Model G0803Z (Mfd. Since 12/18)

-45-

Wheel Alignment

Wheel alignment is important for optimal perfor-

mance from your bandsaw. Wheels are properly

aligned when they are parallel with each other and

in the same plane or “coplanar” (see the illustra-

tion in the figure to the right).

When wheels are coplanar, the bandsaw is

more likely to cut straight without wandering; and

vibration, heat, and blade wear are considerably

decreased because the blade is automatically bal-

anced on the wheel.

Bringing the wheel into alignment may require a

combination of shimming a wheel and adjusting

the position of the lower wheel shaft.

Item(s) Needed Qty

Precision Straightedge 3'. .................................. 1

Fine Ruler

.......................................................... 1

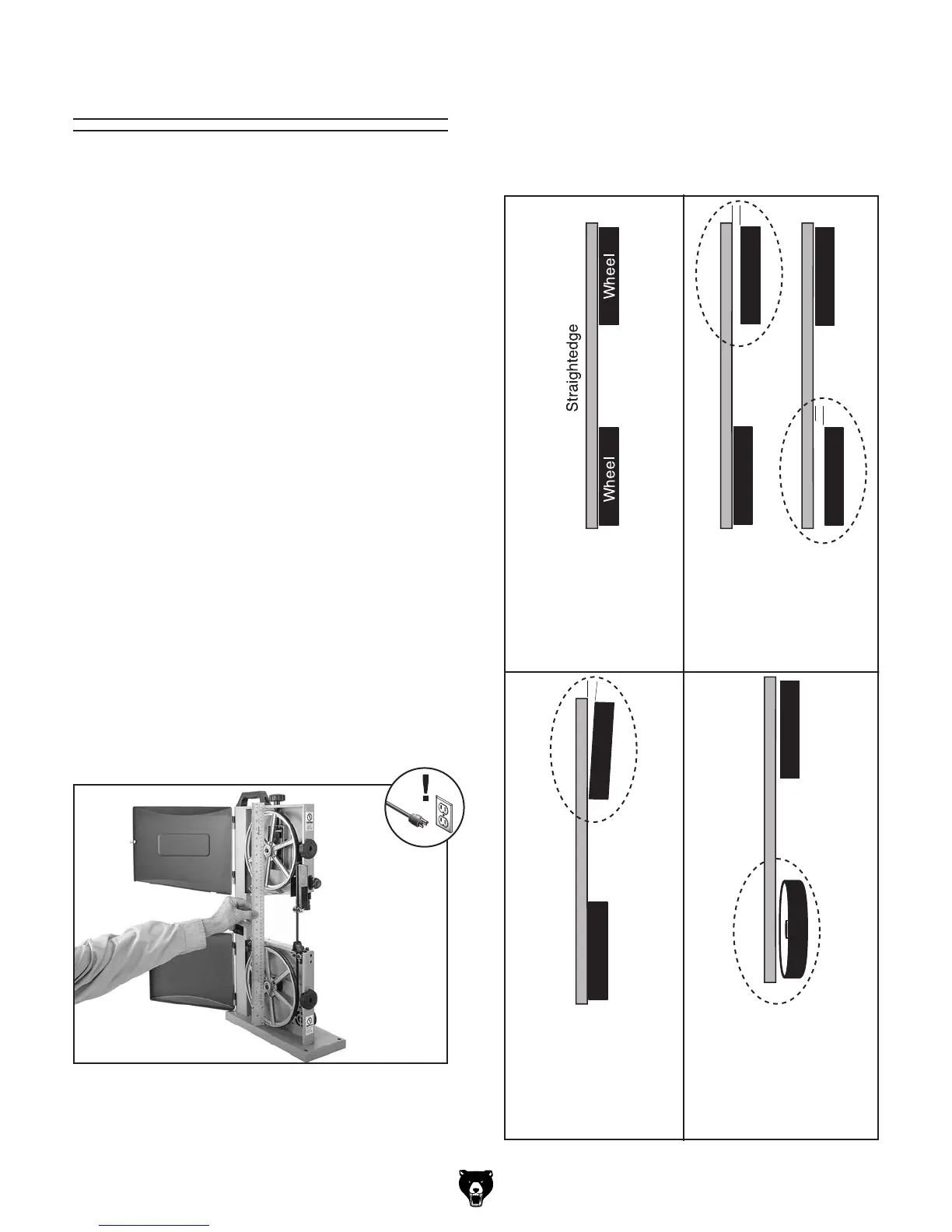

Figure 54. Example of checking if wheels are

coplanar.

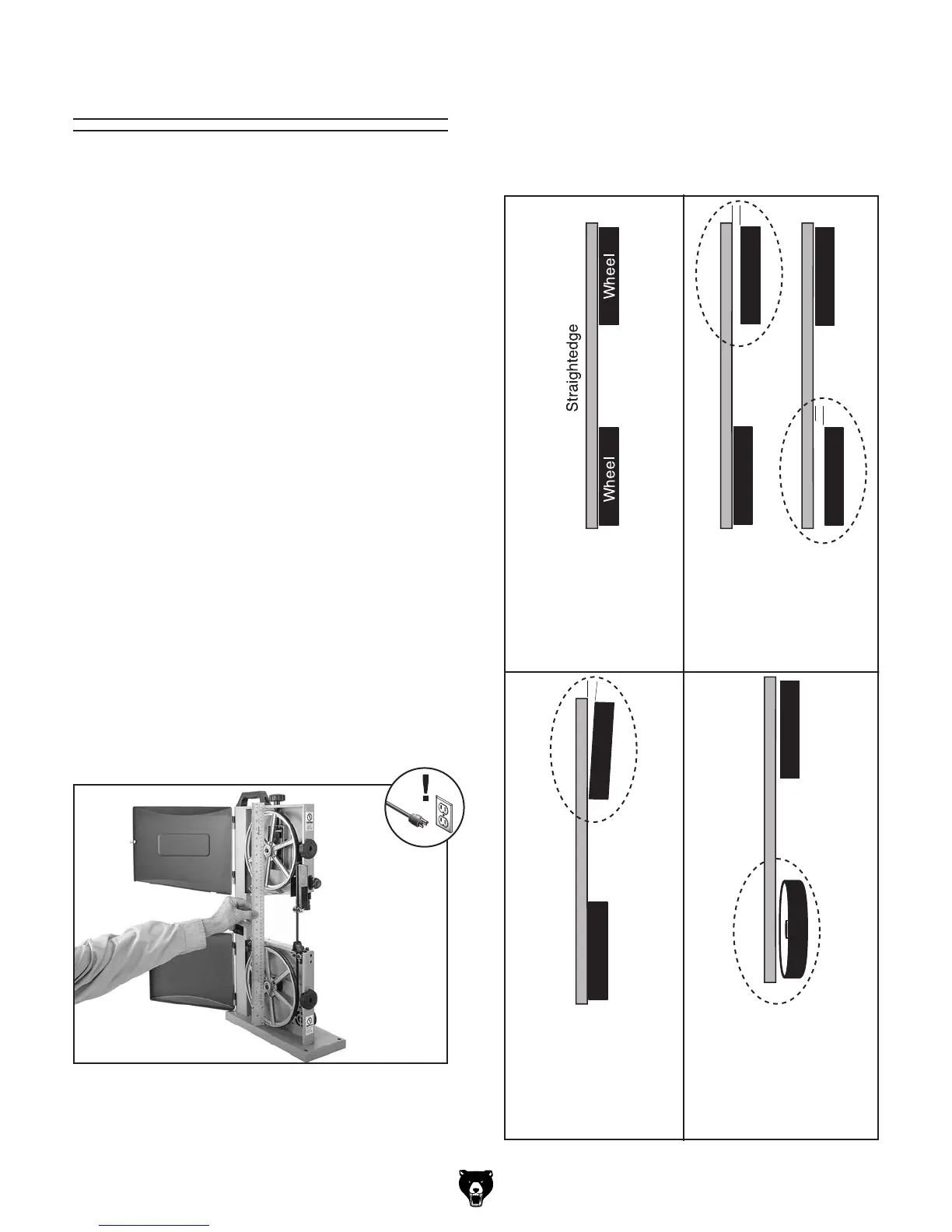

Figure 55. Wheel alignment illustration.

or

Wheels parallel and

aligned: No adjust-

ment needed.

Wheels parallel, but

upper or lower wheel

is not coplanar with the

other wheel: Move the

upper wheel in or out.

Upper wheel is not

vertically aligned with

lower wheel: Use

blade tracking knob

to tilt upper wheel.

Lower wheel is not

laterally aligned with

upper wheel: Adjust

rear adjustment set

bolts to tilt lower wheel

left/right.

4.

Check wheel alignment, and adjust tracking

knob to bring both wheels into alignment as

much as possible. If wheels cannot be adjust-

ed coplanar, use Figure 55 to determine how

to proceed with alignment adjustments.

1. DISCONNECT MACHINE FROM POWER!

2.

Remove table.

3. With blade on and properly tensioned,

hold a straightedge close to center of both

wheels. Make sure straightedge fully extends

across the rims of both wheels, as shown in

Figure 54.

Checking Wheel Alignment

Loading...

Loading...