Chapter 8. Troubleshooting

8-1

8. Troubleshooting

In case an error occurs during operation, take the following steps. If taking such steps does not

correct errors, contact our service center.

8.1 Servo Motor

Actions to be taken in case of errors

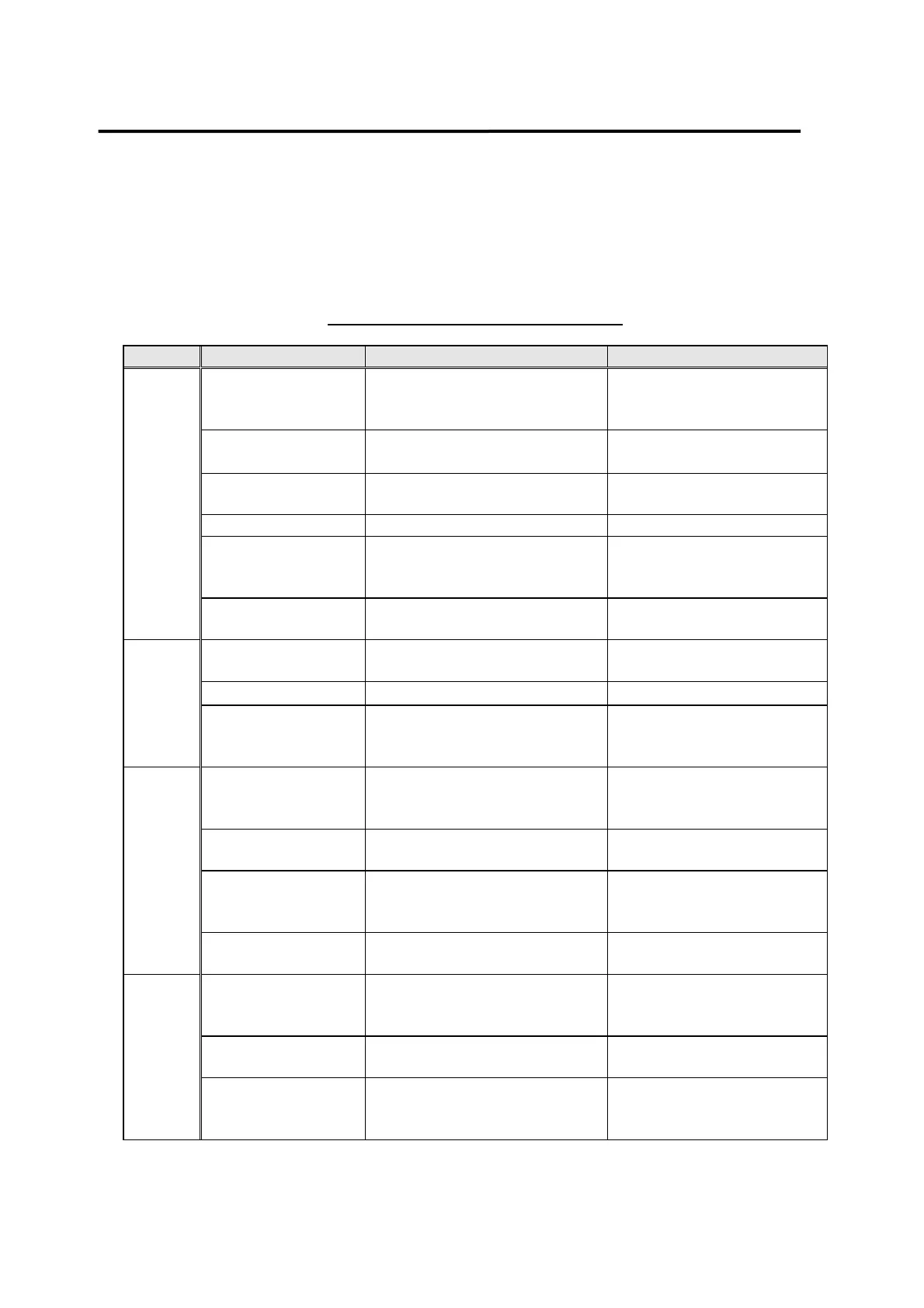

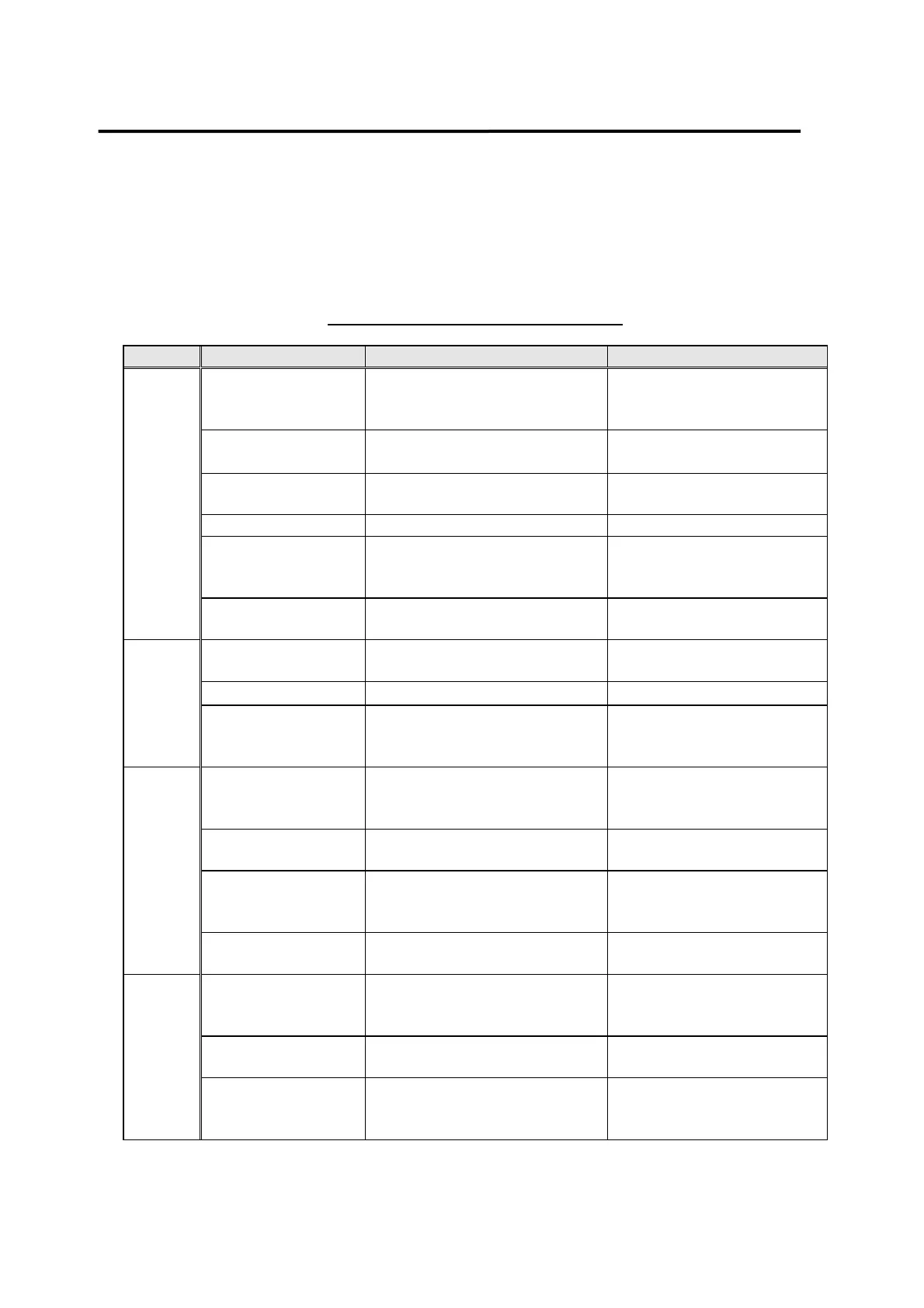

Symptom Cause Inspection Corrective action

Parameter setting is

incorrect

Check parameters related to

motor, encoder, encoder type

and control mode.

Reset parameters.

(See sections 5 and 6)

Overloaded

Check machine running

condition.

Readjust mechanical

systems.

Motor defective

Check motor lead terminal with a

tester.

If voltage is correct, replace

motor.

Screws loosened Check the screws. Retighten loose screws.

Incorrect external

wiring, or cable

disconnected

Check the motor and encoder

wiring.

Rewire.

Replace cable.

Motor

does

not start

Encoder defective Check the output wave form.

Replace encoder.

(Use A/S service)

Defective connection

Check connection of the motor

lead terminal.

Repair defective part.

Input voltage low Check drive input voltage. Change power supply.

Motor

running

unstable

Overloaded Check machine condition.

Remove foreign material from

the rotator and lubricate (or

grease) it.

Ambient temperature

high

Check the motor ambient

temperature. (Should be lower

than 40℃)

Change heat-shield structure.

Motor surface stained

Check motor surface for attached

foreign materials.

Clean the surface of the

motor.

Overloaded

Check the load rate of the drive.

Check acceleration/deceleration

cycle.

Reduce load.

Increase

acceleration/deceleration time

Motor

over-

heated

Magnetic power

deteriorated

Check counter electromotive

voltage and wave form.

Replace motor.

Defective coupling

Check the tightness of the

coupling screws and the

concentricity of joints.

Readjust coupling.

Defective bearing

Check the bearing for vibration or

abnormal noise.

Contact LG service center.

bnormal

noise

Parameter misset

(inertia ratio, gain,

time constant)

Check control parameters.

See Chapter 6. Parameter

Setting.

Loading...

Loading...