2. Wiring and connection

2-12

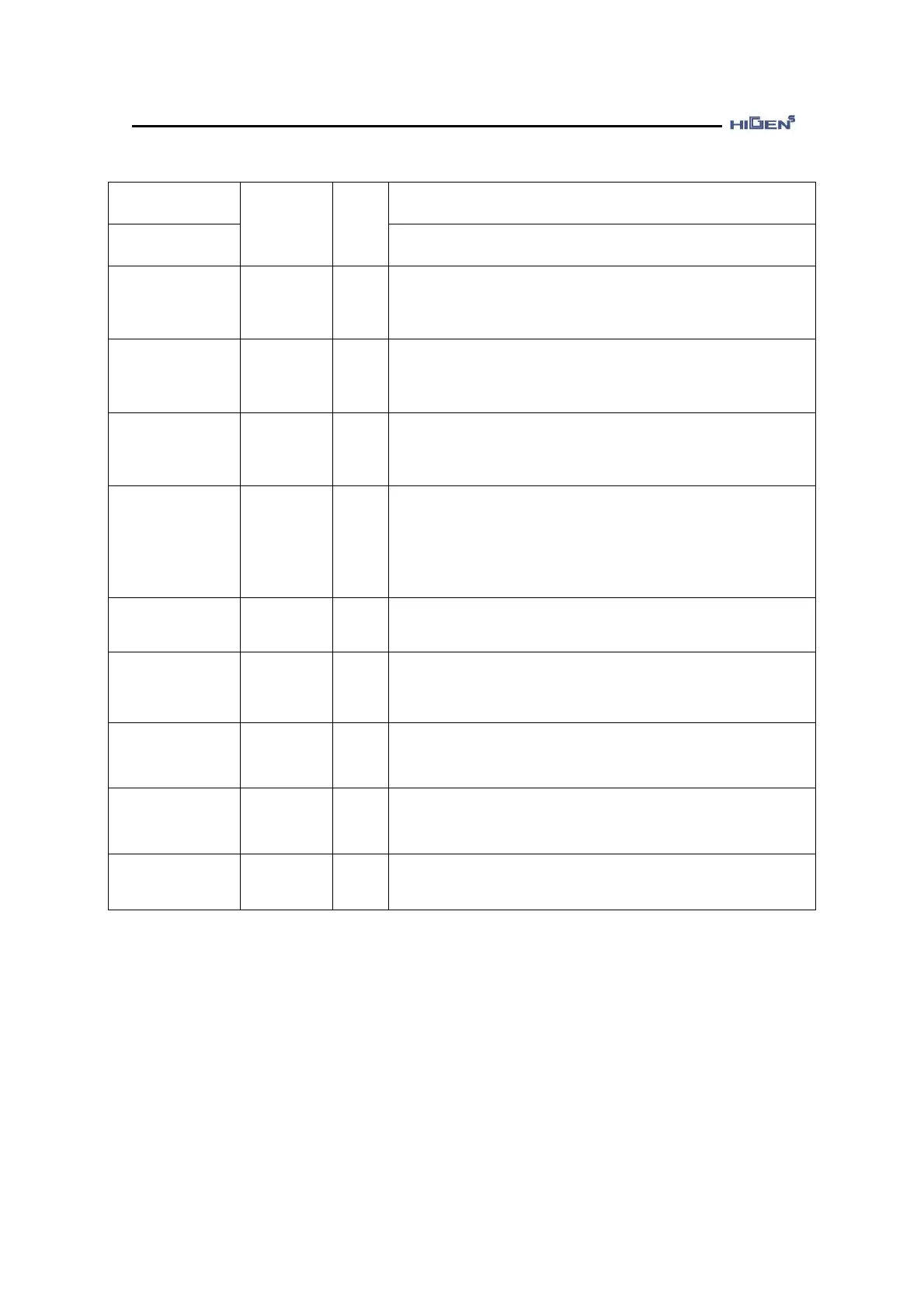

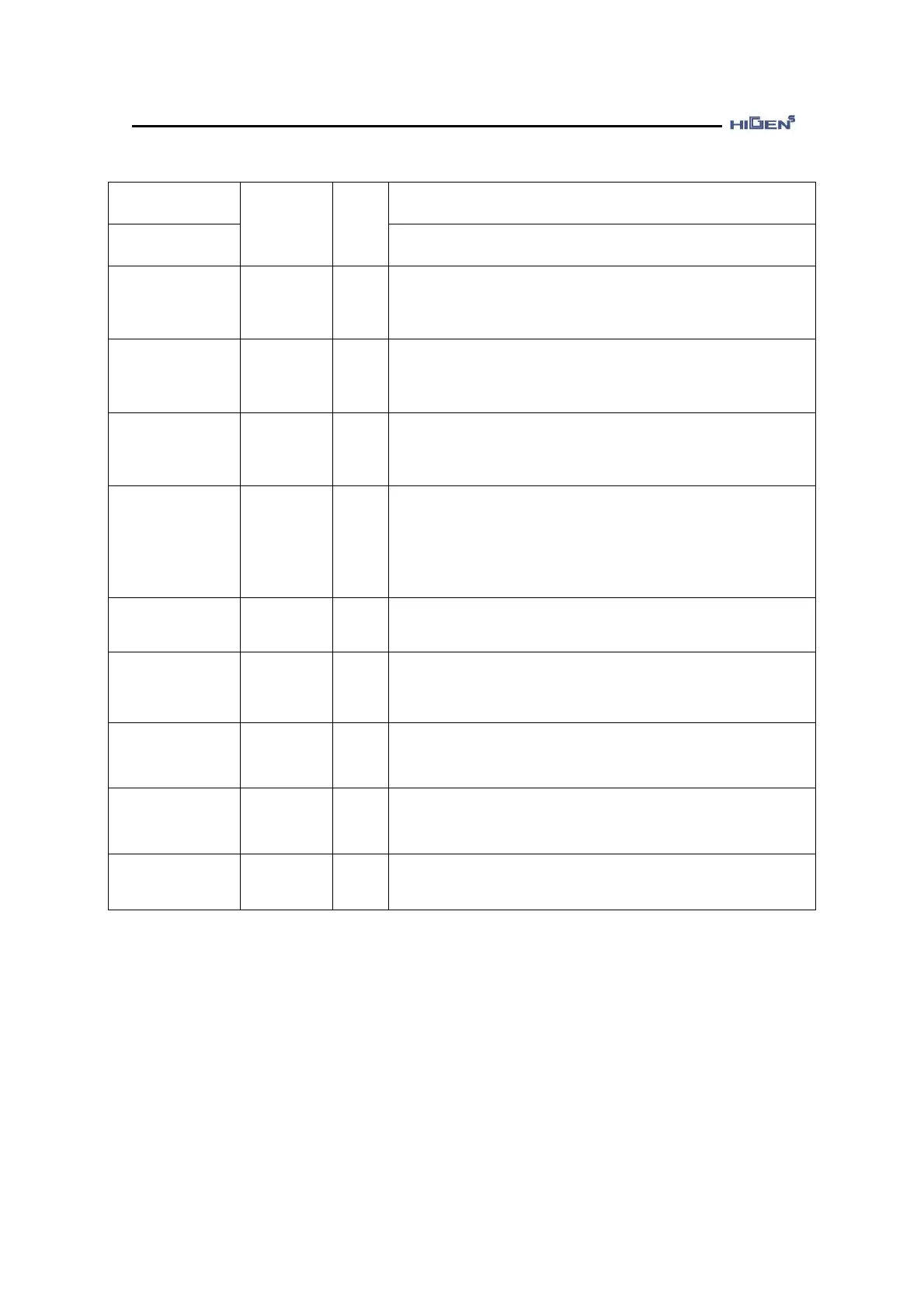

Analog torque

command

When operating in torque mode, enter the analog torque

command.

Analog torque

limit

TRQIN 28

When operating in speed mode, enter the torque limit.

Monitor output 1 MONIT1 3

Designated variable value is outputted in 0~±5[V] range

through the DA converter.

[Monitor selection] 0: Speed, 1: Speed command, 2: Torque,

3: Torque command, 4: Pulse, 5: Command pulse

Monitor output 2 MONIT2 2

Designated variable value is outputted in 0~±5[V] range

through the DA converter.

[Monitor selection] 0: Speed, 1: Speed command, 2: Torque,

3: Torque command, 4: Pulse, 5: Command pulse

Encoder output

PAO,/PAO

PBO,/PBO

PZO,/PZO

7,32

6,31

5,30

After dividing the motor encoder signal from CN2 as much

as the division rate set in the division setting menu, it

outputs in line drive method.

+24[V]

Power input

+24VIN 49

As the external I/O contact point power, enter

+24[VDC]±10% 1.0[A] or above for the external power.

(User preparation)

◆ When using the I/O contact point power simultaneously,

recalculate the power capacity according to the output

contact points.

+24[V] GND GND24

24

25

Connect the ground of power+24[VDC]±10% for external

I/O contact point. (User preparation)

0[V] GND

1,8

26,33

34,36

Common power ground terminal of speed, command,

torque limit command, speed, torque monitor output,

encoder output terminal.

Battery +

Battery -

BAT+

BAT-

29

4

When using the absolute encoder, connect the battery from

the host controller. Do not connect the drive side and both

sides of the host controller.

+12[V] output

-12[V] output

+12

-12

35

37

When simply outputting speed command and torque limit,

use the ±12[V] power.

FRAME

GROUND

FG 50 Ground the cable ground wire of CN1.

♥ Function of fixed I/O contact point cannot be changed.

Loading...

Loading...