DC INVERTER MULTI VRF INSTALLATION

131

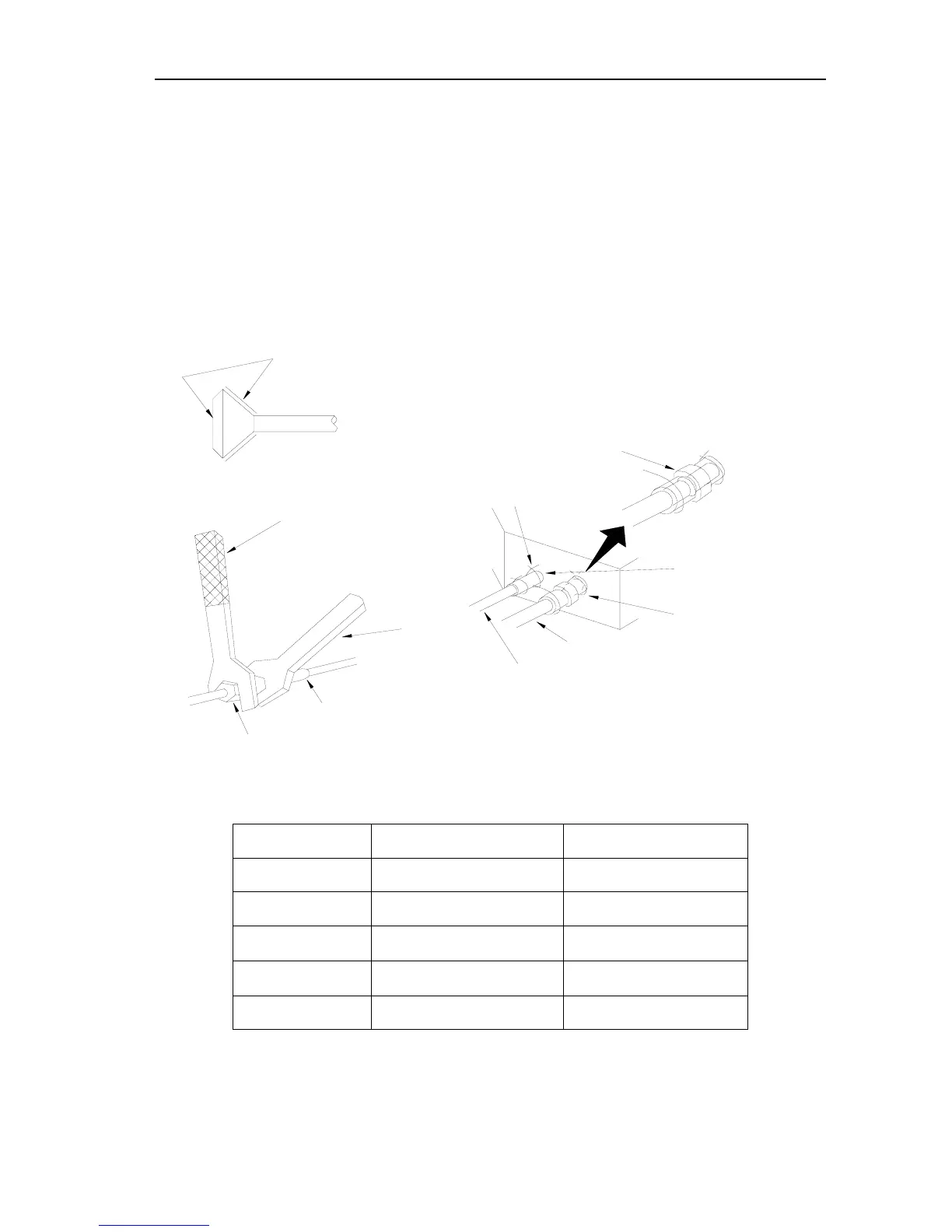

wrench. as shown in fig.3.

☆ When connect, smear both inside and outside of the flare nut with freeze motor oil, screw it by hand and

then tighten it with spanner.

☆ Refer to form 1 to check if the wrench had been tightened (too tight would mangle the nut and lead

leakage).

☆ Examine the connection pipe to see if it had gas leakage, then take the treatment of heat insulation, as

shown in the fig.3.

☆ Only use median sponge to entwine the wiring interface of the gas pipe and heat preservation sheath of

the gas collection tube.

Heat preservation

sheath of gas collection

tube (attachment)(for

gas tube)

Heat preservation

sheath of liquid inlet

tube (attachment) (for

liquid tube)

Flare nut

Wiring interface

Spanner

Liquid inlet tube

Gas collection tube

Torque wrench

Median sponge (attachment)

(entwine the wiring interface

with seal mat)

Thread fasten(x4)

Smear freeze motoroil

here

Fig.3

Form 1: The tightening torque needed for tightening nut

Diameter(Inch) Surface thickness(mm)

Tightening torque (N.m)

φ1/4’’ ≥0.5 15-30 (N·m)

φ3/8’’ ≥0.71 30-40 (N·m)

φ1/2’’ ≥1 45-50 (N·m)

φ5/8’’ ≥1 60-65 (N·m)

φ3/4’’ ≥1 70-75 (N·m)

● Drainage hose

1. Install the drain hose

Loading...

Loading...