DC INVERTER MULTI VRF INSTALLATION

150

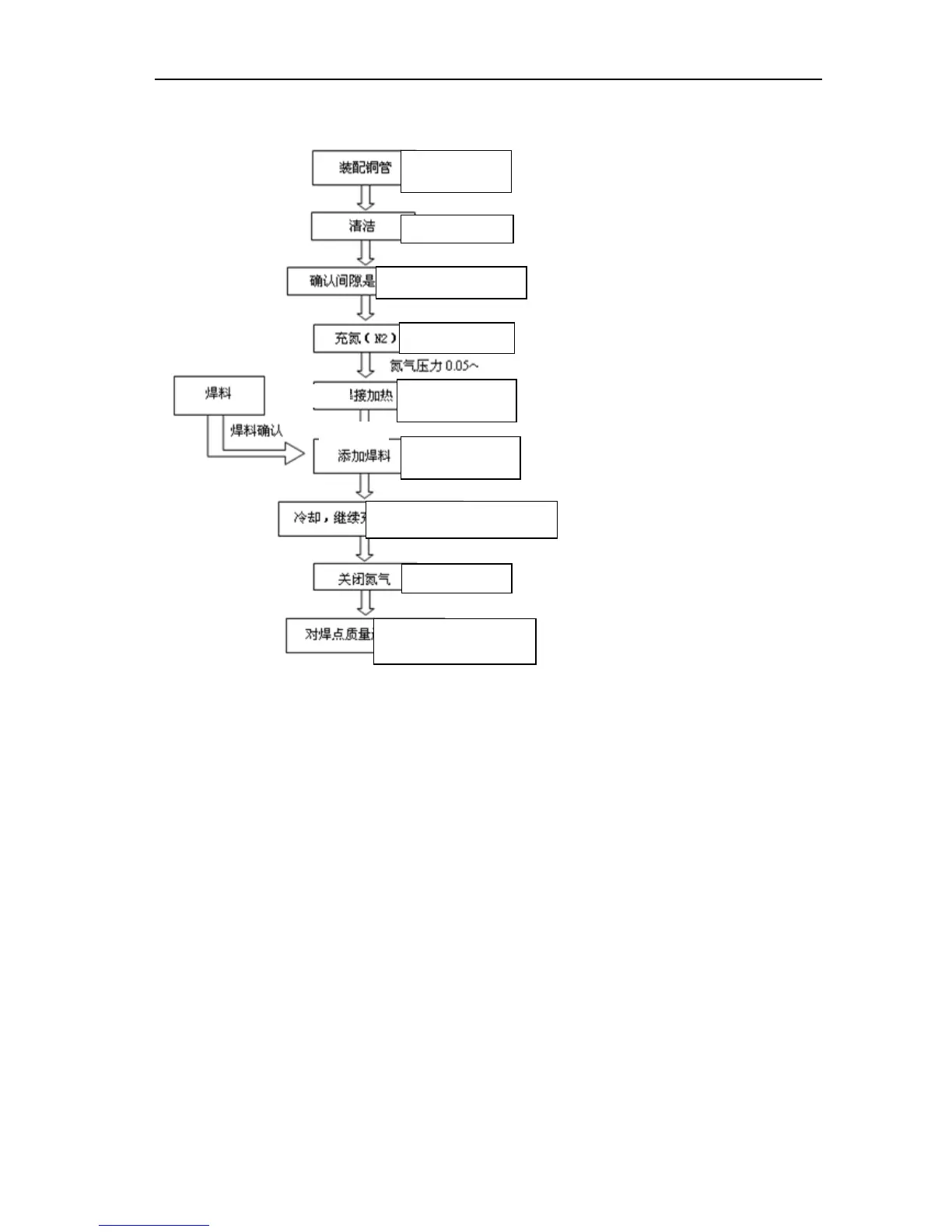

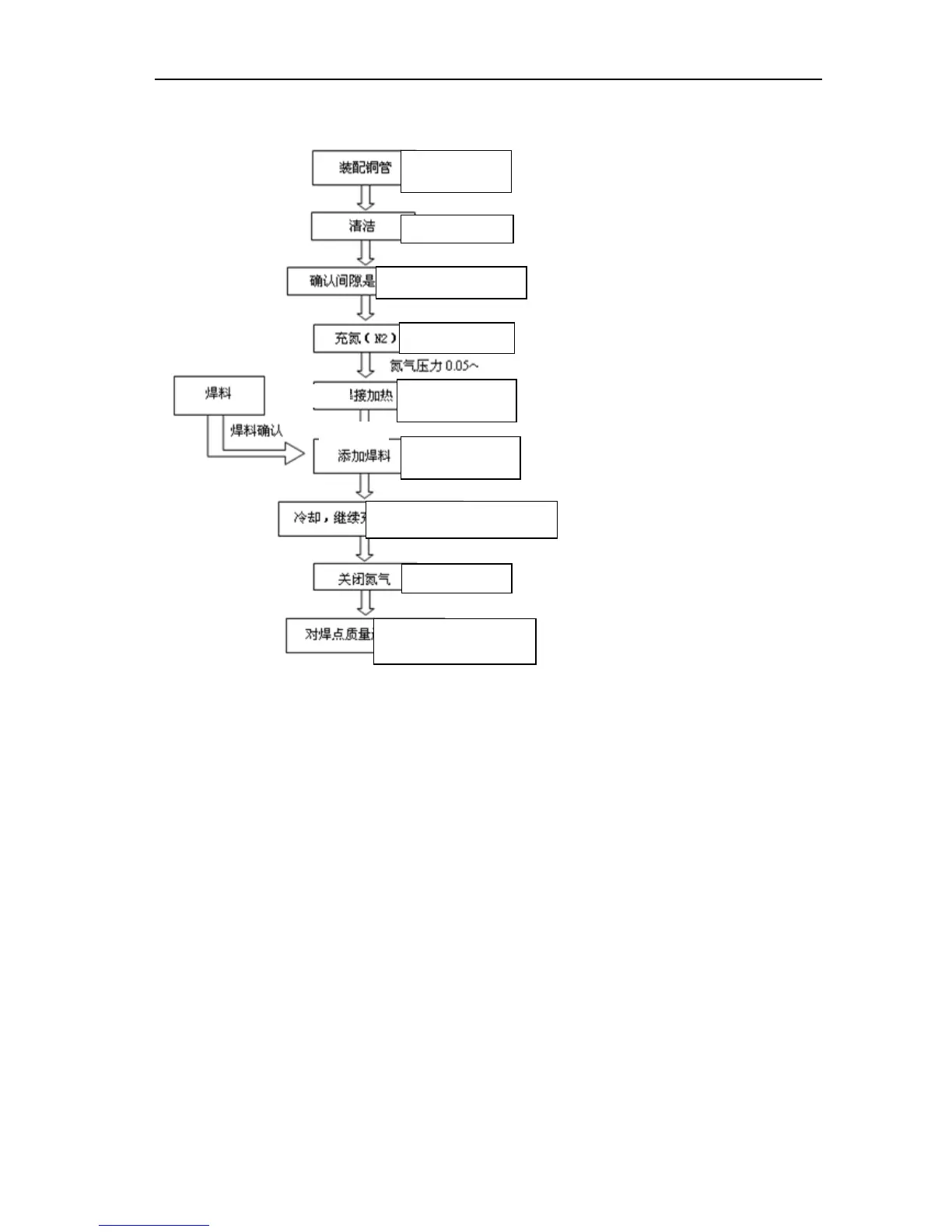

4)Operation order

Basic procedures for welding:

a. Cleaning of portions for braze welding

Polishing……………………Removing metal materials at connection portion. (Removing oxidation

film using non-woven fabric, abrasive cloth or abrasive paper)

Ungrease……………………If any oil stain is existent, acetone or spirit solvent shall be used for

ungrease treatment.

At the same time, compressed air at 0.8MPa (gauge pressure) shall be used for cleaning. The

cleaning shall be repeated not less than 3 times, until there is no dirt discharged.

b. Check whether clearance between pipe and connector is proper.

Put the connector into the pipe and face downward. If the connector does not fall down depending

on friction force, the clearance is considered proper.

c. Nitrogen-filled protection

● Since vigorous oxidation would occur on the surface of copper pipe at braze welding

temperature, to effectively restrain the generation of oxide coating in copper pipe, nitrogen-filled

protection for copper pipe is necessary.

● After copper pipes are assembled, nitrogen shall be filled in copper pipe connectors.

●

Method for charging nitrogen into copper pipe

Nitrogen charging method:

Pressure is 0.05~0.3MPa. Nitrogen flow of 4~6L/min (gas flow can be sensed by hand) shall be

guaranteed to charge in work pieces.

Assemble copper

pipes

Cleaning

Check whether clearance

is proper.

Fill nitrogen N2

Nitrogen pressure 0.05-0.3Mpa 0.5±0.1kgf/cm

2

Welding flux

Acknowledge

welding flux

Add welding flux

Cooling, continue to fill nitrogen

for over 10s

Shut off nitrogen

Welding heating

Make visual inspection to

the weld quality

Loading...

Loading...