11

6. OPERATION

D-1 Setting method in AUTO/INSTALL

mode

●

Operations in INSTALL mode

This mode has the following sequence:

①

Vacuum ON (Manual)

②

Start/hot air blow (Manual)(Step/start)

③

Vacuum OFF after 5 seconds

④

Step 1 operation

⑤

Step 2 operation

⑥

Step 3 operation

⑦

Cool down operation

NOTE:

The operation can be set from 1 to 3.

●

Installation

•

Advance preparation of P.W.B.

Apply an appropriate amount of solder paste

to the P.W.B.)

①

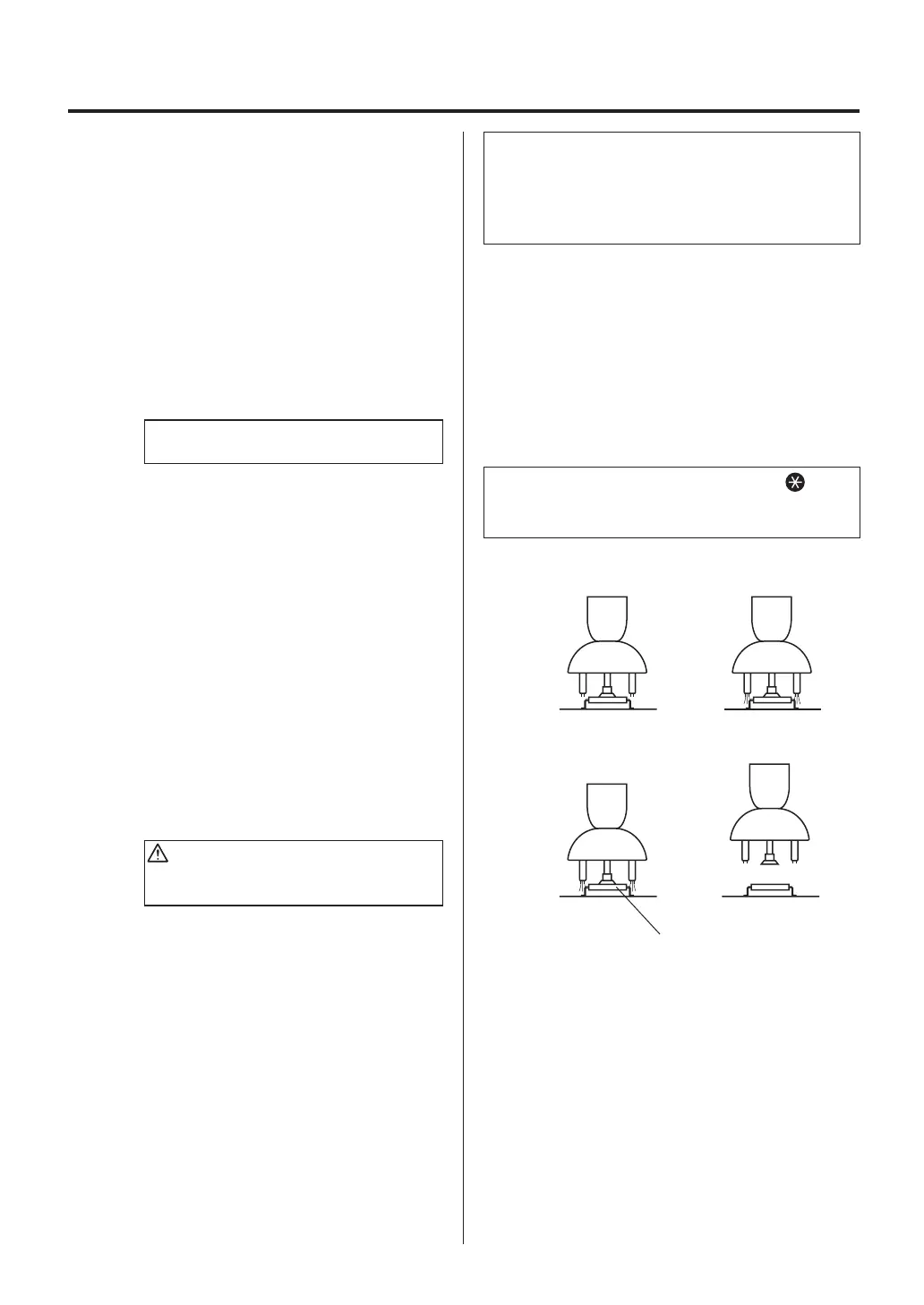

Part suction and positioning

Press the VACUUM button on the

handpiece. Have the part sucked by the

pads and position the part on the P.W.B.

(Figure 1)

②

Start (heating)

Press the HOT button on the handpiece.

Hot air blows from the nozzle to melt the

solder. The station operates based on

the preprogrammed temperature profile.

(Figure 2)

CAUTION

To stop the program, press the HOT AIR

button. Cooling begins.

③

Vacuum stop

After 5 seconds, the vacuum turns OFF

and the part is released from suction.

(Figure 3)

④

Stop

When the step operation is completed,

cooling begins. Make sure the solder has

hardened before lifting the handpiece.

(Figure 4)

To check the temperature setting, press the

button. To change the temperature setting, see “Setting

method in AUTO mode” on page 13.

In INSTALL mode, press the HOT AIR button after

turning the vacuum function ON manually and

aligning the component on the PWB. Vacuum function

automatically will turn OFF 5 seconds after starting

selected the profile.

②①

④③

Figure 1 Figure 2

Figure 3 Figure 4

Vacuum OFF

Loading...

Loading...