26

Operating manual

E1 - E2 - E3 GYS AUTO

Translation of the original

instructions

GAS FLOW CONTROL

In the main screen, a long press on button N°1 allows you to adjust the gas ow on the manometer without unwinding the supply wire. Once started,

the proceedure is illustrated with an animation on the screen. The gas ow setting should be checked periodically to ensure optimal welding.

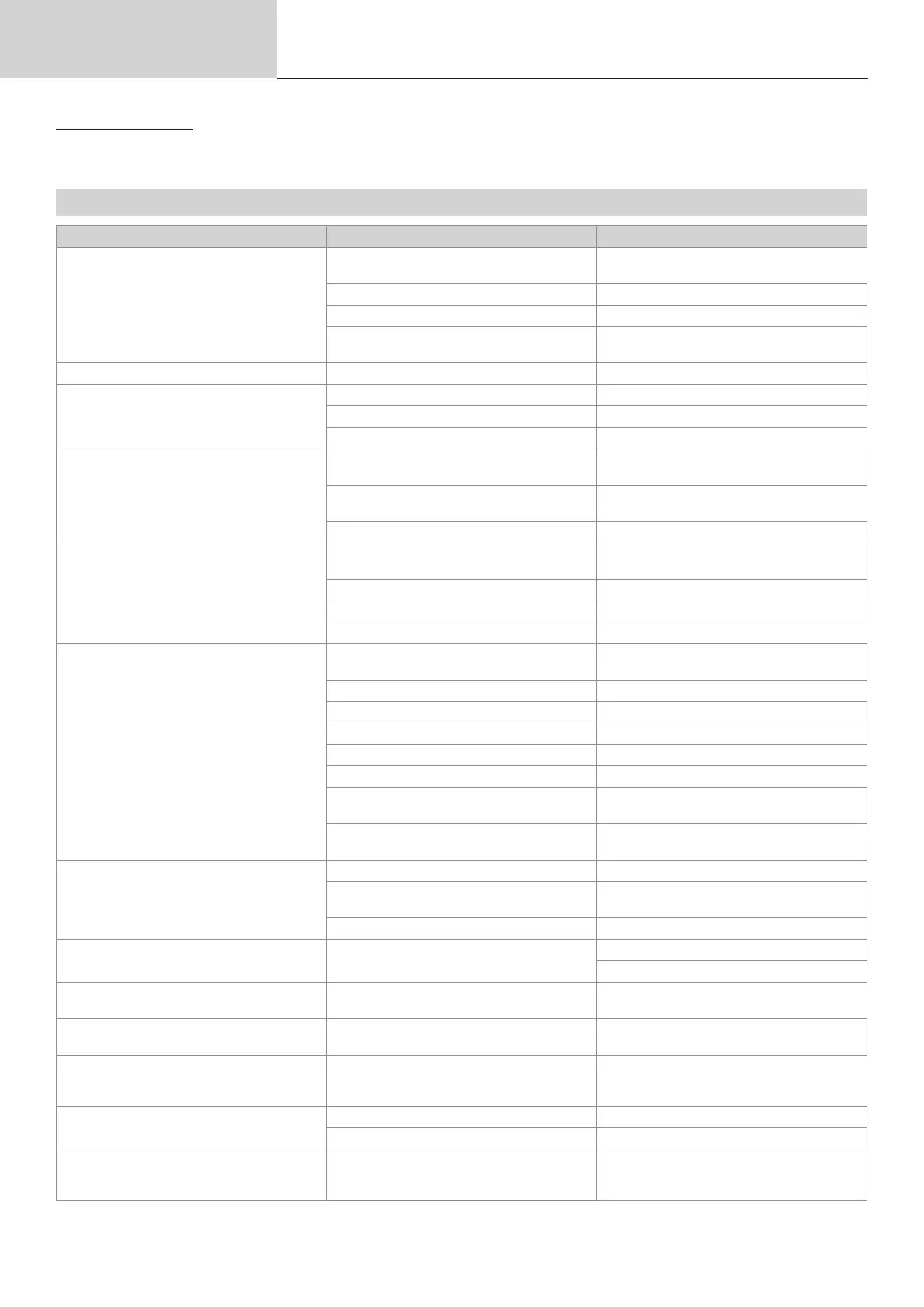

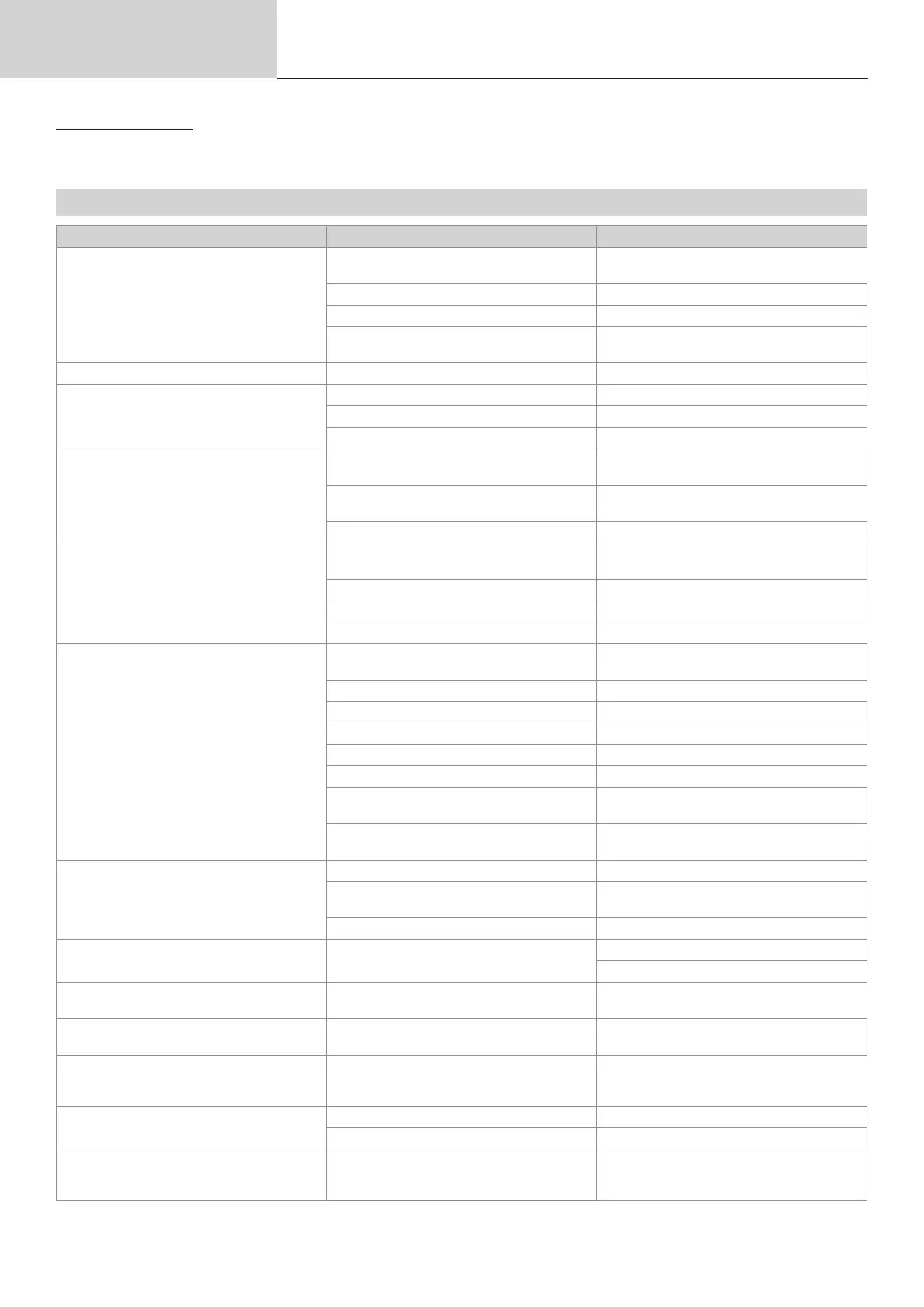

DEFECTS: CAUSES & SOLUTIONS

SYMPTOMS POSSIBLE CAUSES SOLUTIONS

The ow rate of the welding wire is not

constant.

Clogs blocking the opening.

Clean the contact tube or replace it with non-

stick material.

The wire is slipping on the rollers. Reapply the non-stick product.

One of the rollers is spinning. Check the tightness of the roller screw.

The torch cable is twisted.

The torch cable should be as straight as

possible.

The unwinding mechanism is not working. The spool’s brake or roller is too tight. Loosen the brake and rollers.

Incorrect unwinding of the wire.

Dirty or damaged wire guide. Clean or replace.

Roller pin key is missing. Reposition the pin in its slot.

Spool’s brake is too tight. Release the brake.

No current or wrong welding current.

Incorrect mains outlet connection.

Check the plug connection and verify that the

plug is connected to the power supply.

Poor earth connection.

Check the earthing cable (its connection and

the condition of the clamp).

No power. Check the torch trigger.

The wire jams after passing through the

rollers.

Crushed wire guide sheath.

Check the wire-guide sheath and body of the

torch..

Wire blockage in the torch. Replace or clean.

No capillary tube. Check that the capillary tube is present.

Wire speed too high. Reduce the wire speed.

The weld bead is porous.

The gas ow is insucient.

Adjustment range from 15 to 20 L / min.

Clean the base metal.

Gas cylinder empty. Replace it.

Unsatisfactory gas quality. Replace it.

Air circulation or wind inuence. Avoid draughts and protect the welding area.

Gas nozzle is too clogged. Clean or replace the gas nozzle.

Bad wire quality. Use a wire suitable for MIG/MAG welding.

Condition of the welding surface is too poor

(rusted, etc.).

Clean the workpiece before welding.

The gas is not connected.

Check that the gas is connected to the power

source’s inlet.

Excessive sparks.

Arc voltage is too low or too high. See welding settings.

Poor earth connection.

Check and position the earth clamp as close

as possible to the area to be welded.

Insucient gas protection. Adjust the gas ow.

No gas coming from the torch. Poor gas connection.

Check the connections of gas inlets.

Check that the solenoid valve is working.

Error while downloading.

The data on the USB stick is incorrect or

corrupted.

Check your data.

Backup error.

You have exceeded the maximum number of

backups.

You need to delete some programs.

The number of backups is limited to 200.

Automatic deletion of JOBS.

Some of your JOBs have been deleted

because they were incompatible with the new

pre-installed user settings (synergies).

-

USB key error.

There is no JOB detected on the USB stick. -

The product’s memory space is full. Free up some space on the USB key.

File error.

The le does not match the pre-installed

user settings (synergies) downloaded to the

product.

The le was created with pre-installed user

settings (synergies) that are not present on the

machine.

Loading...

Loading...