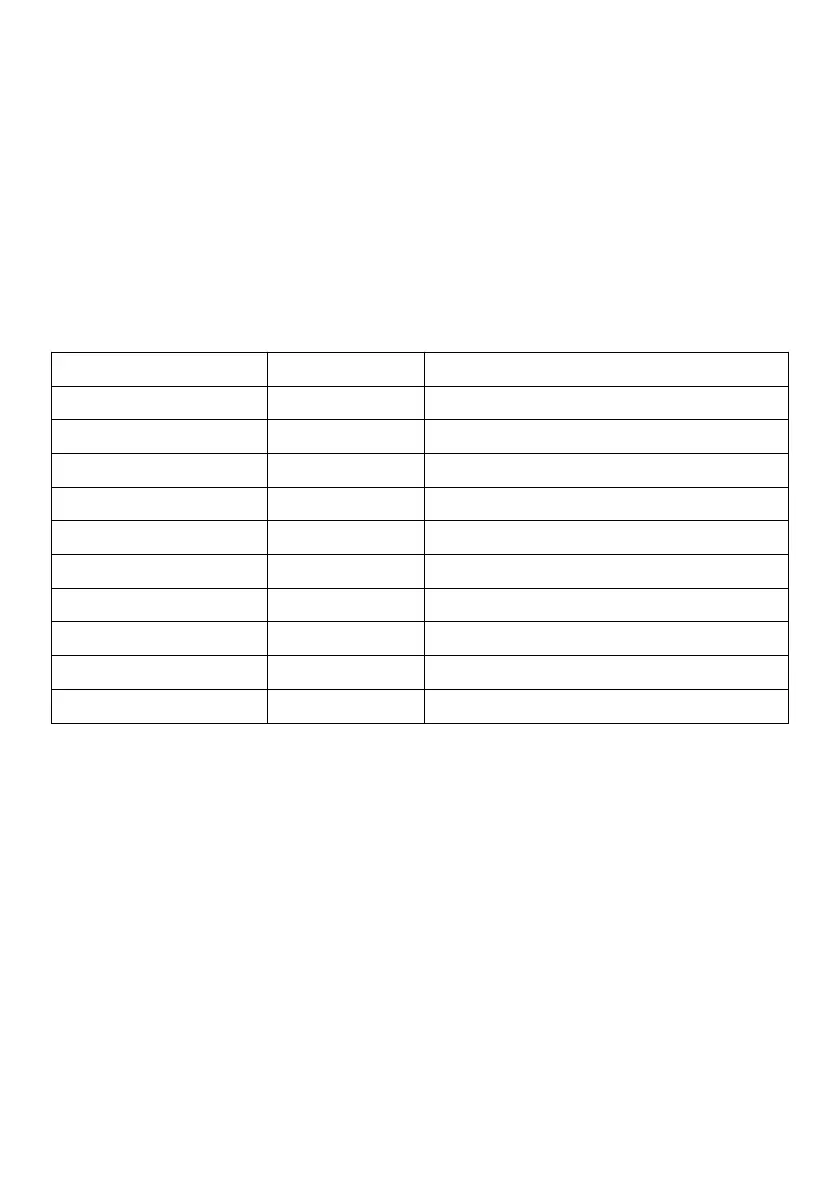

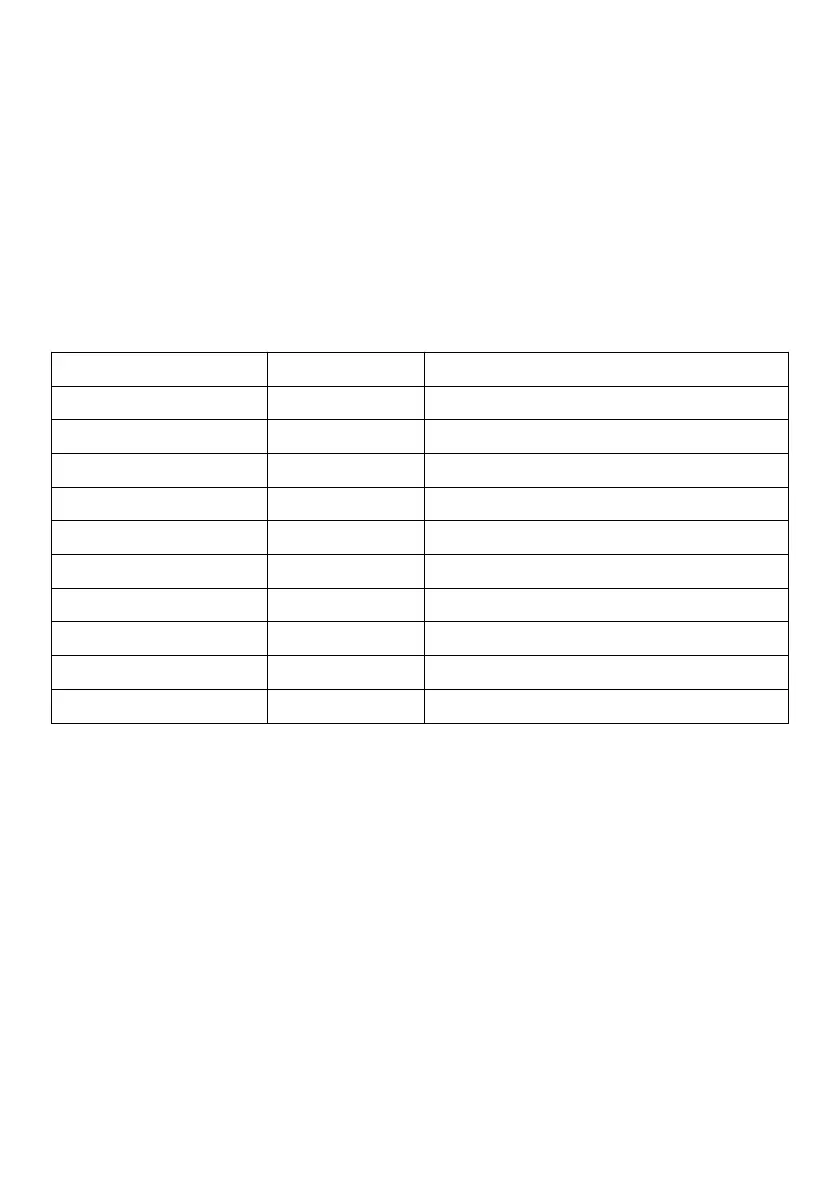

12. Preventive Maintenance

For safe operation of the charger and to ensure a continuous and adequate level of service

for users, regular maintenance and control of the equipment is required.

In addition to these regular maintenance operations, in case a fault or suspected fault, a

corrective maintenance operation must be performed.

Below is the recommended preventive maintenance plan. If the operating environment is

harsh (such as sandy environment, dusty environment, etc.), please shorten the

maintenance cycle as appropriate.

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Check and repair/replace if damaged

Accident handling

Catastrophic accidents include charging equipment failures caused by lightning strikes,

flooding, earthquakes, fires and other disasters. For disasters that may seriously affect

safety, prevention should be the priority. At the same time, the charging station should

have countermeasures and corresponding manpower and material resources to deal with

these disasters, and should have emergency management regulations and major accident

repair procedures.

It is recommended that when there is water immersion near the charging device, all

switches inside the charging station should be disconnected, and the upstream power

supply switch of the charging station should be disconnected to ensure the safety of

personnel and prevent electric shock. The power module can be pulled out to minimize

losses.

Loading...

Loading...