Model G0803Z (Mfd. Since 12/18)

-41-

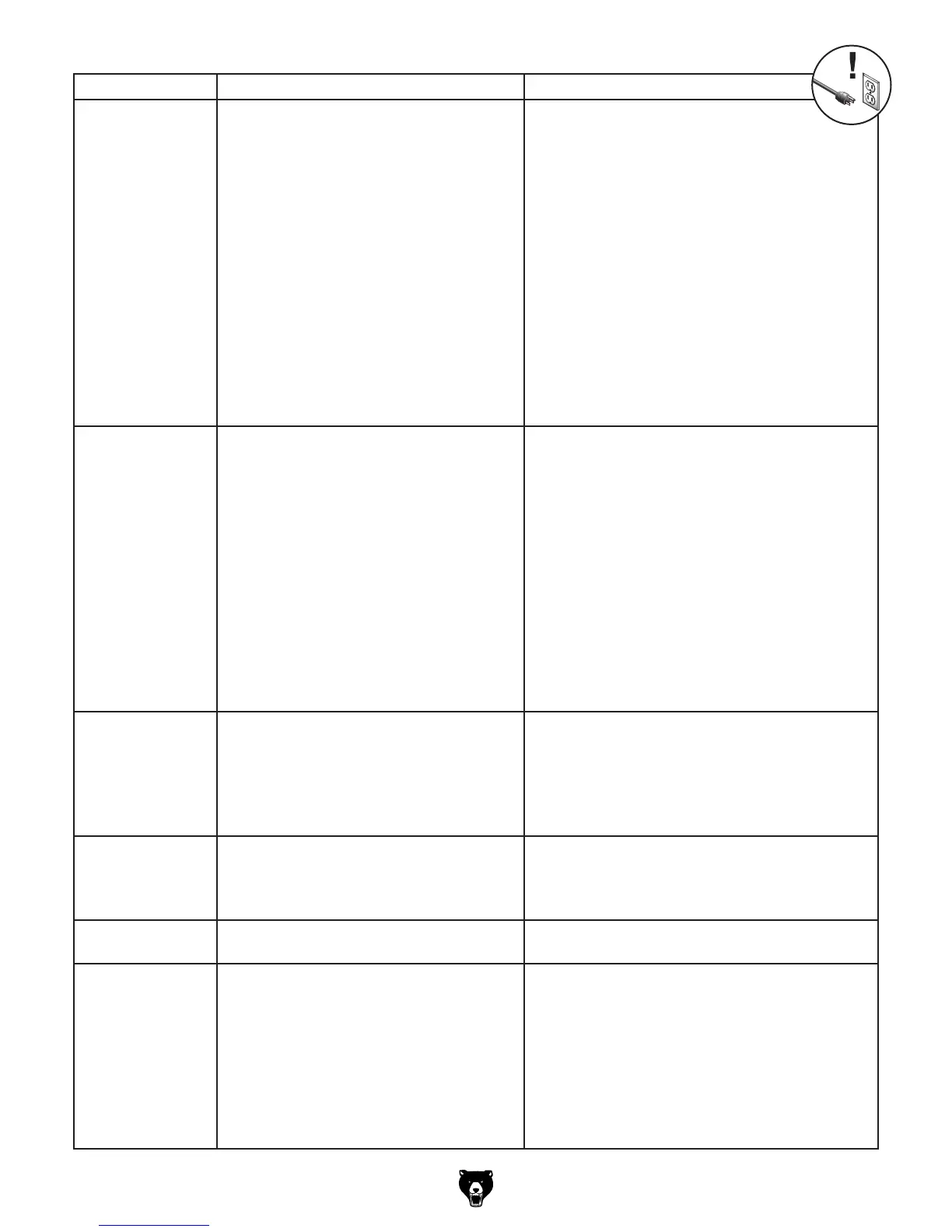

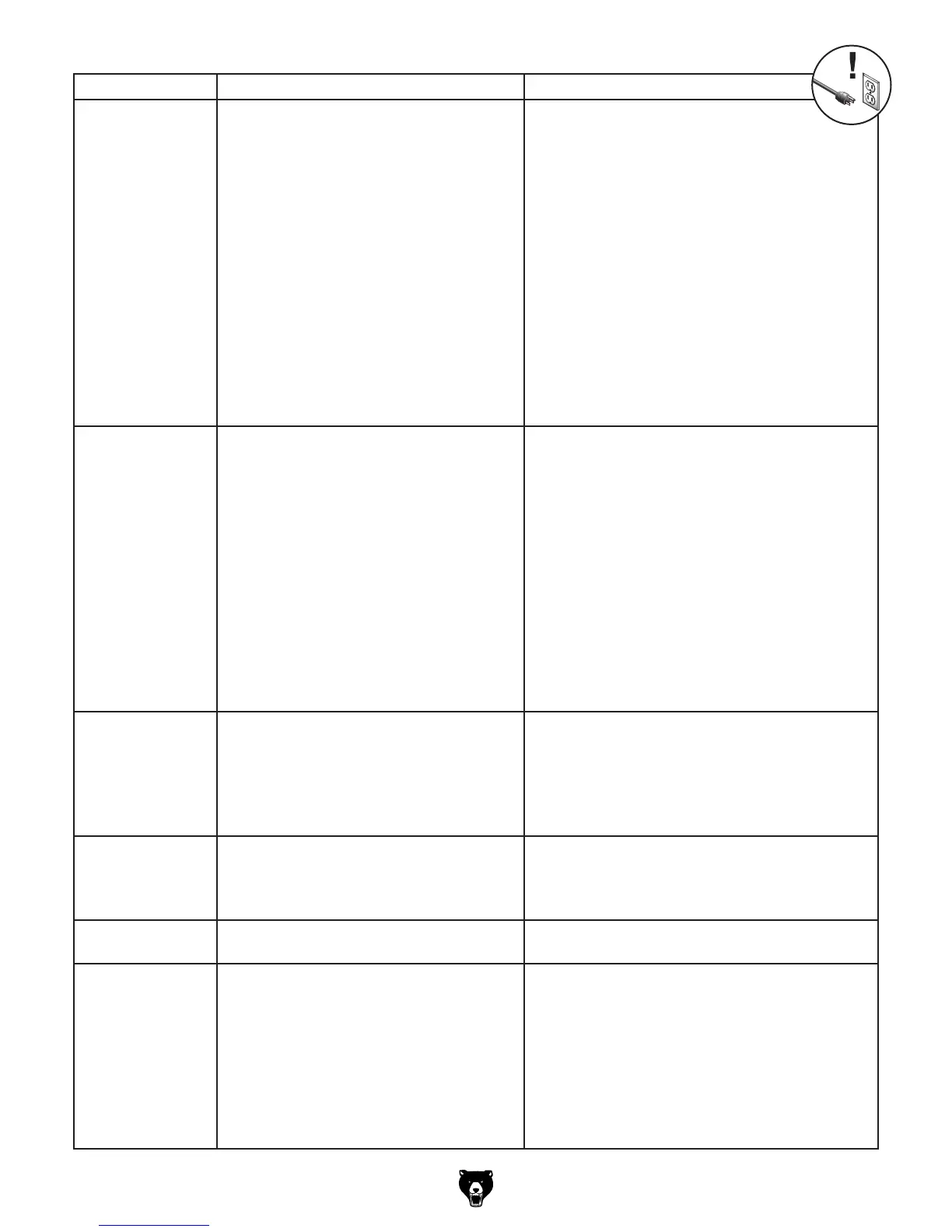

Symptom Possible Cause Possible Solution

Blade or teeth break/

crack.

1. Blade tension incorrect.

2. Blade incorrect for application.

3. Excessive feed rate/pressure.

4. Cutting corners too sharply.

5. Blade dull.

6. Blade tracking wrong.

7. Blade guides adjusted too far forward.

8. Blade guide height in wrong position.

9. Blade weld at fault.

10. Wheel tires worn or incorrectly installed.

11. Fence or miter slot out of alignment with

blade.

12. Bad bearings on wheels or guide bearings.

1. Adjust blade tension (Page 21).

2. Use correct blade for application.

3. Reduce feed rate/pressure.

4. Use a wider arc on outside cuts, or use relief cuts

to make tight inside cuts.

5. Replace blade (Page 32).

6. Adjust blade tracking (Page 17).

7. Adjust blade guides for correct blade support

(Pages 22–23).

8. Adjust upper blade guide so blade is as close to

workpiece as possible (Pages 22–23).

9. Replace blade (Page 32).

10. Replace or re-install tire.

11. Align table and fence with blade (Pages 25–26).

12. Replace wheels and/or guide bearings.

Blade slows,

smokes, shows

overheating or wears

on one side.

1. Too much side pressure when feeding

workpiece.

2. Blade contacting table insert.

3. Blade guides worn or misadjusted.

4. Blade has insufficient support.

5. Blade installed backwards or inside out.

6. Wheels out of alignment.

7. Dull or incorrect blade.

8. Blade is bell-mouthed.

9. Fence not parallel with blade.

1. Feed workpiece straight into blade.

2. Adjust blade guide bearings to eliminate excess

side pressure (Pages 22–23).

3. Adjust blade guide bracket.

4. Adjust blade guides as close to workpiece as

possible (Pages 22–23).

5. Check blade installation; make sure teeth face front

of machine and point down in table throat. Re-

install blade if necessary (Page 32).

6. Adjust wheels so they are coplanar (Page 45).

7. Replace blade (Page 32).

8. Replace blade (Page 32).

9. Adjust fence parallelism with blade (Page 26).

Finished workpieces

are rough or show

scoring.

1. Blade overloaded and twists while cutting.

2. Blade TPI too coarse.

3. Blade loose and fluttering.

4. Blade tracking incorrect.

5. Blade has missing or bent teeth.

6. Blade has a faulty weld.

1. Decrease feed rate.

2. Use correct blade for material and type of cut.

3. Increase blade tension as required (Page 21).

4. Adjust blade tracking (Page 17).

5. Replace blade (Page 32).

6. Replace blade (Page 32).

Table is hard to tilt.

1. Table tilt lock lever tightened.

2. Sawdust or pitch trapped between trunnion

and base.

3. Metal burrs on trunnion.

1. Loosen table tilt lock lever.

2. Remove sawdust or pitch.

3. Remove burrs.

Miter bar binds in

miter slot.

1. Miter slot dirty or gummed up.

2. Miter bar bent.

1. Carefully clean miter slot.

2. Replace.

Blade tracks

incorrectly, or comes

off wheels.

1. Tracking is not adjusted properly.

2. Wheels are not coplanar.

3. Blade tension too loose.

4. Blade guides too tight against blade.

5. Feeding workpiece too fast.

6. Incorrect blade for bandsaw.

7. Blade is bell-mouthed, worn, or dull.

8. Wheel tire damaged or worn.

1. Adjust tracking (Page 17).

2. Adjust wheel coplanarity (Page 45).

3. Increase blade tension (Page 21).

4. Adjust blade guides (Pages 22–23).

5. Feed workpiece slower.

6. Install correct blade.

7. Install new blade (Page 32) and remove tension

from blade when not in use.

8. Replace wheel tires.

Loading...

Loading...