GREE DC INVERTER HEAT PUMP CONDENSING UNIT

66

When the separator is detached, check whether there are impurities inside. Below is the checking method:

NOTE:

When pouring the liquid from the separator, make sure the discharge pipe is at the lower position.Slant at an

angle not larger than 20°

Use a transparent container to collect the content inside the separator. Check its color, seal it well and return

it to the factory for inspection.

NOTE:

If the compressor is damaged and needs to be replaced, the gas-liquid separator should also be replaced,

whether or not there are impurities in the separator or other abnormal conditions.

Confirm which parts of the system should be replaced. Make sure the pipe mouths of the damaged parts or

components are sealed by adhesive tape as soon as they are detached. Keep them in the original condition for

future analysis.

Step 7: Clear the pipeline

After confirming which parts of the system should be replaced, check the pipeline of the system. Blow

through the main pipeline with nitrogen. After clearing the pipeline, if the components are not replaced

immediately, seal the pipeline with adhesive tape to prevent the system from being contaminated by water and

impurities in the air.

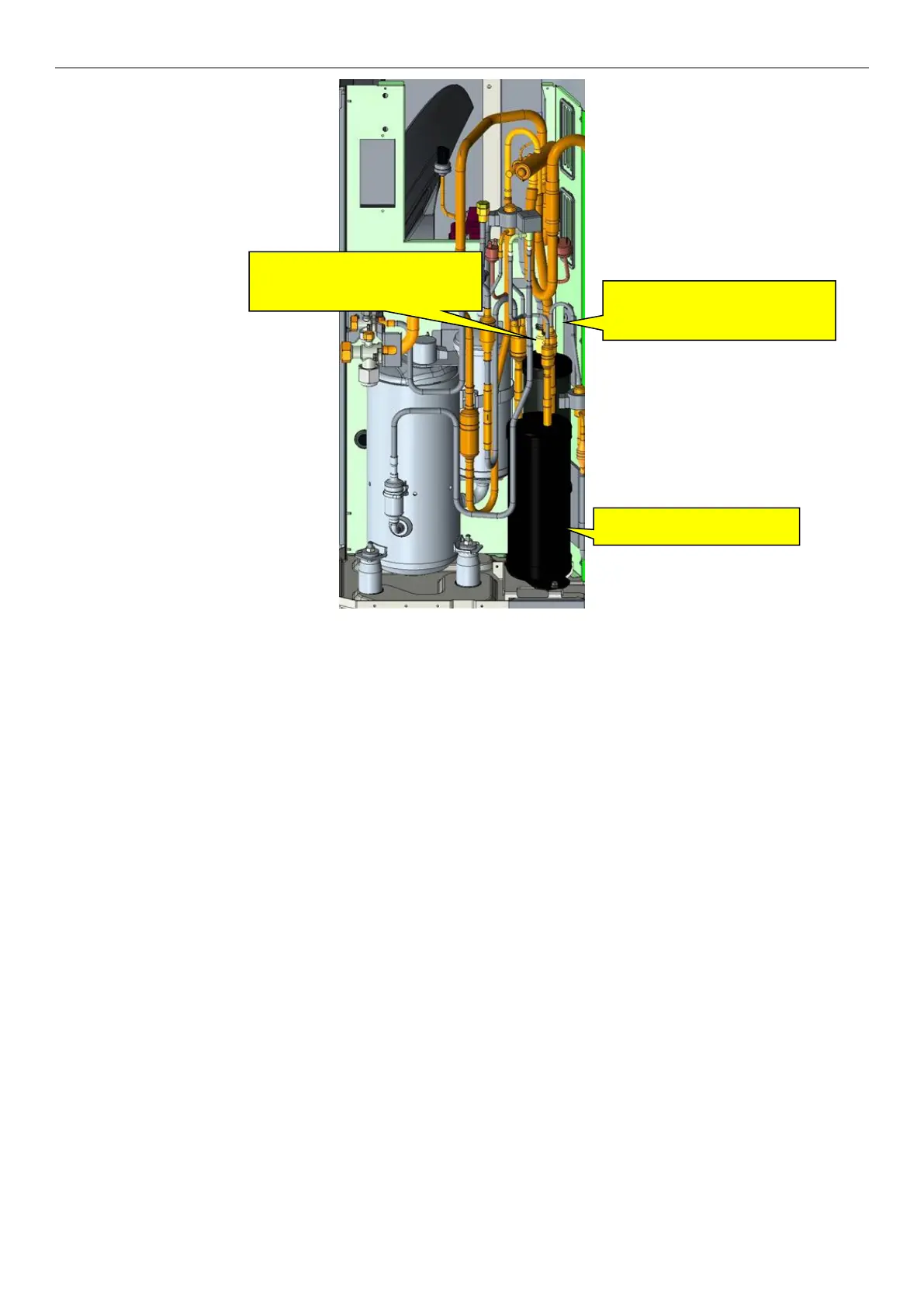

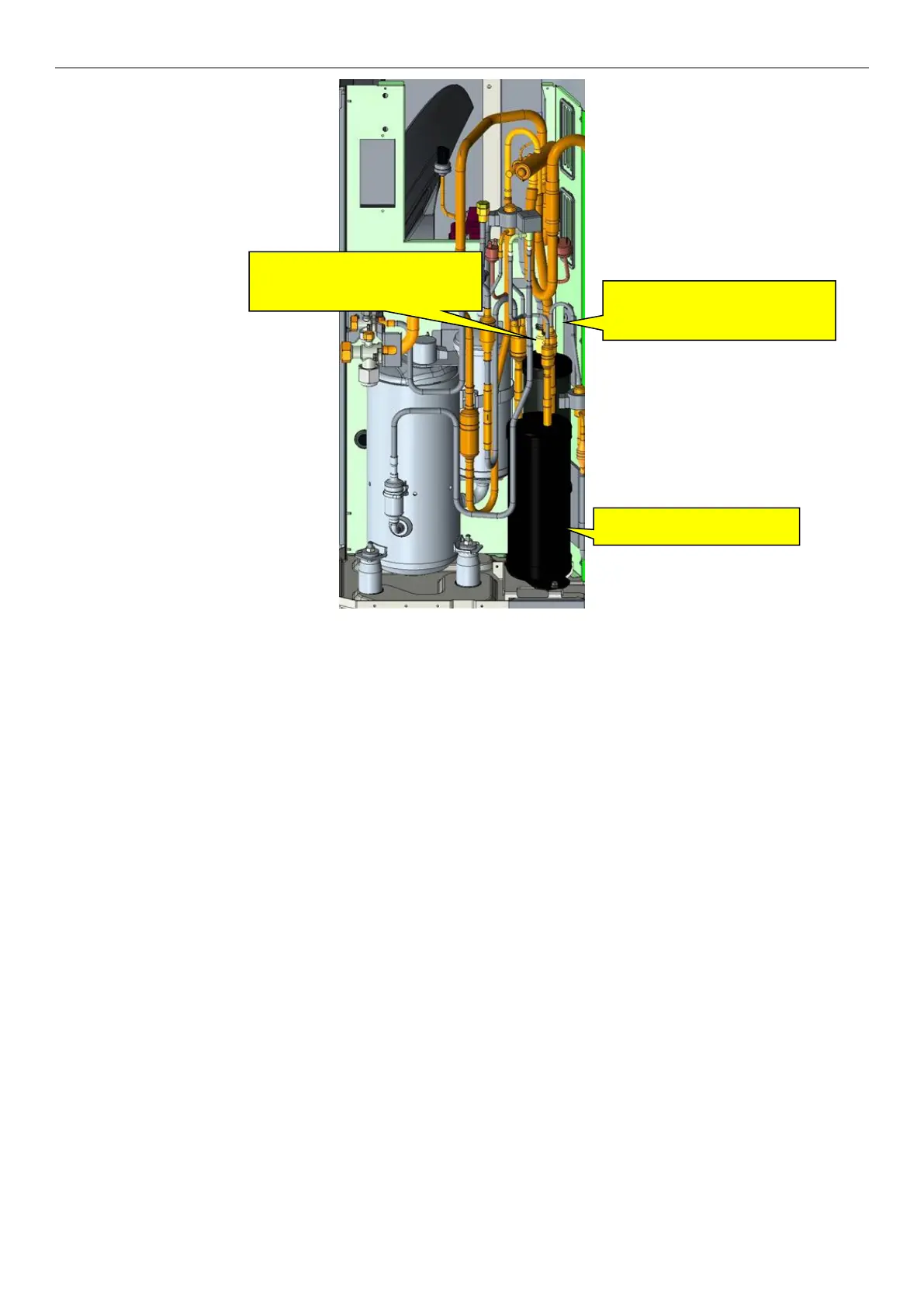

2. Remove the screw bolt of

the separator.

1. Remove the screw bolt of

the separator.

Loading...

Loading...