31

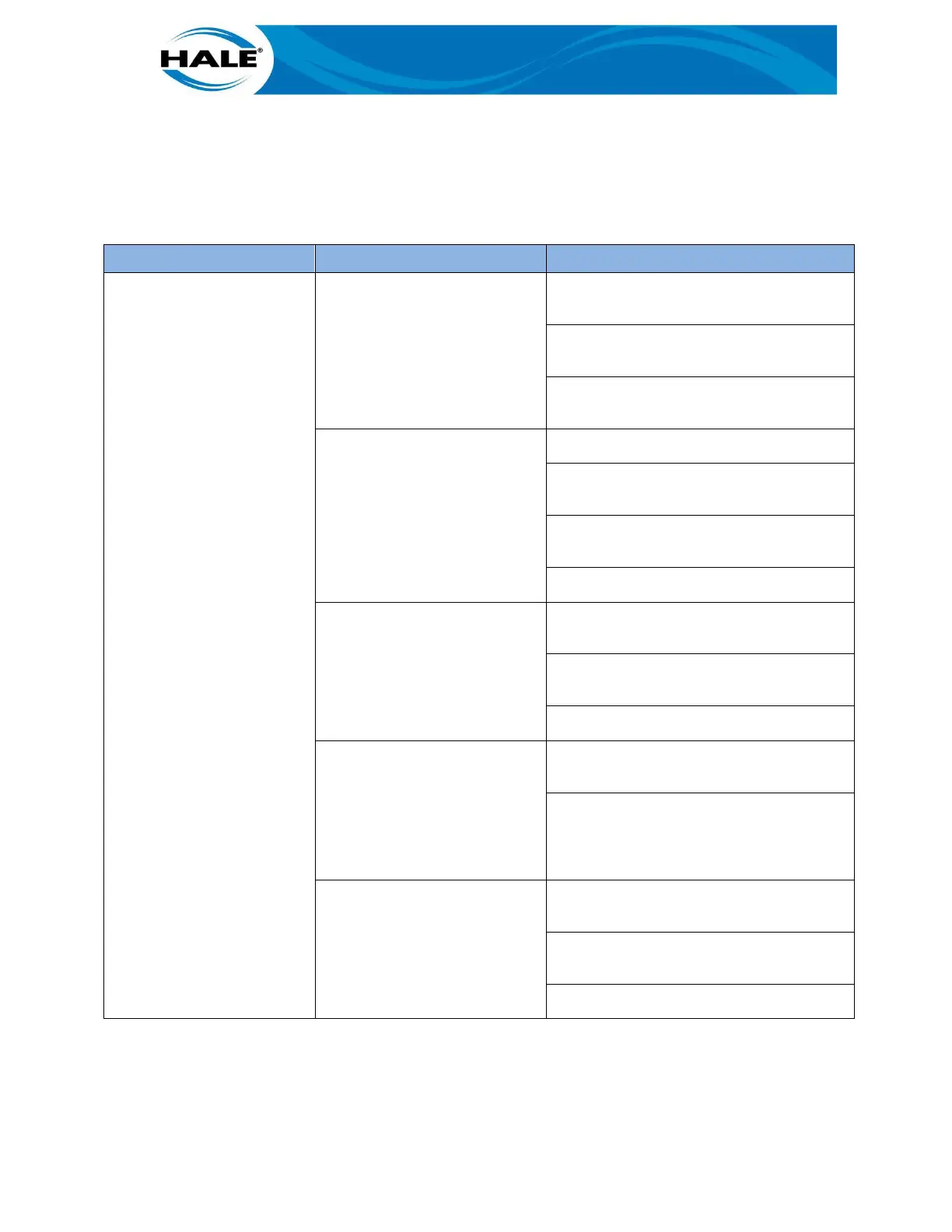

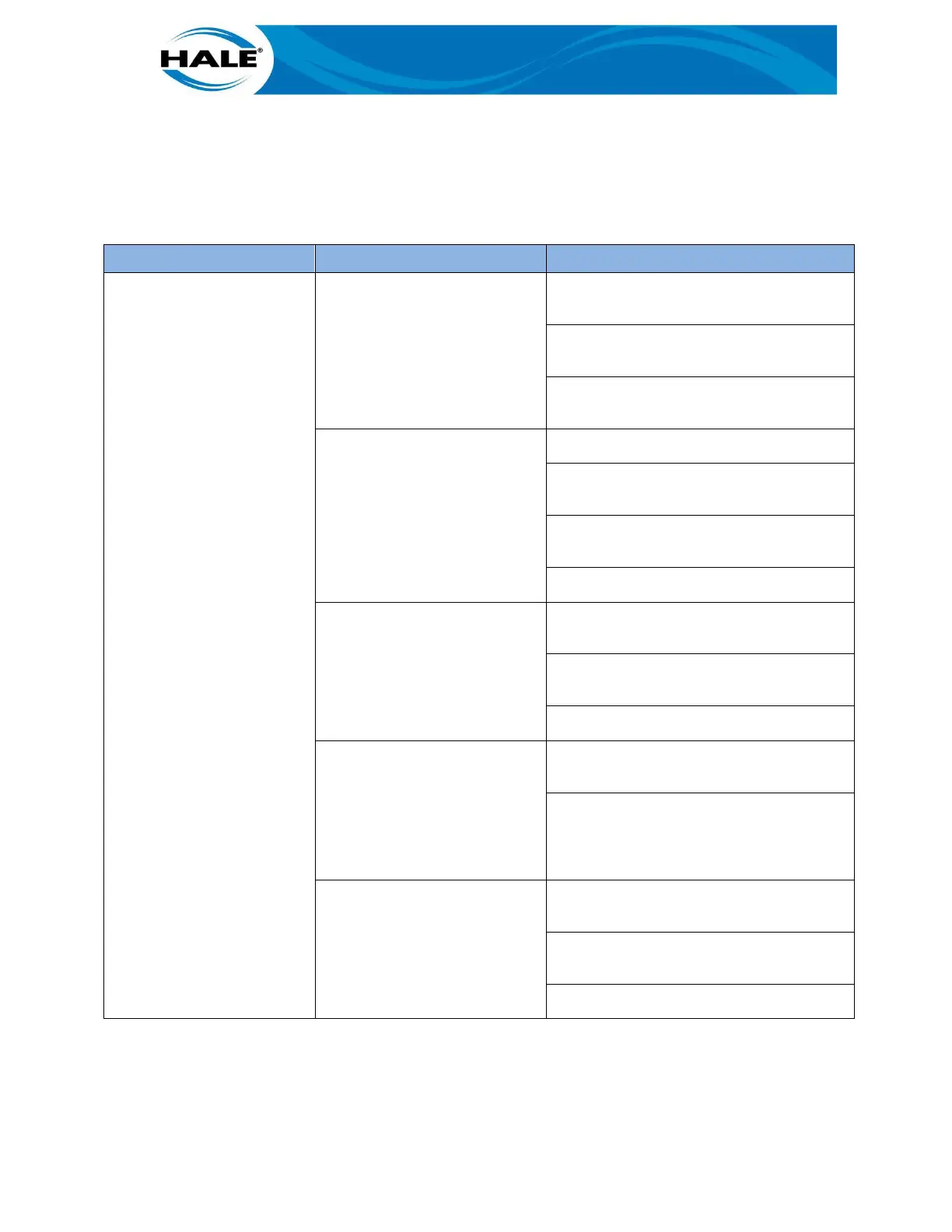

8.2.1 Cavitation Symptoms, Causes, And Remedies

Table 7 provides the primary symptoms, causes, and remedies for troubleshooting cavitation issues.

Cavitation limits pump performance and can damage the pump. Refer to Technical Manual for more

information.

Table 7. Cavitation SCR Table

Pump Is Cavitating

• Pump makes excessive

rattling noise while

pumping and/or un-

steady discharge pres-

sure gauge.

• Note as the throttle is

increased there should

be a corresponding in-

crease in pump dis-

charge pressure. If the

throttle is increased and

the discharge pressure

does not increase or de-

creases, the pump is op-

erating in cavitation.

Operating Beyond Pump Capa-

bility

Reduce pump’s RPM to either reduce flow

rate and/or reduce discharge pressure.

Gate the discharge valve(s) to reduce flow

and maintain pressure.

Add more and/or larger intake lines to in-

crease flow rate to pump.

Intake Restriction

• Collapsed Suction Hose

• If Equipped, Partially Closed

Intake Valve(s)

• Suction Hose Strainer

Clogged

Replace with different hose(s).

If equipped, make sure all intake valves are

fully opened.

Clean strainer and remove debris from wa-

ter around strainer.

Keep strainer off bottom of water source.

Pump Too Far From Water

Source

• Suction Hose Too Long

• Suction Lift Too High

Move pump closer to water source and re-

move a section length of suction hose or.

Use a larger diameter size of suction hose

or.

Operate pump at a reduced flow rate.

Exceeding Capacity Of Supply

Source

• Hydrant Operation

• Relay Operation

Do not reduce the pressure on the intake

gauge below department limits.

If department does not have an intake

gauge pressure limit, do not allow intake

gauge pressure to fall below 15 psig

(105 kPa).

Water Temperature Too High Reduce pump’s RPM to either reduce flow

rate and/or reduce discharge pressure.

Gate the discharge valve(s) to reduce flow

and maintain pressure.

Locate a source of cooler water.

Loading...

Loading...