4. Servo using method and gain adjustment

4-15

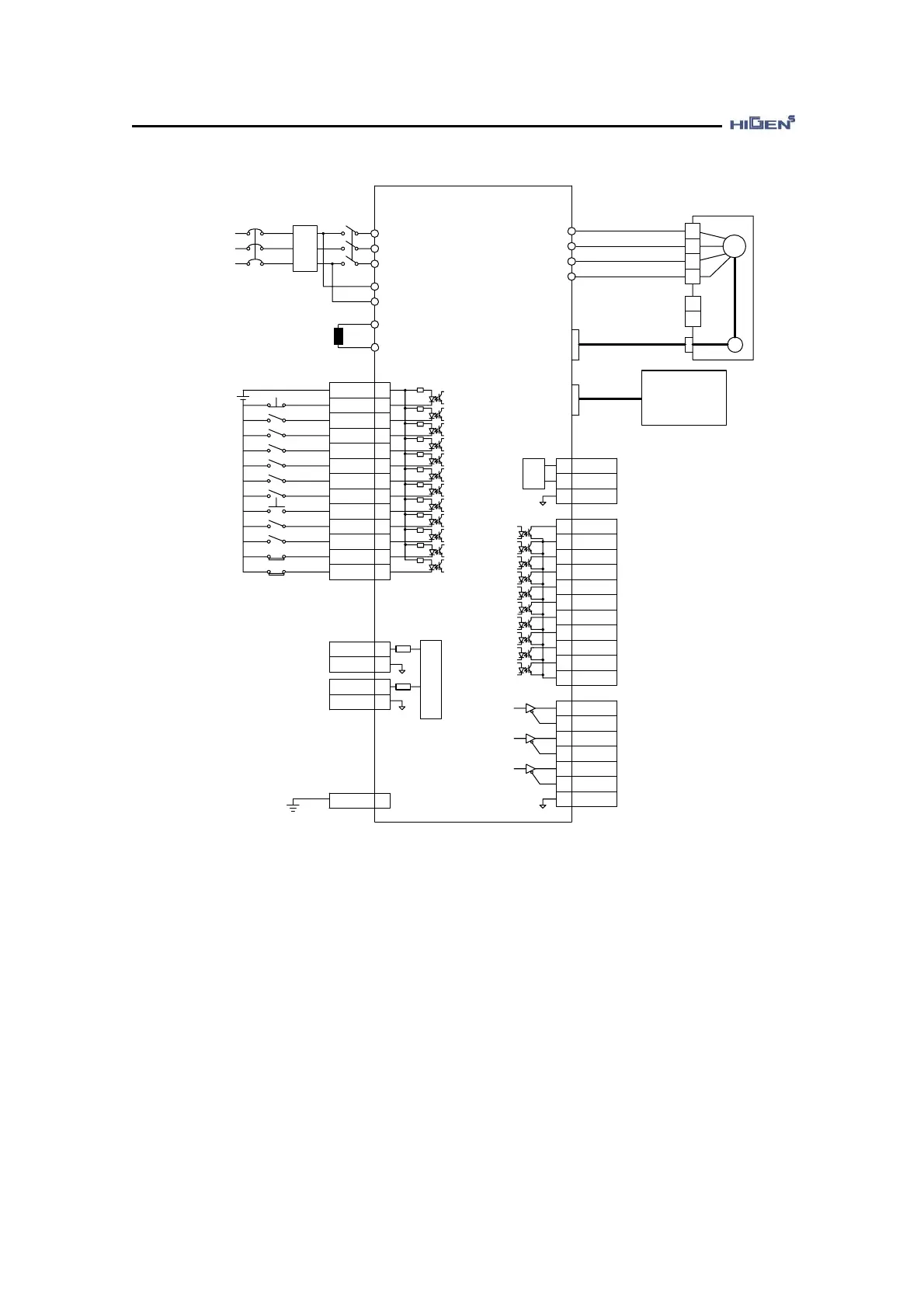

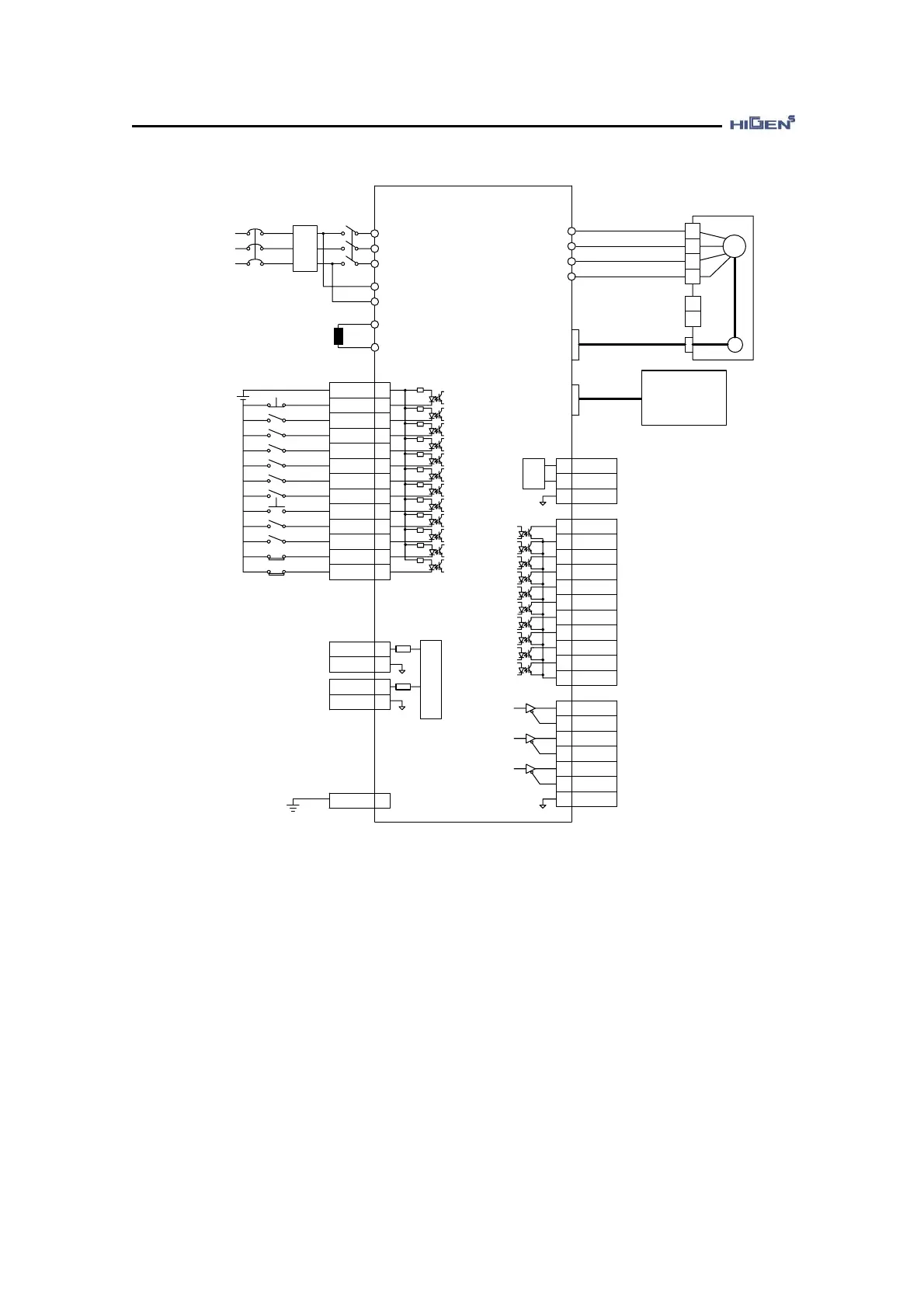

4.3.1 CN1 wiring diagram for torque control servo

Servo Drive

FDA7000

R

S

T

r

t

P

B

CN1

(input)

+24V

ESTOP

TRQ1

TRQ2

SPD1/

GEAR1

SPD2/

GEAR2

Not used

SVONEN

ALMRST

SPDLIM/

TLIM

DIR

CWLIM/

NTQLIM

CCWLIM/

PTQLIM

SPDIN

GND

TRQIN

GND

49

17

16

41

15

40

43

18

42

38

14

13

39

27

1

33

28

34

36

3.3K

+

-

+24V

U

V

W

FG

SM

+

-

Brake power

input terminal

U

V

W

FG

PG

CN2

CN3

MONIT1

MONIT2

GND

SVONOFF

INSPD/INP

OS/INTRQ

BRAKE

RDY

ZTRQ

SPDOUT/

TRQOUT

ALARM

PCWOUT/

PTQOUT

NCWOUT/

NTQOUT

Not used

GND24

PAO

/PAO

PBO

/PBO

PZO

/PZO

GND

3

2

8

26

23

47

48

22

19

21

46

20

45

44

24

25

7

32

6

31

5

30

8

26

CN1

(output)

A/D

D/A

NF

Power AC 200~230V

50/60Hz

NFB MC1

Regenerated

resistor

*Digital Loader

*PC Loader(RS232C)

*Network communication

(RS485, RS232C)

(note) 1

(note) 2

FG

50

(note) 4

(note) 3

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

3.3K

LPF

LPF

♥ The above input and output contact points are shown when setting the torque control mode contact point. (P07-

01,P08-01=25).

(Note) 1 : NF stands for Noise Filter and it must be used to prevent the noise from intruding from

the outside.

(Note) 2 : For the FDA7004/7004B~45 type, connect the single phase AC220V[V] to the r, t terminal,

auxiliary power. FDA7001~02 type does not have the auxiliary power r, t terminal.

(Note) 3 : The recovery resistances of FDA7004~FDA7010 are installed inside the driver as an

internal type. The recovery resistance of the FDA7001, 7002, 7004B, FDA7015 type or

above is the separately installed type. Check the capacity and apply accordingly.

(Note) 4 : Connect the ground wire of CN1 cable to the FG (Frame Ground) terminal.

(Note) 5 : Separate GND24 (CN – 24, 25) and GND (CN1 – 1, 8, 26, 33, 34, 36).

When connect commonness, malfunction of servo drive and burnout can occur.

Loading...

Loading...