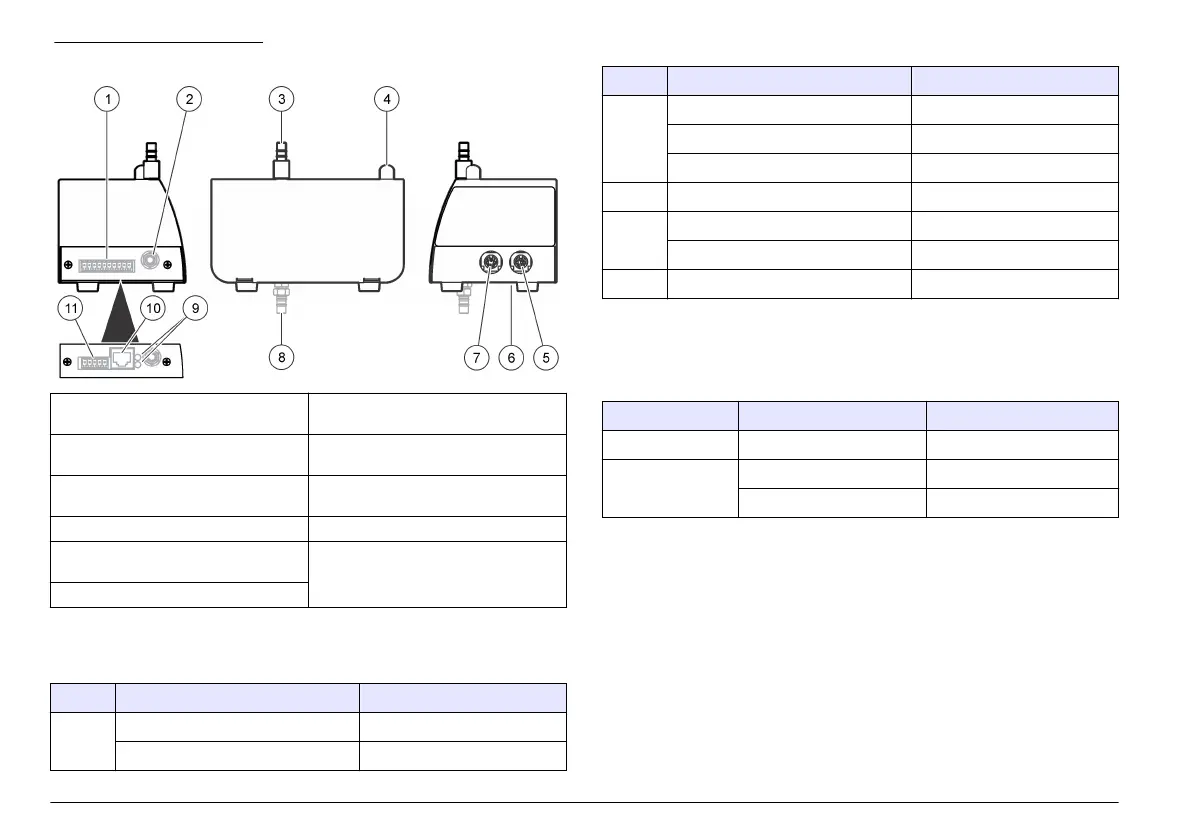

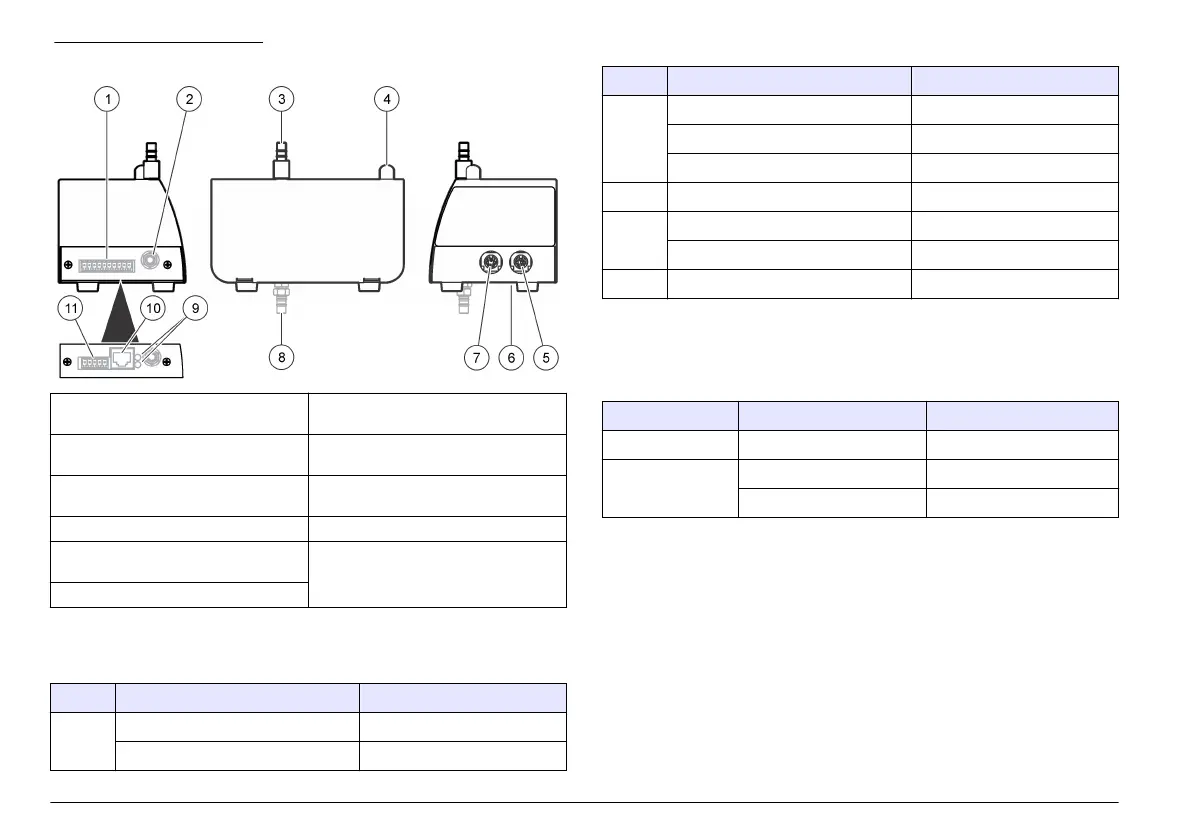

Figure 1 Product overview

1 Power input and communication

connector, 10-pin

1

7 Relative humidity (RH) and

temperature sensor port

2 Vacuum source fitting (or quick-

connect fitting)

8 Vacuum source fitting (alternate

location)

3 Sample air inlet fitting 9 Connection indicator lights

2

(Table 2)

4 Status indicator light (Table 1) 10 Ethernet RJ45 connector

2

5 Service port and optional light stack

port

11 Power input connector, 5-pin

2

6 DIP switch, network address

1

1

All units except Ethernet

2

Ethernet units only

Table 1 Status indicator light

Color Indication System status

Green Flashing (3 seconds) Normal, sampling

On Normal, not sampling

Table 1 Status indicator light (continued)

Color Indication System status

Blue On Sensor failure

One short flash, one long flash Air flow failure

Flashing Communication failure

Red On or flashing Count alarm

Yellow On Initialization

Flashing Count alert

1

Purple Flashing Setup utility is being used

1

The user-supplied central monitoring software can be used to make the yellow

light flash when a count alert occurs with ModBus protocol, not FX protocol.

The count alert settings are selected with the central monitoring software.

Table 2 Ethernet indicator lights

Color Indication Status

Yellow On Connected

Green Off 10Base-T

On 100Base-T

Isokinetic probe

For the best accuracy in laminar flow environments, always use the

supplied isokinetic probe with this

instrument. The velocity of air in the

probe is similar to that of a typical vertical or horizontal laminar flow

environment such as a clean room or clean hood. The supplied

isokinetic probe supplies the same vertical (or horizontal) flow speed of

the air in order to collect representative samples of the clean room

laminar flow for the instrument. Refer to Figure 2 for a comparison of

sampling with and without the isokinetic probe.

6 English

Loading...

Loading...