DA98D User Manual

54

Four Types of Internal Speeds

Acceleration/Decele

ration Function

Parameter setting for acceleration/deceleration time 1 ms ~

10000ms(0r/min←→1000r/min)

Monitoring

Function

Rotation rate, current position, command pulse accumulation, position error,

motor torque, motor current, linear velocity, absolute position of rotor, command

pulse frequency, operation state, input/output terminal signal and etc.

Protection Function Excessive speed, voltage shortage in main power supply, over-current,

overload, abnormal brake, abnormal encoder, abnormal control power, position

excess and etc.

Display and

Operation

6-phase LED nixie tube, 4 keys

Applicable load

inertia

Less than 5 times of motor inertia

Dimension 240 mm×177.5 mm×90mm(see figuration drawing)

8.2 Servo Motor Specifications

1) Product Introduction

GSK SJT series of three-phase AC permanent-magnet synchronous servo motors has the

following technical features:

◆ Adopt new rare-earth materials, with great output power.

◆ Good low-speed performance, with speed ratio>1:10000.

◆ High dielectric strength and insulation resistance for safe operation.

◆ Powerful overlaod capacity: torque can reach 8 times of rated torque in an instant.

2) Terminal Explanation

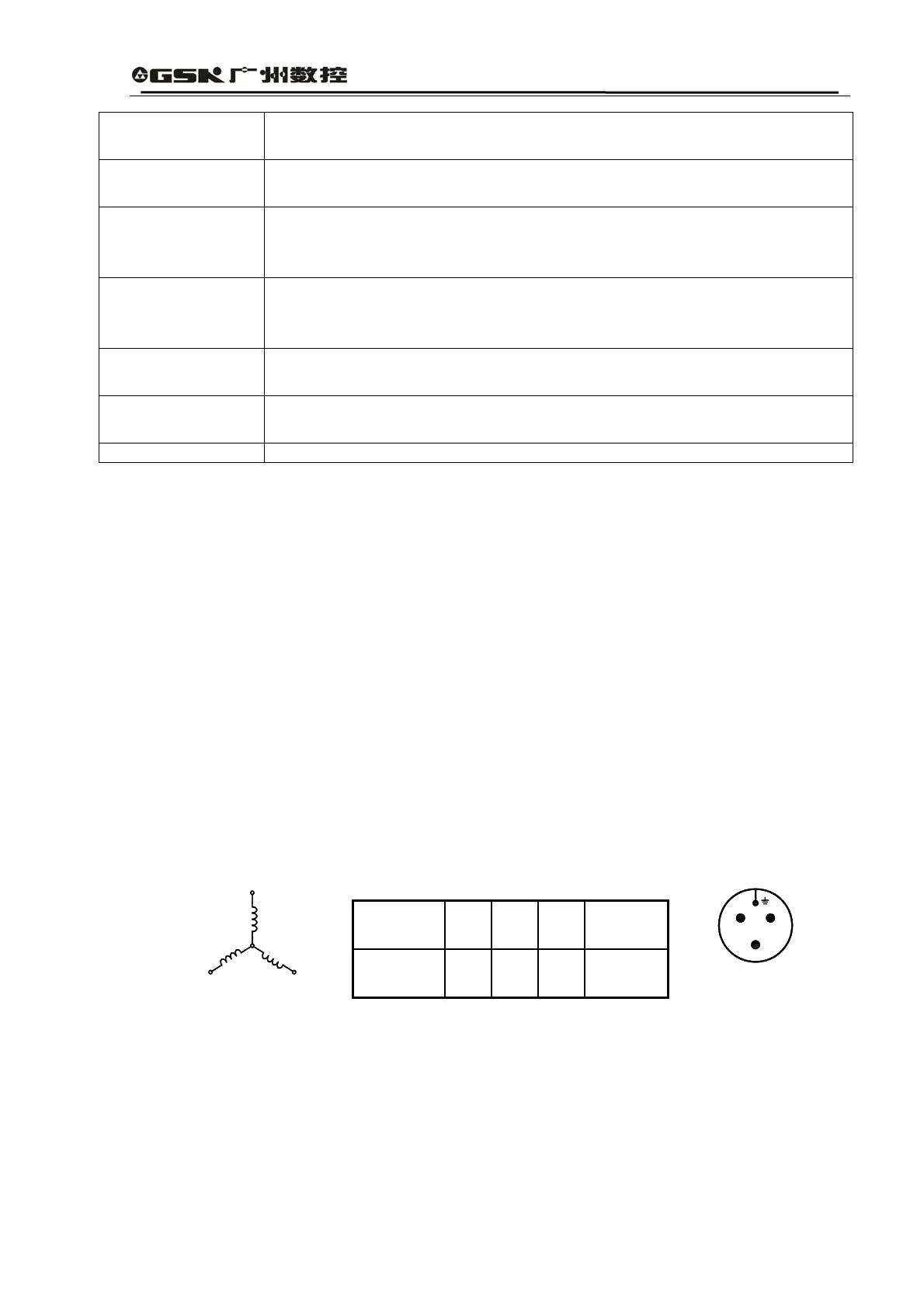

(1) SJT Series of Motor Winding

U,V,W,PE terminal.The three winding phases of U, V and W of motor and the rack earth

are led out through a 4-core connector. The corresponding relationships are shown in

Table 8.2. U, V, W and rack earth are respectively connected with terminal U, V, W and

PE of the main return circuit.

Table 8.2 Motor Wiring

The lead wires of photoelectric encoder are led out through a 15-core connector. The

corresponding relationships are shown in Table 8.2. The lead wires shall be connected

with plugs of the driver feedback signals CN2 according to driver requirements.

Motor

Lead Wire

U V W

Rack

(Earth)

Socket

No.

2 3 4 1

4

3

1

2

W V

U

Diagram for Plugs

wire weldin

area

Loading...

Loading...