20

rod pushes the piston forward. The brake fluid in the cylinder flows back to the reserve

tank through the return port until the primary cup blocks up the return port. After the

primary cup passes through the return port, the brake fluid in the cylinder is pressurized

and opens the check valve, flowing through the brake pipeline to the sub cylinder. Thus,

each sub cylinder piston is forced outwards. This brings the friction pieces on the brake

shoes into contact with the brake drum and slows or stops the truck. Meanwhile, the

cavity caused behind the piston is filled with brake fluid led through the return port and

inlet port. When the brake pedal is released, the piston is forced back by the return spring.

At the same time, the brake fluid in each sub cylinder is pressured by the return spring,

returning into the mast cylinder through the check valve. With the piston in its original

position, the fluid in the master cylinder flows into the reserve tank through the return

port. The brake fluid in the brake pipelines and sub cylinders has a residual pressure

proportioned to the set pressure of the check valve, which makes each sub cylinder piston

cup securely seated to prevent oil leakage and eliminates a possibility of air locking when

the truck is sharply braked.

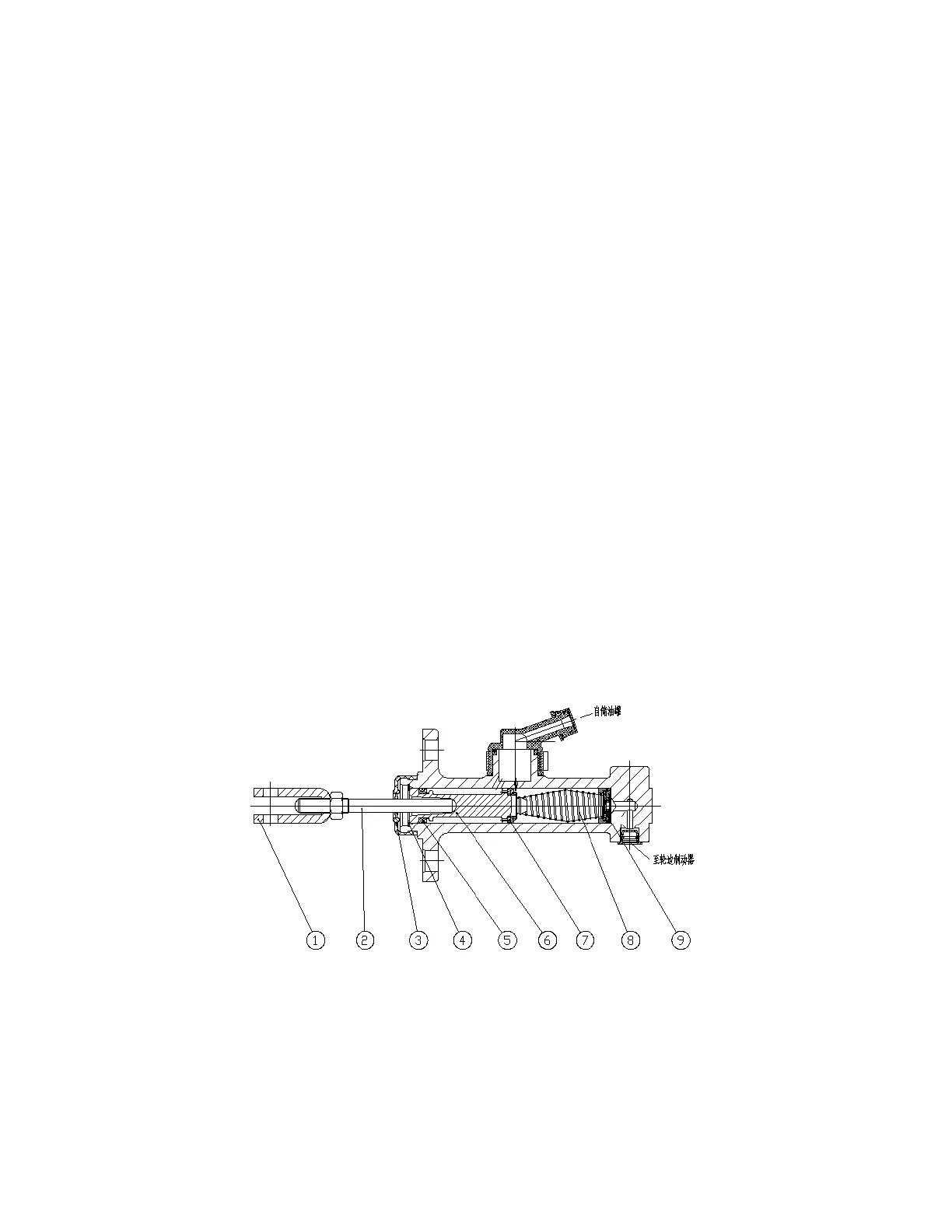

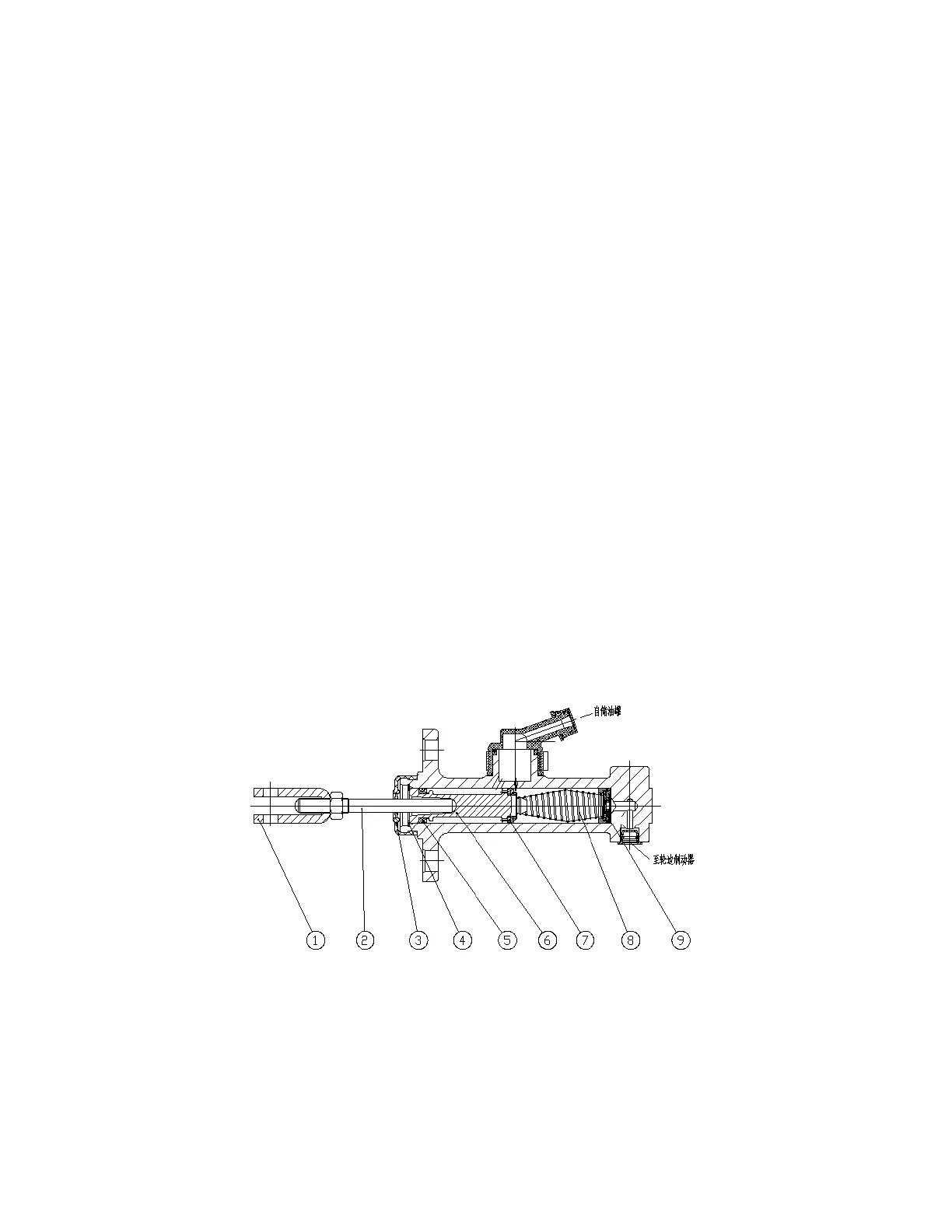

Fig. 2-2 Master cylinder

(1) Connecting rod (2) Push rod (3) Dust cover (4) Snap ring (5) Secondary cup

(6) Piston (7) Primary cup (8) Spring (9) Check valve

2.1.3 Service brake

The service brake is of double brake shoe type which is fitted to the each end of the

Loading...

Loading...