DA98D User Manual

38

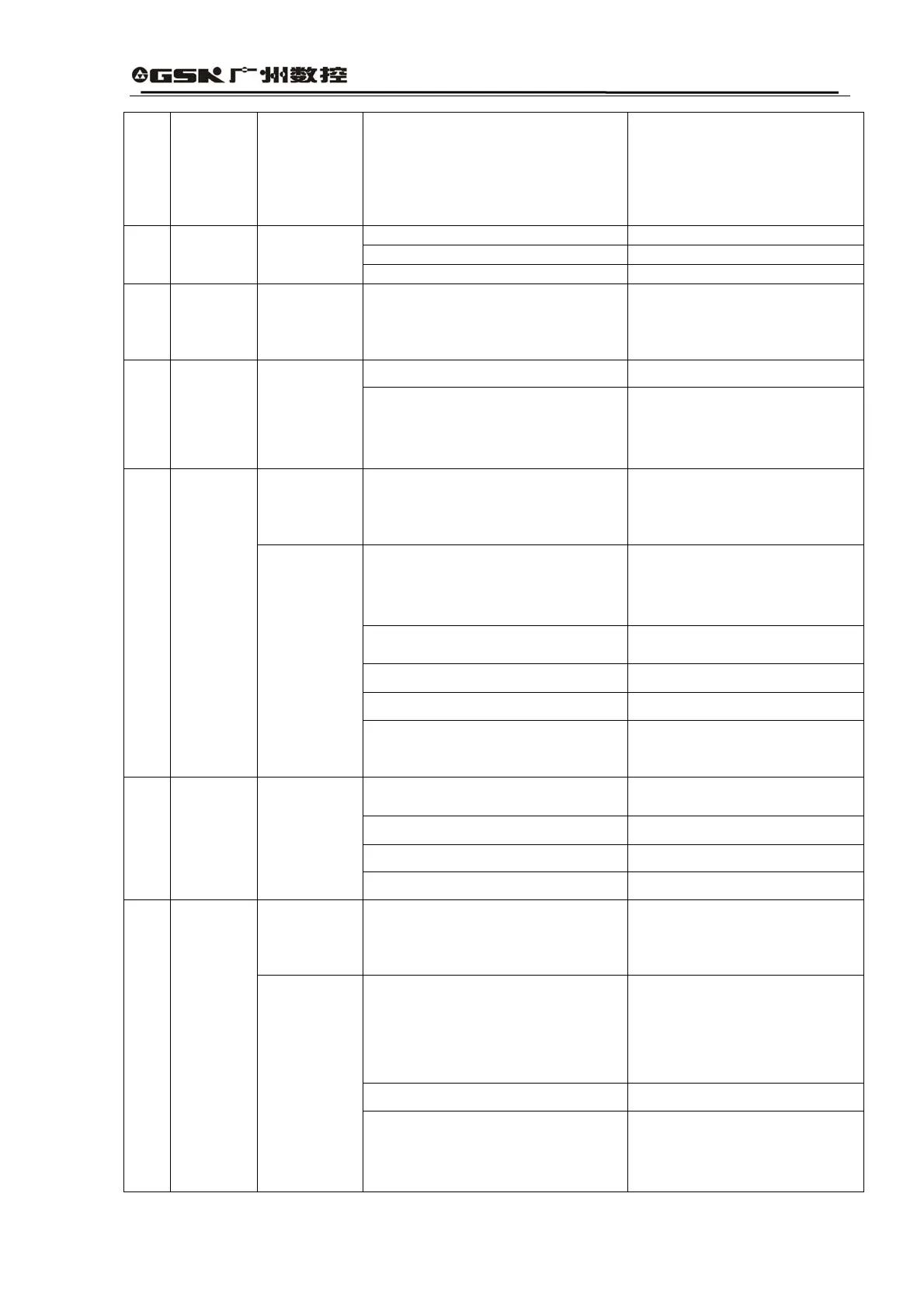

8

Overflow

of

Position

Error

Meter

The mot① or get stuck by the

machinery.

Abnormal input command pulse.②

Examine the machinery part ①

of the load.

②Examine command pulse.

.③ Examine whether the motor

works after receiving command

pulse

Wrong connection of encoder. Examine wire connection.

Damaged encoder. Replace motor.

9

Encoder

failure

Bad encoder cable. Replace cable.

9

Encoder

Failure

Excessively long encoder cable

results in low power voltage of

encoder.

Shorten cable.①

Supply power with multiple ②

core wires connected in

parallel.

Low input control power. Examine control power.

10

Voltage

Shortage

in Control

Power

①Internal connectors of driver

have bad performance.

Abnormal switch power.②

Damaged chip.③

Replace ① drive unit.

Examine connector.②

Examine switch power.③

Occur when

switching on

control

power

Failure in circuit board. Replace servo drive unit.

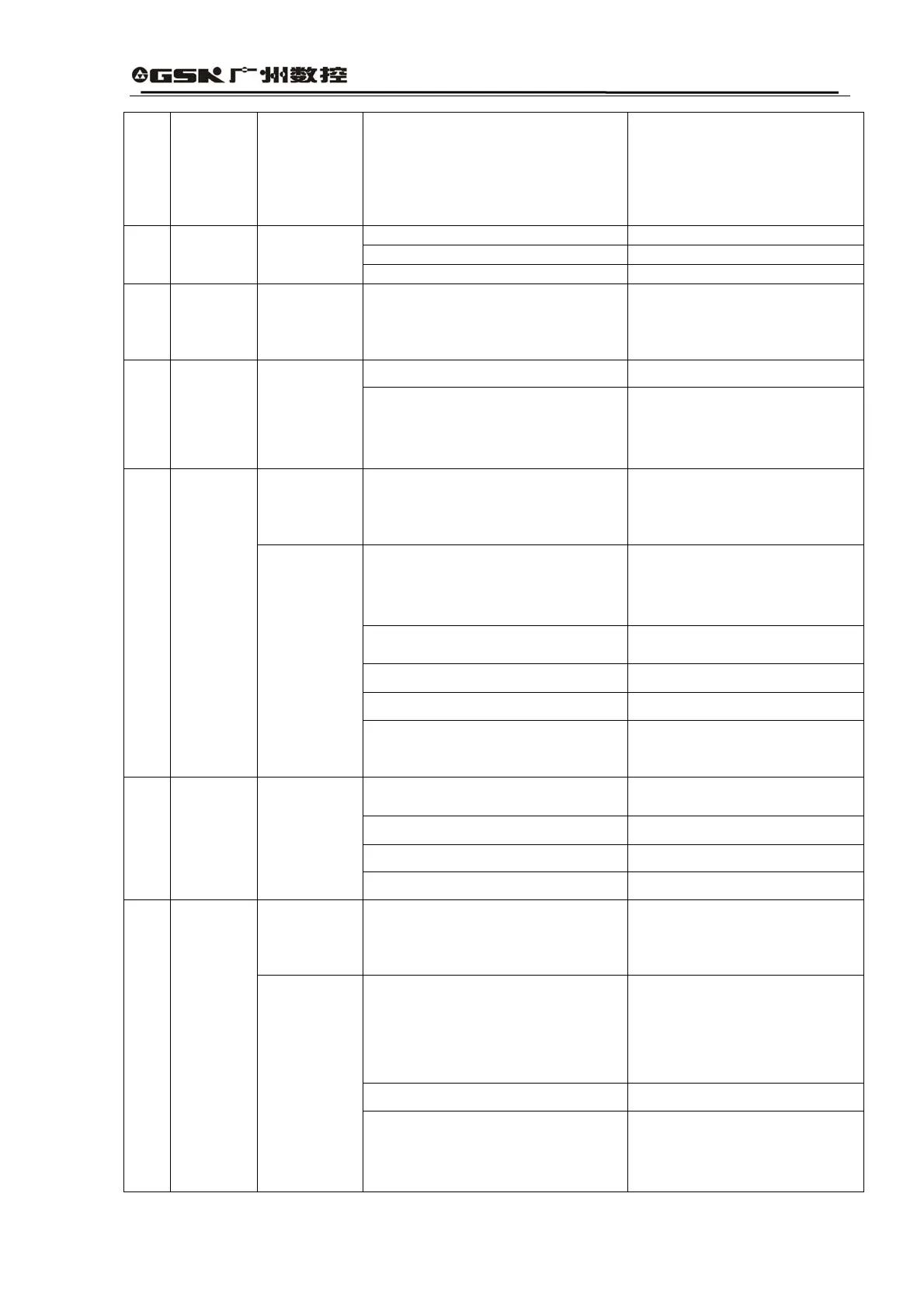

①Excessively low power voltage.

②Overheating.

Examine ① drive unit.

②Re-electrify.

③Replace drive unit.

Short circuit between motor leads

of U, V and W.

Examine wire connection.

Bad ground contact. Correct ground contact.

Damaged motor insulation. Replace motor.

11

Encoder

Failure

Occur during

motor

operation

Be jammed.

①Add circuit filter.

②Keep away from jamming

source

Short circuit between motor leads

of U, V and W.

Examine wire connection.

Bad ground contact. Correct ground contact.

Damaged motor insulation. Replace motor.

12

Excessive

Current

Damaged driver. Replace drive unit.

Occur when

switching on

control

power

Failure in circuit board. Replace servo drive unit.

Operation by exceeding rated

torque.

①Examine load.

②Reduce start/stop frequency.

Reduce torque limiting value.

Replace it with drive unit and

motor of greater frequency

Hold brake cannot be opened. Examine the hold brake.

13 Overload

Occur during

motor

operation

Instable motor with vibration.

①Increase gain.

②Increase

acceleration/deceleration time.

③reduce load inertia.

Loading...

Loading...