46 USE ONLY GENUINE REPLACEMENT PARTS

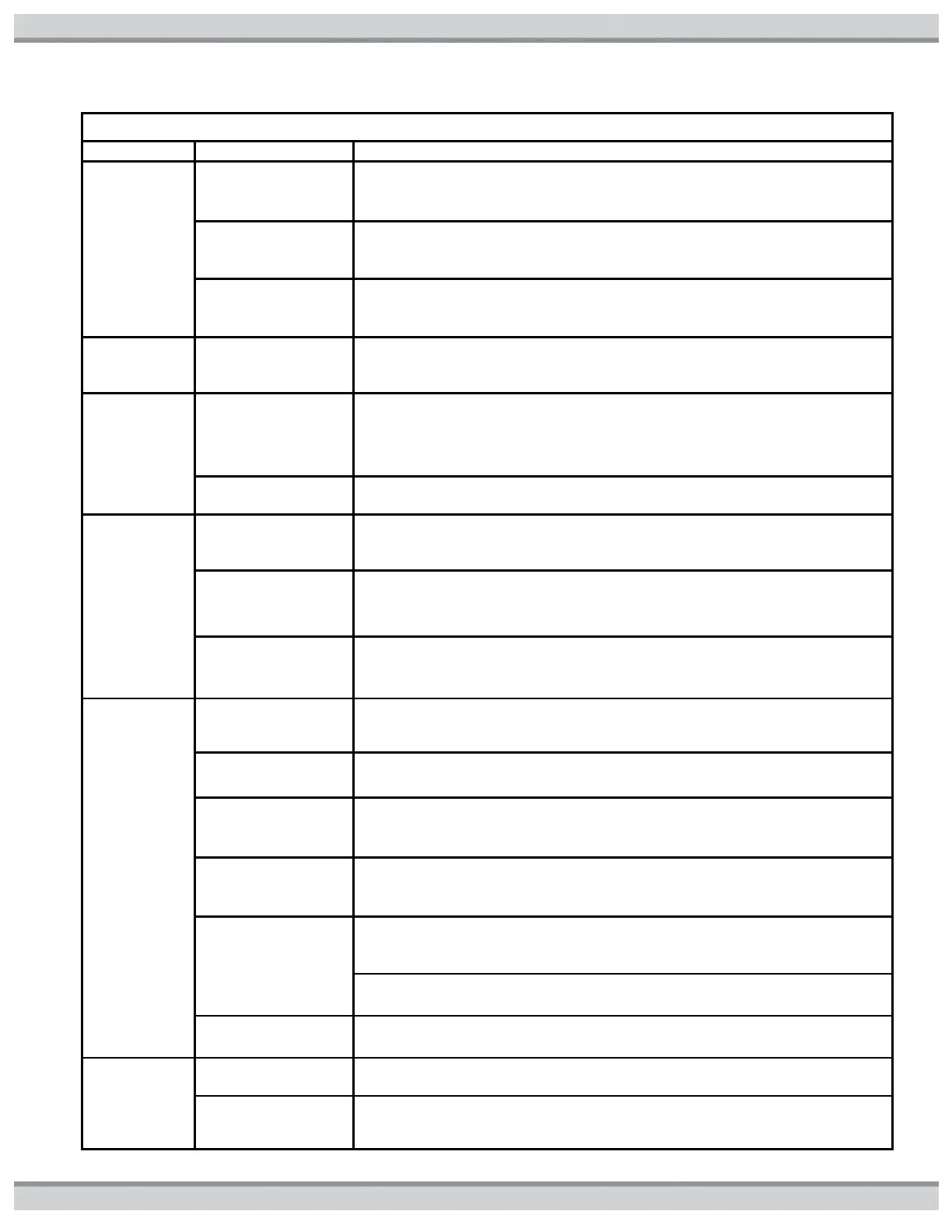

Table17: Troubleshooting Lookup Chart

Suggested Troubleshooting Action

CE

displayed

Control to

display

communica-

tion error

1. Disconnect and

then re- connect

power to heater.

Reset communication between Display Interface and Ignition control board

2. Check for faulty

wiring or

connection.

Inspect Display Interface Wiring. Ensure Display Interface Plug is securely

attached to ignition control board. If OK, proceed to step 3.

3. Display Interface

and/or Ignition control

board are defective.

Replace Display Interface and/or ignition control board

1. EEPROM error

Defective ignition

control board

Replace ignition control board.

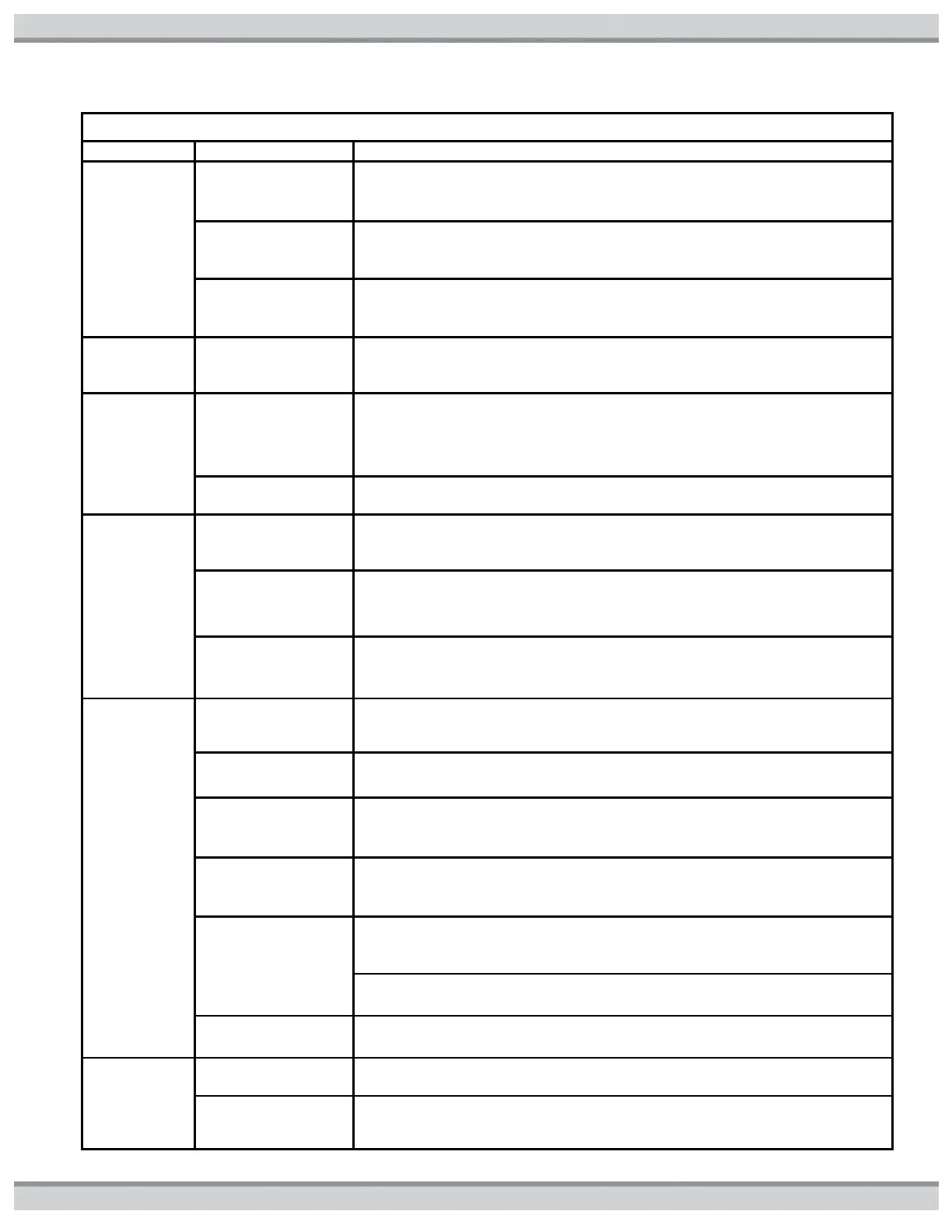

HF

displayed

High flame

sensor signal

error

1. ignition control

board is defective

Using the sight glass, check to see if the flame is present in the unit. If not,

replace ignition control board. If flame is present, use a voltmeter to

determine if 24 VAC is present at the gas valve connections. If so, replace

ignition control board. If not, move to step2.

2. Gas Valve is

defective

HS

displayed

High temp.

sensing Error

1. Check remote

thermostat setting

Verify set point setting of remote thermostat is at or below 104°F. If set

point of remote thermostat is OK, or if heater is not configured for remote

thermostat, proceed to step 2.

2. Verify that the

water flow is

adequate

Verify that water flow to heater is above minimum required (see

SPECIFICATION in Getting Started Section). Note that intermittent periods

of low water flow will cause this error. If OK, proceed to step 3.

3. Check inlet water

temperature sensor

Compare the heater's temperature reading to the pool water temperature

with an accurate thermometer. If significantly different, replace inlet water

temperature sensor.

IF

displayed

Ignition

failure error

1. Ensure gas

supply shut off

valves are open.

Ensure that main gas shutoff installed adjacent to heater is open. Ensure

that knob on gas valve inside unit is in ‘‘on’’ position. If OK, proceed to step

2.

2. Check for low

gas supply press.

Ensure inlet gas supply pressure is between the minimum and maximum

values indicated on rating plate. If OK, proceed to step 3.

3. Check for faulty

flame sense

connection.

Inspect flame sense wiring. Ensure wire harness terminals are securely

fastened to flame sense and to ignition control board. If OK, proceed to

step 4.

4. Check for faulty

gas valve

connection

Inspect gas valve wiring. Ensure wire harness terminals are securely

fastened to spade terminals on gas valve. If OK, proceed to step 5.

5. Check for gas

valve failure or gas

valve relay failure.

1. Measure voltage across gas valve during trial for ignition. If 24VAC is

present and gas valve does not open, gas valve is defective. Replace gas

valve.

2. If 24VAC is not present, gas valve relay on ignition control board is

defective. Replace ignition control board.

Inspect gas orifices for blockages which could prevent gas flow. Remove

and inspect burners for blockages.

IO

displayed

Igniter open

error

1. Check for faulty

connection.

Inspect Igniter wiring. Ensure Igniter Plug is securely attached to ignition

control board. If OK, proceed to step 2.

Loading...

Loading...