8

Using the machine interface

Control of the power source

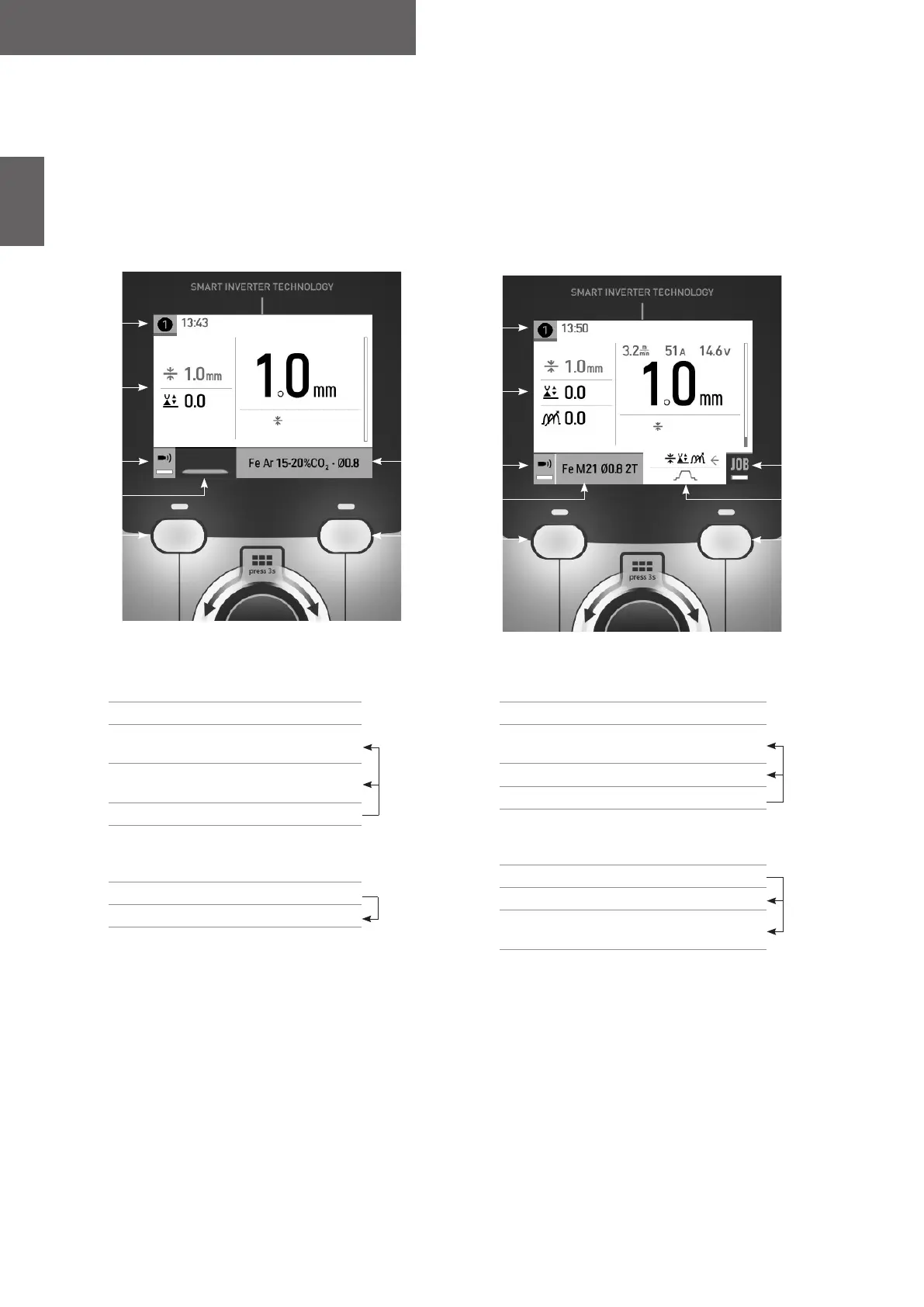

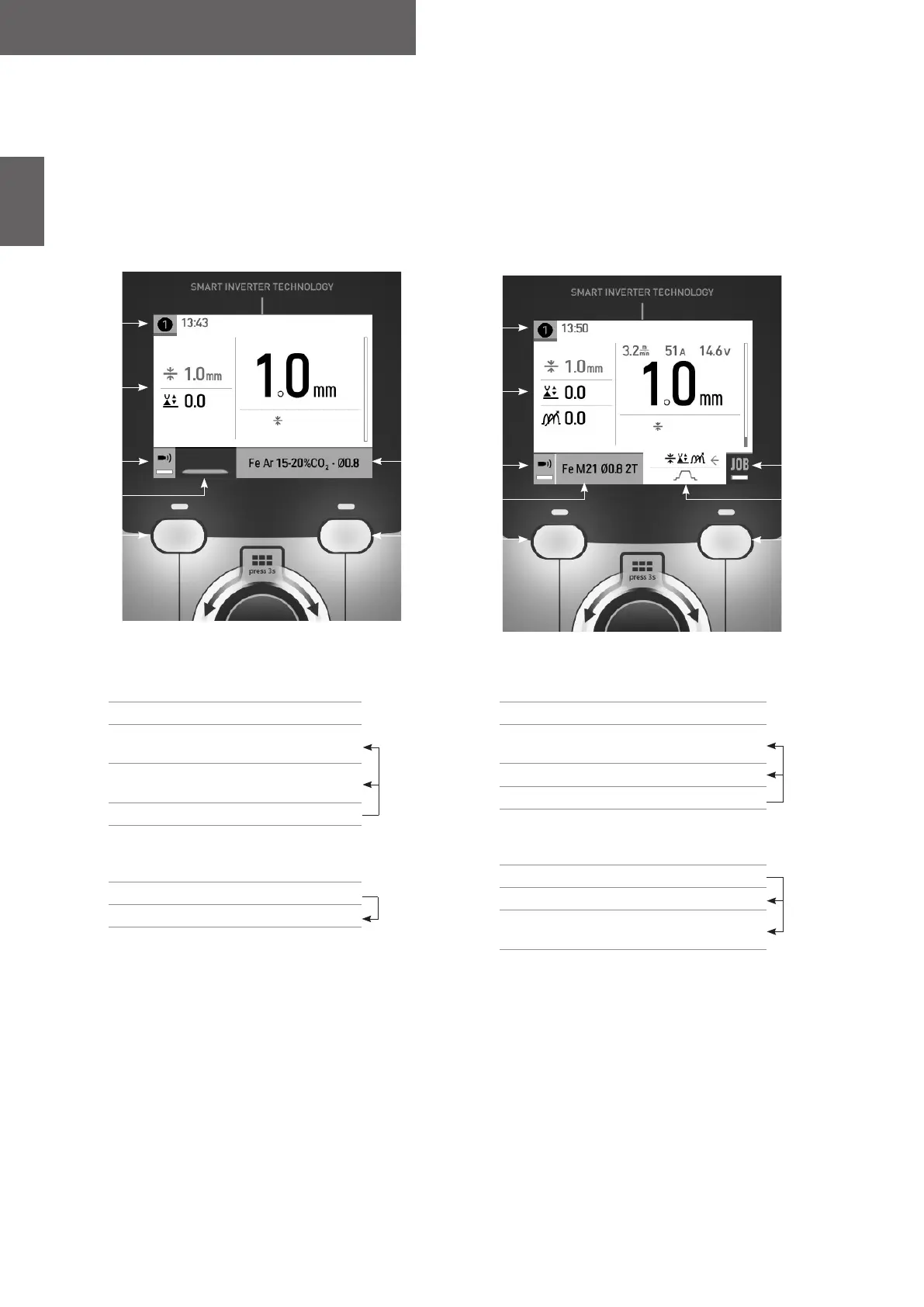

The main screen displays all the information needed before, during, and after welding.

The interface is adjustable with 2 dierent display modes: Easy or Expert.

Easy Expert

Thickness

Welding

1

2

3

4

8

5 7

6

1

2

3

4

9

5 7

6

Thickness

8

1

Torch used (E2 / E3)

Schedule

2 Current settings

3

Long press BP1

Gas ow control

4

Welding mode choice:

Welding/Spot-welding/Chain-stitch

5 Push-button no. 1 (BP1)

6

Navigation thumbwheel

Short press to conrm

Long press = General menu

7 Push-button no. 2 (BP2)

8 Current process settings

1

Torch used (E2 / E3)

Schedule

2 Current settings

3

Long press BP1

Gas ow control

4 Current process settings

5 Push-button no. 1 (BP1)

6

Navigation thumbwheel

Short press to conrm

Long press = General menu

7 Push-button no. 2 (BP2)

8 Advanced settings

9

Long press BP2

Access to JOB

Easy Mode:

This streamlined display mode is ideal for achieving optimum weld quality.

- 3 welding modes: Welding, Spot-welding and Chain-stitch

- 4 settings : Choice of welding material (synergies), ller wire diameter, thickness, and arc length.

Expert Mode :

This more extensive display mode is designed for more experienced welders.

- Welding modes: Synergic or Manual

- Trigger behaviour: 2T or 4T

- Spot modes: Spot and Spot-Delay

- Selection of the main setting to be presented on the display

- Full adjustment of the welding cycle: Longueur d’arc, inductance, Pré-gaz, Hot Start, Burn Back, Post gaz, etc

Loading...

Loading...