ENDE

Operating Instructions • Overhead Suspension AT2000 CPK • 03/2020 • 106-29021

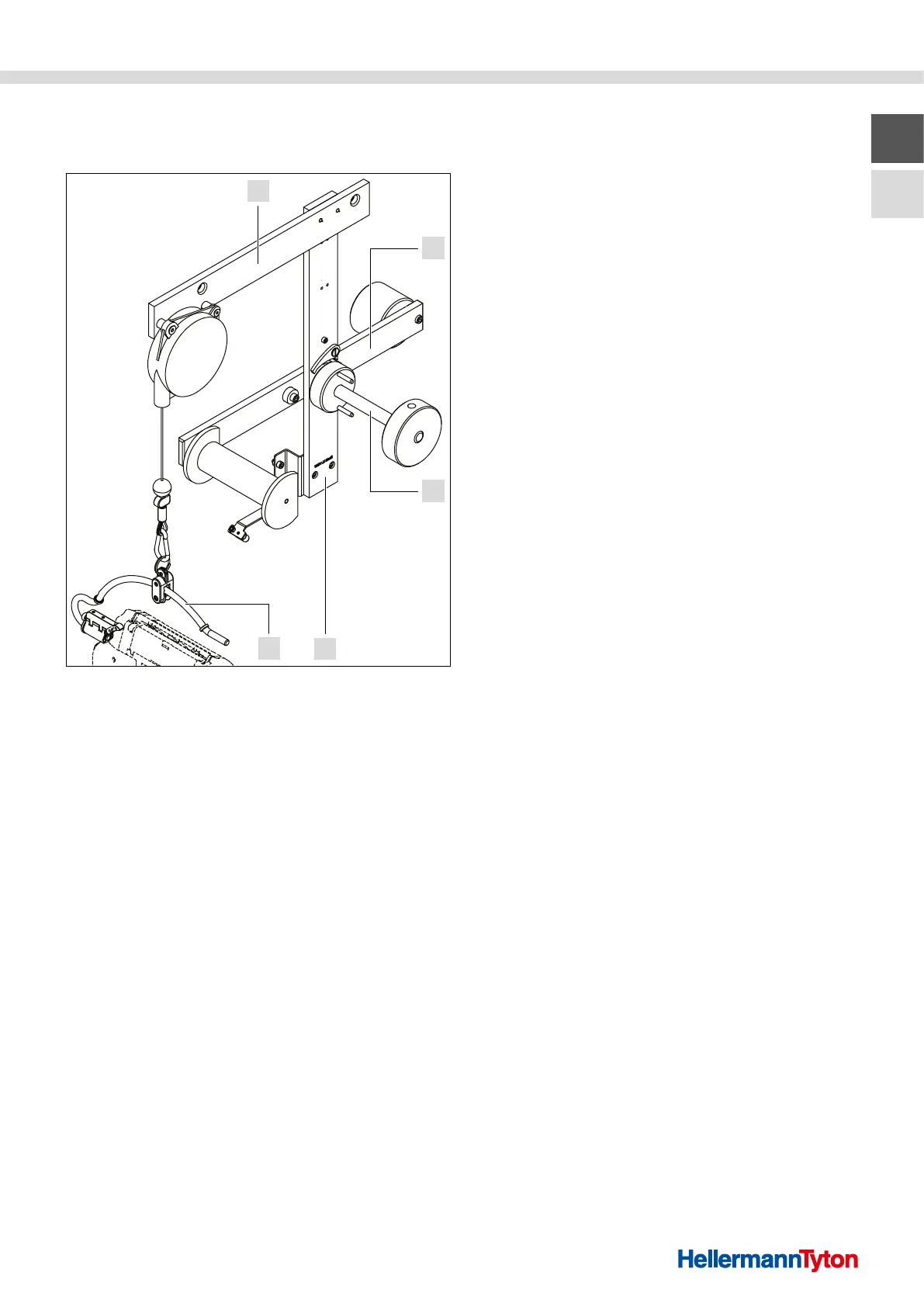

Layout and function

7

3 Layout and function

3.1 Layout

4

1

3

2

5

Overview of the AT2000CPKoverheadsuspension

1 Rail runner with balancer (cable pull)

2 Band chain tensioner with guide roller and counterweight

3 Reel retainer with clamp ring

4 Column with power supply unit bracket

5 Hanger with adapter

3.2 Scope of delivery

The overhead suspension is delivered with the

following components and fixing elements:

• 1× rail runner with balancer (cable pull)

• 1× column with power supply unit bracket

• 1× reel retainer with clamp ring

• 1× band chain tensioner with guide roller and

counterweight

• 1× hanger with adapter

• 1× locking pin (adapter)

• 2× fixing screws (adapter)

• 2× fixing screws (rail runner)

• 4× fixing screws (power supply unit bracket)

• 1× cap nut with washer

• 1× operating instructions

f Check the scope of delivery for completeness before

starting installation.

3.3 Function

The AT2000CPKoverheadsuspension is used to

install the Autotool2000CPK tool in a hanging

position at the workplace. This hanging position

enables flexible and trouble-free work with the

Autotool2000CPK tool at the workplace.

The Autotool2000CPK tool is hooked on a balancer

(cable pull) using a hanger supplied. The balancer

ensures weight compensation making it easier for the

operator during use.

4 Transport and storage

Only proper transport and proper storage help to

minimise possible material damage to the overhead

suspension.

Observe the following basic principles regarding

transport and storage:

f Secure all moving components.

f Only use the original packaging supplied for transport

and storage.

f Store the overhead suspension in dry places that are

not exposed to spray water.

f Protect the overhead suspension from direct sunlight

and extreme heat.

f The electronic components (e.g. Autotool2000CPK,

CPKpowersupplyunit, and their cables) must be

packaged protected against impact and stored

separately from the overhead suspension.

Loading...

Loading...