Model G0725 (Mfd. Since 03/18)

-27-

Previously Surface

Planed Face

3. Edge Joint on the Jointer—The concave

edge of the workpiece is jointed flat with the

jointer.

4. Rip Cut on a Table Saw—The jointed edge

of the workpiece is placed against a table saw

fence and the opposite edge cut off.

Squaring stock involves four steps performed

in the order below:

1. Surface Plane on the Jointer—The concave

face of the workpiece is surface planed flat with

the jointer.

2. Surface Plane on a Thickness Planer—The

opposite face of the workpiece is surface planed

flat with a thickness planer.

Squaring Stock

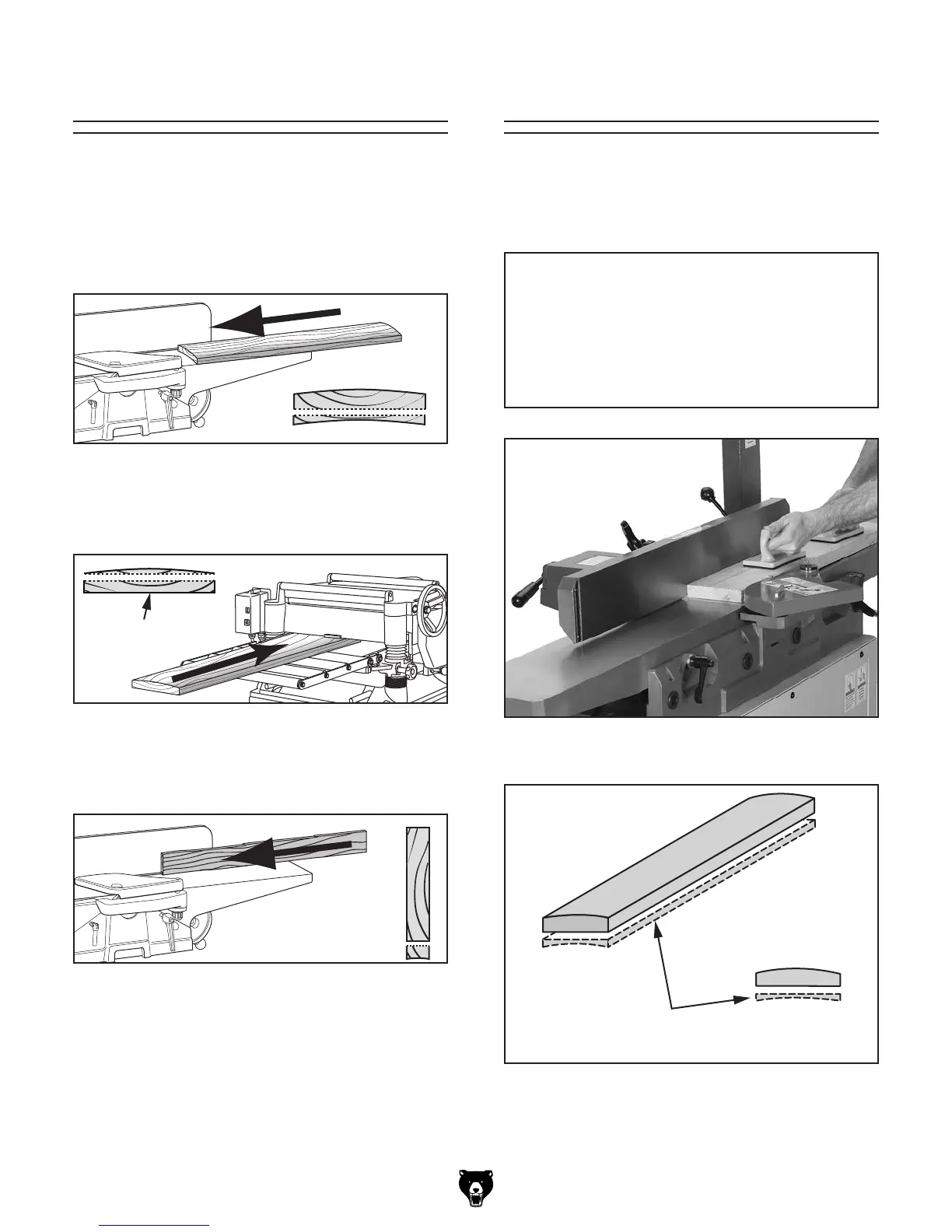

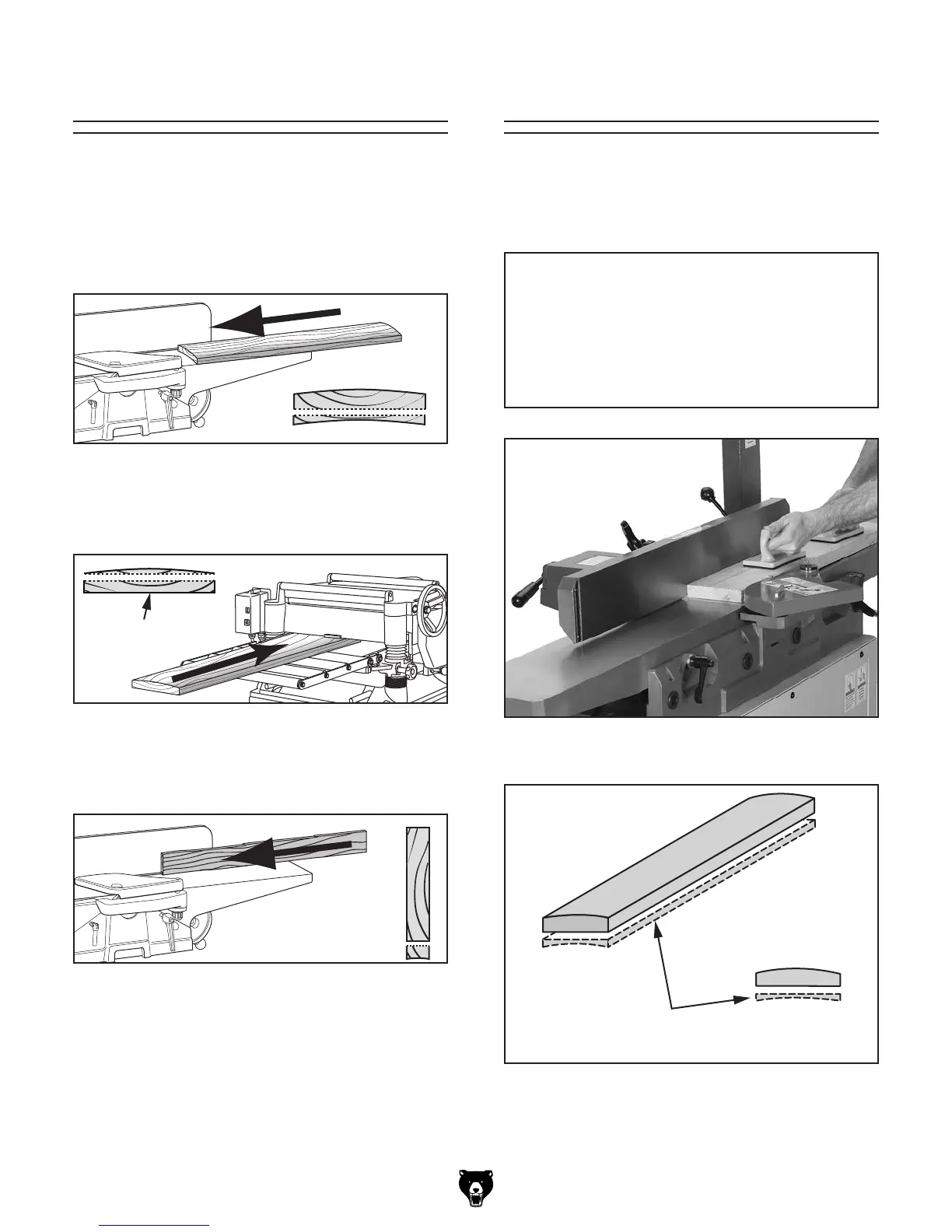

The purpose of surface planing on the jointer

is to make one flat face on the workpiece (see

Figures 35–36) to prepare it for surface planing

on a thickness planer.

Figure 36. Illustration of surface planing results.

Figure 35. Example photo of a typical surface

planing operation.

Surface Planing

NOTICE

If you are not experienced with a jointer,

set the depth of cut to zero and practice

feeding the workpiece across the tables as

described. This procedure will better pre-

pare you for the actual operation.

Loading...

Loading...