DA98D User Manual

36

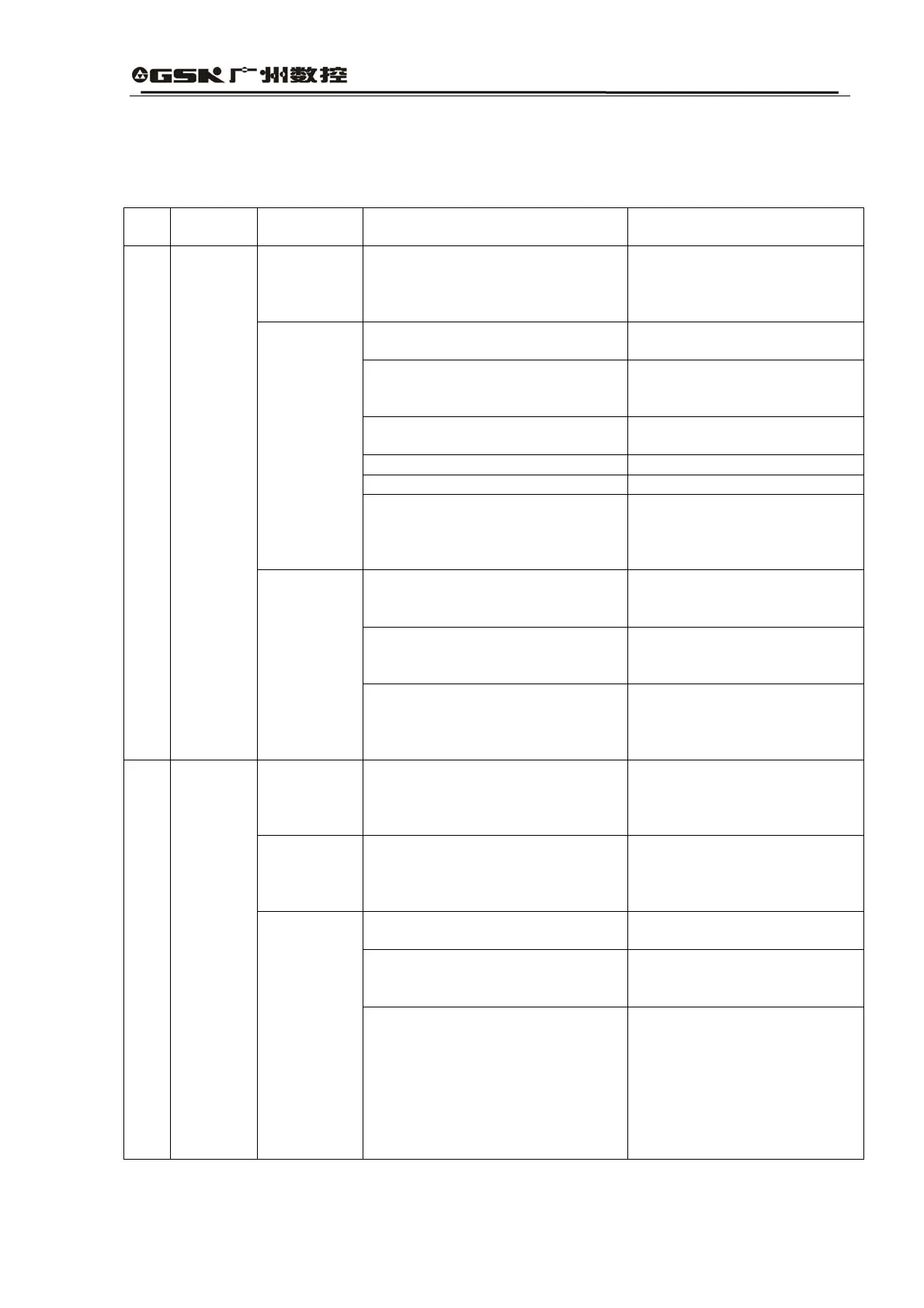

5.2 Methods for Handling Alarms

Table 5.2 Methods for Handling Alarms

Alarm

Code

Alarm

Name

Operation

State

Reasons Handling Methods

Occur when

switching on

the control

power

①Failure in control power board

②Encoder failure

①Replace servo driver.

②Replace servo motor.

Excessively high input command

pulse frequency.

Correctly set the input

command pulse.

Excessively small acceleration/

deceleration time constant results

in overshoot.

Increase

acceleration/deceleration tim

constant.

The input electronic gear ratio is

excessively high.

Correctly set the ratio.

Encoder failure. Replace servo motor.

Bad encoder cable. Replace encoder cable.

Occur during

motor

operation

Instable servo system cause

overshoot.

①Reset related gains.

②If the gains cannot be set at

a proper value, reduce inertia

rate for load rotation

Excessively large load inertia.

①Reduce load inertia.

②Replace it with driver and

motor of greater frequency.

Zero-point error in encoder.

①Replace servo motor

②Contact the manufacturer

for readjusting the zero point.

1

Excessive

Speed

Occur

immediately

after the

motor is

started

①Wrong connection of motor lead

of U, V and W.

②Wrong connection of encode

cable leads

Correct wiring.

Occur when

switching on

control

power

Failure in circuit board. Replace servo drive unit.

Occur when

switching on

main power

supply

①Excessively high power voltage.

②Abnormal wave pattern of power

voltage.

Examine the power supply

source.

Disconnection of braking

resistance.

Rewiring.

①Braking transistor is damaged.

②Internal braking resistance is

damaged.

Replace servo drive unit.

2

Over-

voltage in

Main

Circuit

Occur during

motor

operation

Insufficient capacity in the braking

return circuit.

①Reduce start/stop frequency .

②Increase

acceleration/deceleration time

constant.

③Reduce torque limiting value.

④Reduce load inertia.

⑤Replace it with driver and

motor of greater frequency.

Loading...

Loading...