13

T210

ELECTRICAL CONNECTION

Measuring cables should not be laid parallel to power cables and control circuits (that is,

not in shared cable ducts). If this is not possible, protect the measurement cable with a

rigid steel conduit, for example, and keep it as far away from other cables as possible.

Avoid stray fields from transformers, motors and contact switches.

Notice

At the maximum rotational speed of 30,000 rpm the cable length is limited to maximum

10 m.

5.4 Shielding design

The cable shield is connected in accordance with the Greenline concept. This encloses

the measurement system in a Faraday cage. It is important that the shield is laid flat on

the housing ground at both ends of the cable. Any electromagnetic interference active

here does not affect the measurement signal.

In the event of interference due to potential differences (compensating currents), discon

nect supply voltage zero from the housing ground at the measuring amplifier and lay a

potential equalization line between the transducer housing and the measuring amplifier

housing (copper cable, 10 mm

2

cable cross-section).

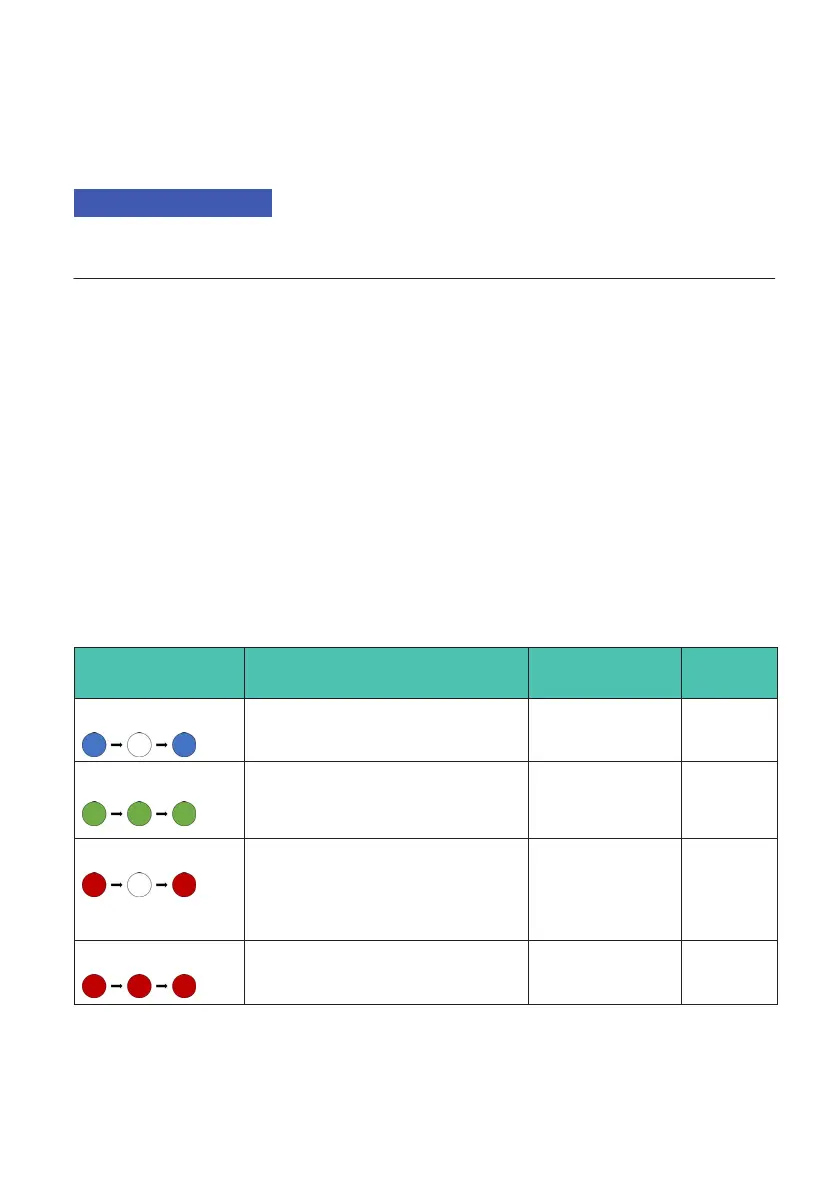

5.5 Status LED

The transducer has a status LED. The various states are shown in table Tab. 5.1.

LED Description Analog output

signals

Output

status

Flashing blue Boot-up

Measurement shaft is started.

-14 V and 0 Hz LOW

Lit green Ready for operation

Measurement shaft ready for

measurement.

Measurement

signal

HIGH

Flashing red Warning

Non-critical state. Technical spec

ifications are no longer guaran

teed.

Measurement

signal

LOW

Lit red Error

Critical state. Stop operation.

Error signal LOW

Tab. 5.1 Various LED states

Loading...

Loading...