COMPRESSOR TYPE RCF46/RCA46 RCF66/RCA66 RCF86/RCA86

Number of cylinders z 4 6 8

Cylinder arrangement 2 x V 2 x W 2 x VV

Cylinder bore D mm 85

Piston stroke S mm 66

Direction of rotation both directions permitted

Swept volume at full-load and n = 1450/min V

s

m

3

/h 130.3 195.5 260.7

Standard compressor speeds (with V-belt drive)

motor speed 1450/min (50 Hz)

nmin

-1

810 - 855 - 905 - 1015 - 1140 - 1215 - 1285 - 1450

motor speed 1750/min (60 Hz) 800 - 875 - 980 - 1030 - 1095 - 1225 - 1380 - 1465

Standard steps of capacity control (expressed in

percentage of full-load swept volume)

1

) % 100 - 50 100 - 67 - 33 100 - 75 - 50 - 25

Main dimensions, connections and required free space Refer to par. 4.2.

Mass of bare compressor (without

flywheel and other accessories)

kg 280 345 400

Oil charge in crankcase (centre line of sight glass)

2

)dm

3

9.2 (8.5) 10.0 (9.3) 10.8 (10.1)

Oil type to be used Refer to par. 4.3.

Starting torque Refer to par. 4.7.

Friction power at n = 1450/min and 55

o

C oil temperature

3

)P

w

kW 1.10 1.53 2.22

Mass moment of inertia of crank mechanism

(without flywheel)

4

)I

d

kg

.

m

2

0.0361 0.0421 0.0478

Centre of gravity and free forces and moments

5

) Refer to par. 4.4.

Torsional elastic substitute systems of crankshaft

6

) Refer to par. 4.5.

Sound rating Refer to par. 4.8.

Table 4.1 Technical data

1

) See also Chapter 3.

2

) The figures between brackets indicate the smaller oil charge for the

RCA6W compressors due to the presence of an oil cooler.

3

) P

w

is needed for calculating the condenser capacity Q

c

.

See also paragraph 4.6.

P

w

= (n/1000).(0.02293.z

2

- 0.08207.z + 0.71931).

4

) The mass moment of inertia I

d

, expressed in SI-units, is required to

determine the so-called coefficient of speed fluctuation.

5

) The centre of gravity and free forces and moments are of

importance when calculating a vibration-free mounting of the

compressor.

6

) These crankshaft substitute systems are required to carry out

torsional vibration calculations in case the compressor is driven by

an internal combustion engine.

Refrigeration Division

Grasso

4. GENERAL DATA

v001.99.01.en Installation and Maintenance Manual RC(U)6 page C2.1

Loading...

Loading...