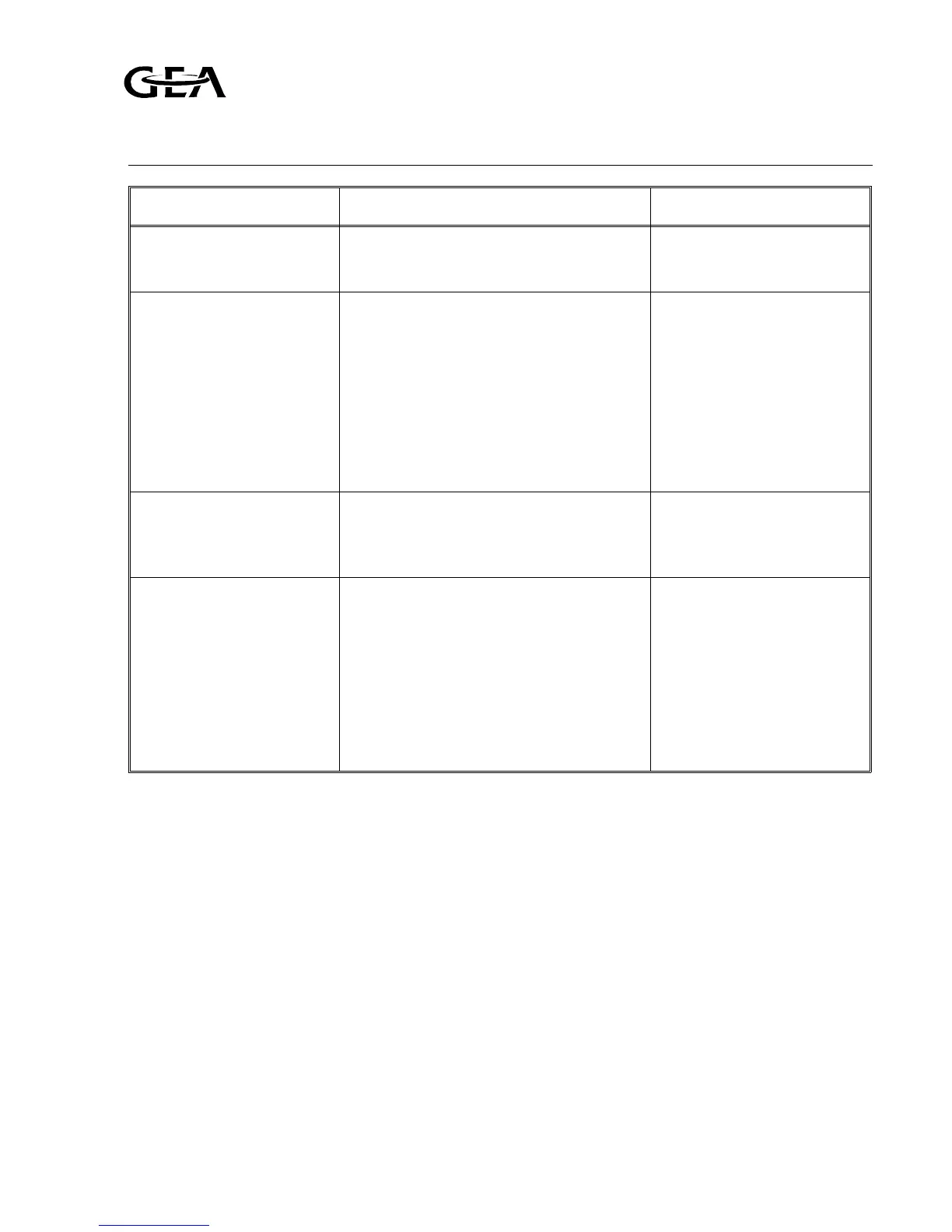

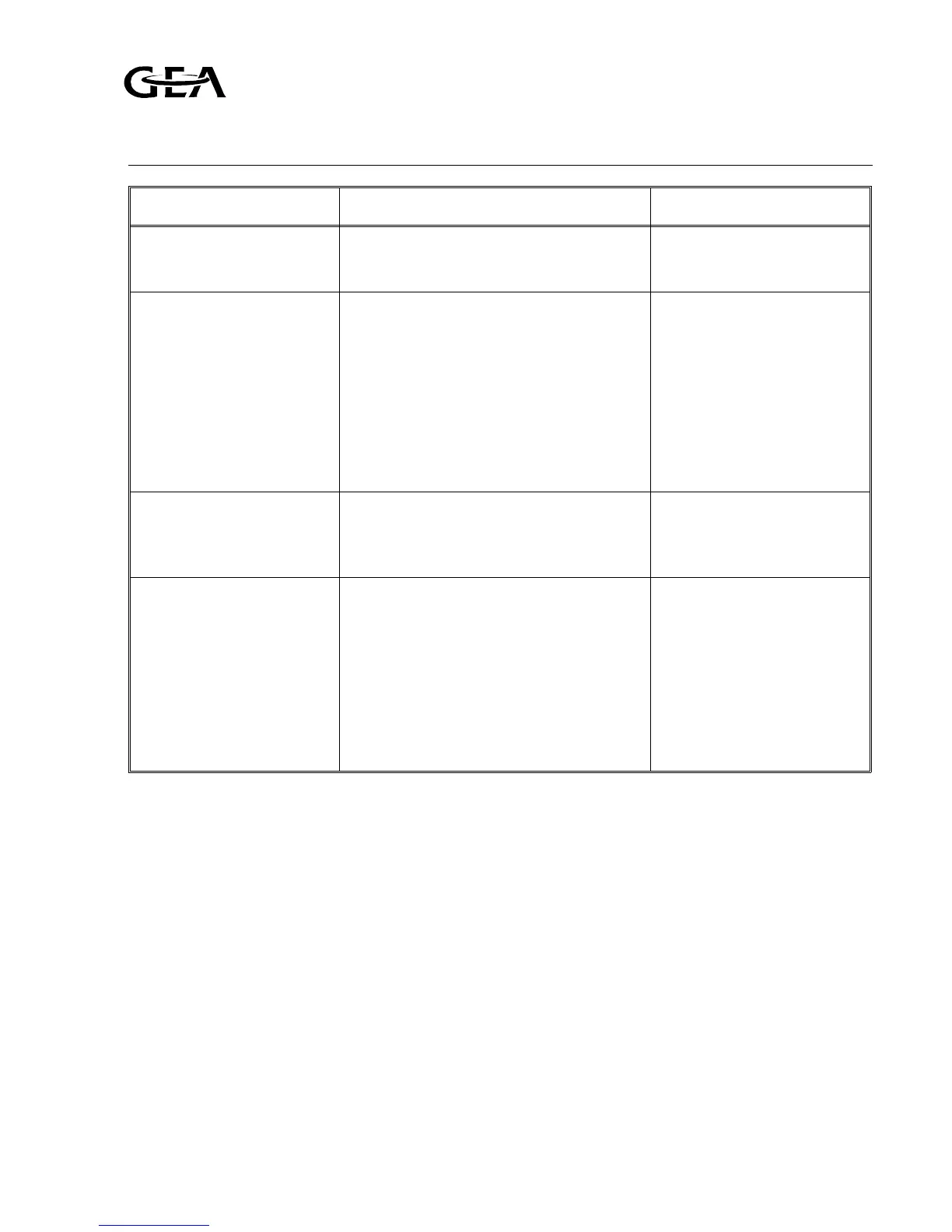

FAULT CAUSE REMEDY

F Cylinders inactive while com-

pressor is operating

1. Incorrect wiring of capacity control 1. Refer to the "Engineering Data"

G Too high oil consumption 1. Type of oil not according to oil lubrication oil

table (too thin oil)

1. Change oil type

2. Compressor operates unloaded too frequently 2. Refer to design calculations

3. No return from oil separator* 3. Check the operation of float

valve in oil separator

4. Tube of pressure equalizing obstructed 4. Clean tube

5. Worn out oil scraper ring(s) 5. Replace ring(s)

6. Loss of oil due to leakage 6. Repair

7. Leaking shaft seal (max. 1 cc/hr) 7. Repair shaft seal

8. Oil level in crankcase too high 8. Refer to §B2

H Too high oil pressure during

normal operation at working

temperature

1. Lubricating oil pressure regulator not adjusted

properly or defective

1. Re-adjust or renew

2. Defective oil pressure and/or suction pressure

gauge (if present)

2. Repair or replace

J Too low lubricating oil pressure 1. Too little oil in crankcase 1. Top up oil

2. Disturbed oil circuit:

Oil suction and/or discharge filter is dirty

2. Renew the element of oil

suction filter and/or oil

discharge filter

3. Lubricating oil pressure regulator not adjusted

properly or defective

3. Re-adjust or renew

4. Liquid refrigerant in crankcase 4. See E

5. Defective oil pressure and/or suction pressure

gauge (if present)

5. Repair or renew

6. Worn bearings 6. Renew bearings

*) During the initial start-up, the oil separator (if present) consumes oil before the first oil will be returned.

Refrigeration Division

Grasso

B: INSPECTION, MAINTENANCE

AND TROUBLE SHOOTING

v001.99.01.en Installation and Maintenance Manual RC(U)6 B1.9

Loading...

Loading...