Model G0803Z (Mfd. Since 12/18)

-47-

To adjust lower wheel laterally:

1.

DISCONNECT MACHINE FROM POWER!

2.

Remove fence and table from machine.

3.

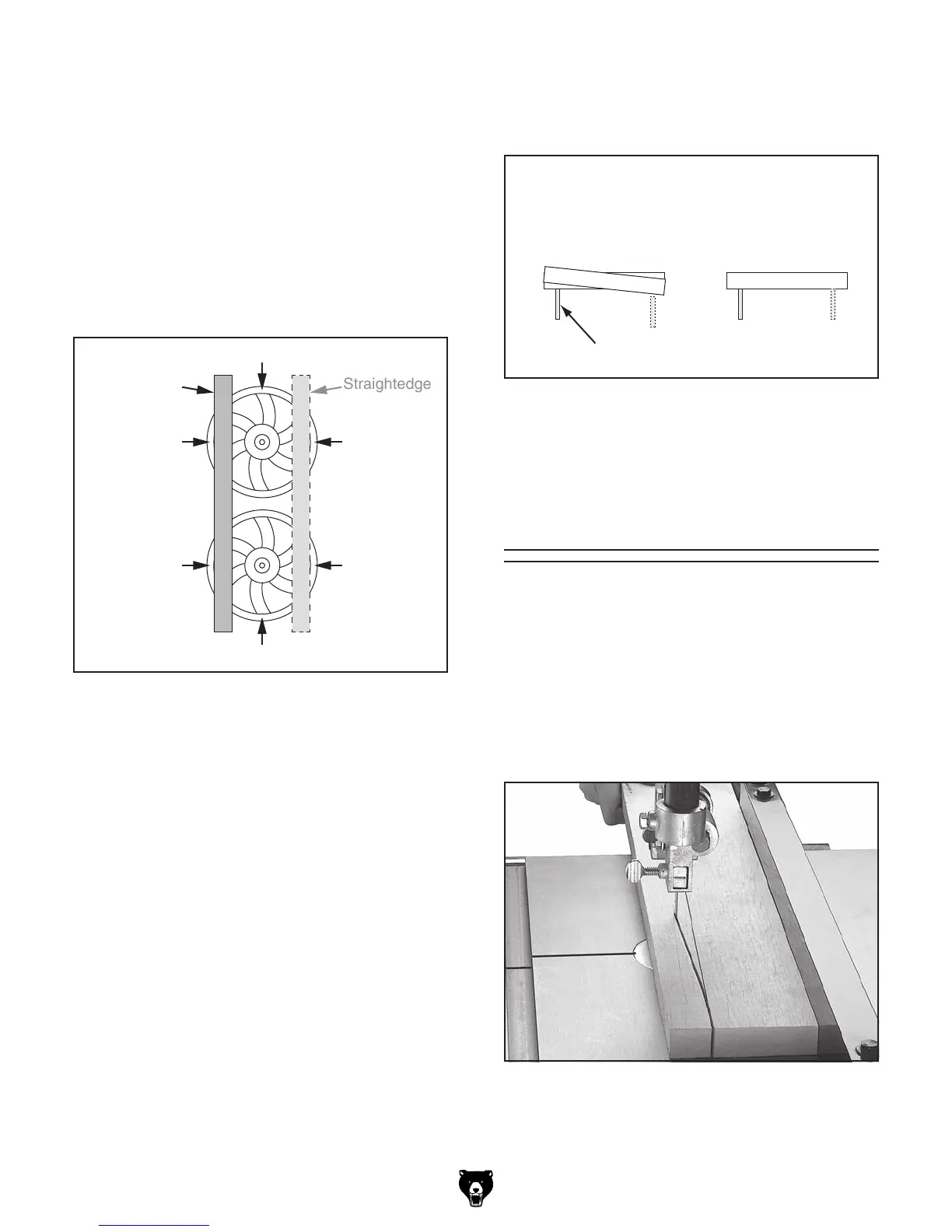

Check wheels at A and B locations (see

Figure 58). The wheels should align.

— If the wheels do not align, they require lat-

eral adjustment (see Figure 59); proceed

to Step 4.

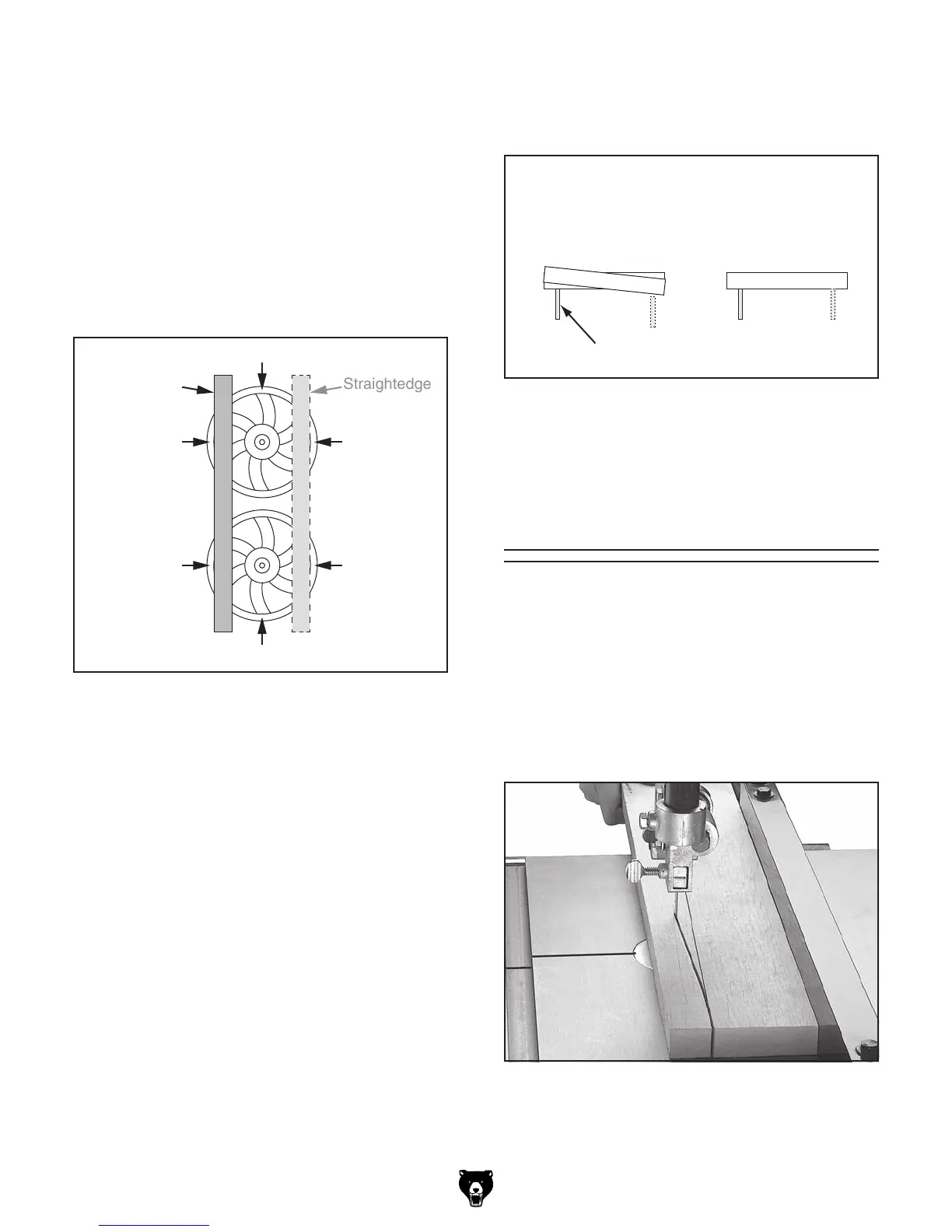

Requires lateral

adjustment

Viewed From Above

After lateral

adjustment

Straightedge

Figure 59. Before and after lateral wheel

alignment (viewed from above).

7. Re-tighten hex nuts loosened in Step 6.

B2 A2

A1 B1

Upper Wheel

Lower Wheel

Straightedge

Figure 58. Example of using a straightedge to

check lateral wheel alignment.

4.

Mark upper and lower wheels with a pencil or

marker to indicate measuring locations (see

Figure 58).

Note: Marking the wheels ensures more

accurate results in case there are irregulari-

ties in the wheels.

5.

Loosen hex nuts on rear left and right adjust-

ment bolts (see Figure 57 on Page 46).

6.

Rotate left and right adjustment bolts until

lower wheel is coplanar with upper wheel,

see Figure 59.

Blade Lead

Bandsaw blades may wander off the cut line when

sawing, as shown in Figure 60. This is called

blade lead.

Blade lead is usually caused by too fast of a

feed rate, a dull or abused blade, or improper

blade tension. If your blade is sharp/undamaged,

properly tensioned, and you still have blade lead,

perform the following procedures.

Figure 60. Example of blade lead.

6.

Rotate left and right adjustment bolts until

lower wheel is coplanar with upper wheel,

see Figure 59.

Item(s) Needed Qty

Hex Wrench 4mm. ............................................. 1

Loading...

Loading...