52

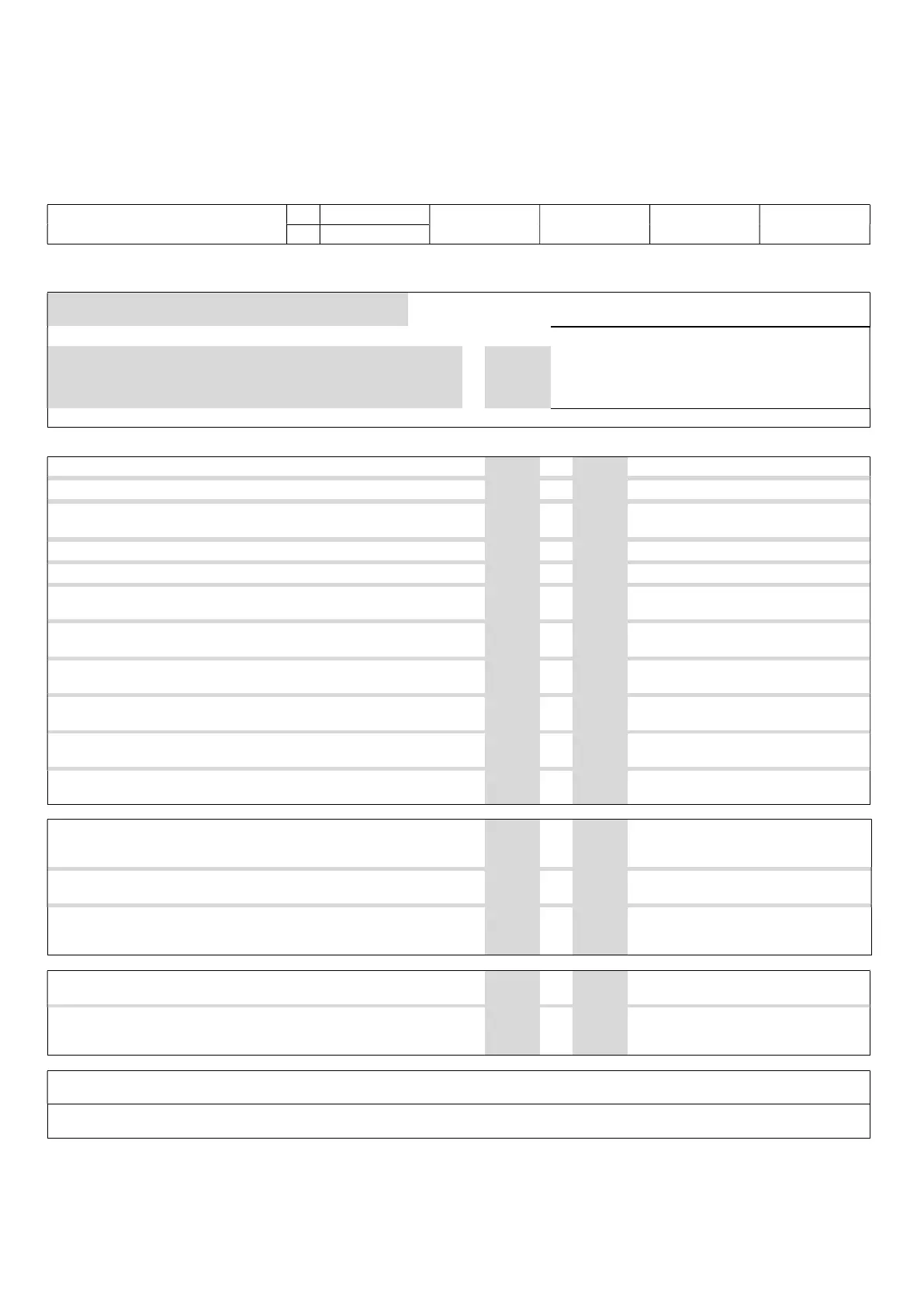

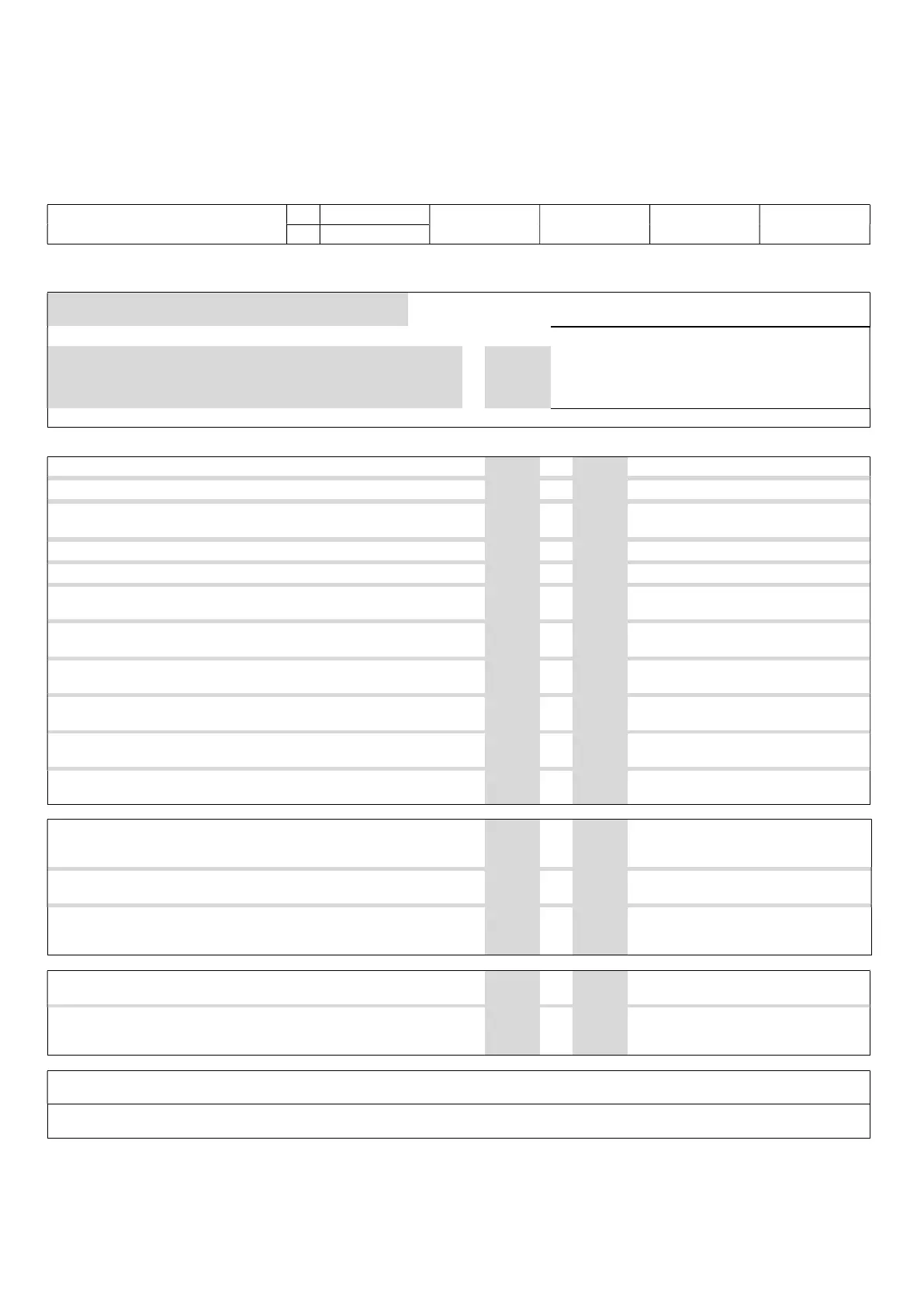

Check List Testomat 2000

®

Dear customers and service technicians,

This check list cannot replace your expertise or extensive experience in fault resolution. It is intended to support fast and systematic error diagnosis

and error documentation. This list does not claim to be complete. We are therefore always grateful for any advice and information you may be able

to provide. General user instructions can be found on the rear of this check list.

The Instrument Manufacturer

Block 1 / Plant and instrument data

®

®

Block 2 / Error message and error history Please mark appropriately (X)

What does your instrument’s error history display?

nd “Enter” key => operating instructions)

Does an error message appear on the display?

For example, “Mf. analysis”, “Low water level”, etc.

(See operating instructions: “Error messages /

Yes No

Block 3 / Visual inspection and functional test Please mark appropriately (X) If applicable, values / comments

Is the instrument connected to

the mains voltage specified on the rating plate?

Does the instrument display a plausible measured value?

(possible manual measurement ___________ value)

Yes No Measured value:

Are the measuring chamber and sight

easuring chamber and the water

carrying hoses free of leaks?

Is the indicator’s expiry date still valid?

(See expiry date printed on the indicator bott

Yes No Expiry date:

Is the water pressure within the specified range (400 ml/min)?

(See the type plate on the instrument)

Yes No Plant pressure:

Does the drain hose prevent the risk of backwater?

(No “syphoning effect”!!)

Yes No

Is the drain hose free of blockages?

Yes No

Does the set flushing time/quantity of flush water ensure that only freshwater

Yes No Flushing time:

Are the hoses at the dosing pump free from air bubbles?

(Operate the pump manuall

Yes No

CARRYING OUT A (MANUAL) ANALYSIS

Does the water column rise evenly up to the overflow borehole when filling the

measuring chamber (5 mm below the upper edge of the measuring chamber)?

(If not: check the water pre

Yes No

Does the indicator pump dose correctly when starting an analysis?

(LED at the pump illuminates!)

Yes No No. of dosing strokes:

Have the indicator and water been mixed properly in the measuring

chamber after the dosing process?

Check the magnetic stirring bar! =>see maintenance manual “Adjust mode”

Yes No

PROGRAMMING DATA / OPERATING CONDITIONS

Have the limit values been set correctly? (Within the measuring

range/according to the perf

Yes No Limit values:

Is the Testomat instrument always supplied with mains voltage – except

during maintenance work/emergency situations?

down only via the “Standby” key or the “Stop” input!)

Yes No See the “General instructions for

operating Testomat 2000

®

and

®

Please refer to “Error messages / Troubleshooting” in the operating instructions for further information on error messages and possible causes

Further functional tests (e.g. overflow detection and amplification setting => “Special function Adjust mode”) and service instructions can be found

After completing these checks, experience shows that it can be assumed that the checked functions (Block 3) are in effective working order if you

have answered all the questions with “Yes”. We recommend you to carry out these checks during each inspection or if faults occur.

Loading...

Loading...