28

6. Preparing the saw system for use

Planning the wire guidance system

■ Before installing the wire saw, you must carefully

study the situation and plan the wire guides, the drilling

of through-holes, the sequence of the work and the pro-

cedure involved. You must also plan the cooling water

supply and, if necessary, waste water disposal.

■ Consideration must be given to safety aspects and

cordoning off to prevent access by third parties etc.

■ Secure the area, plan the removal and transportation

of the sawn-out sections of the structure and all other

necessary measures.

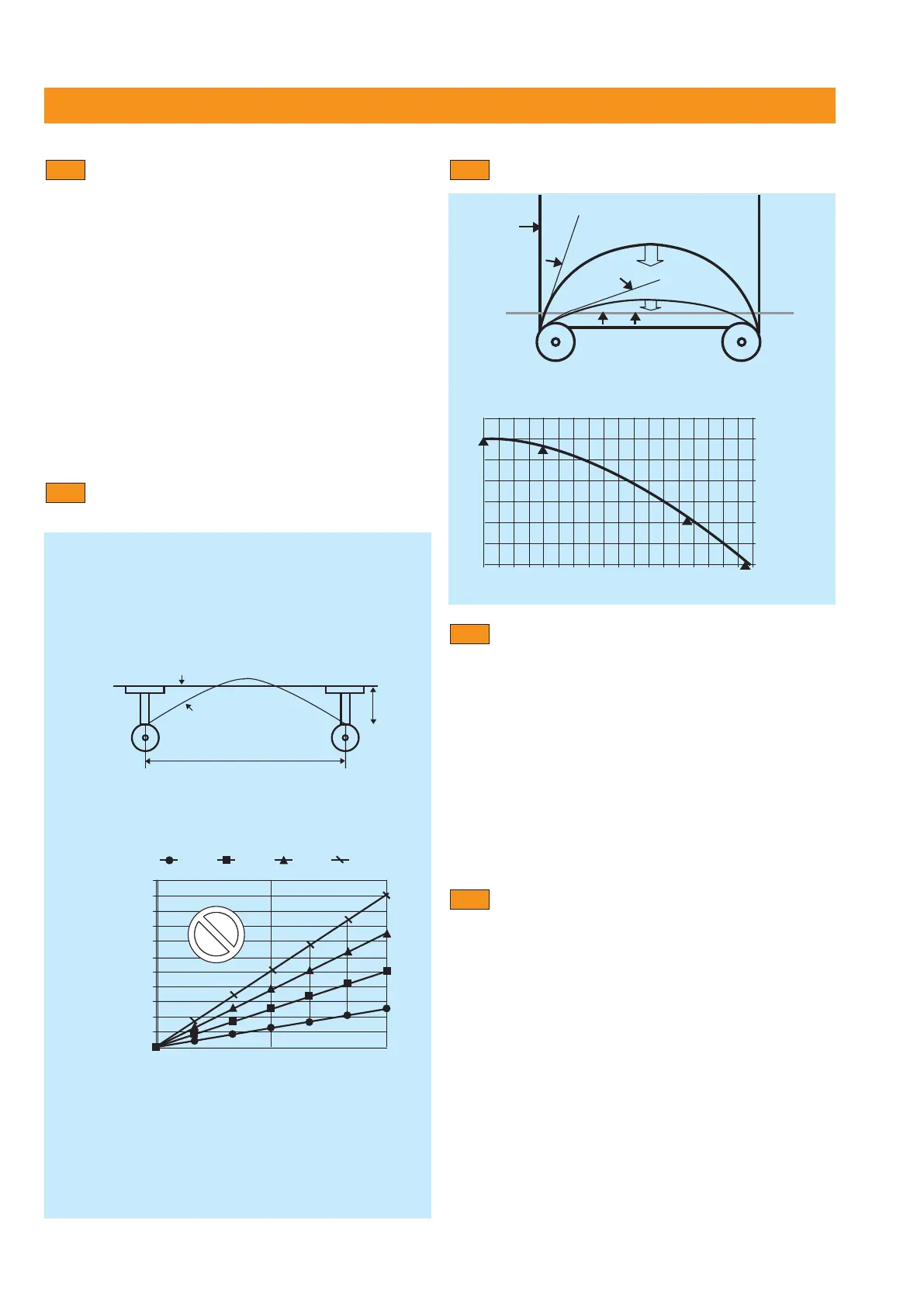

Positioning the wire guide pulleys

6.1

6.1.1

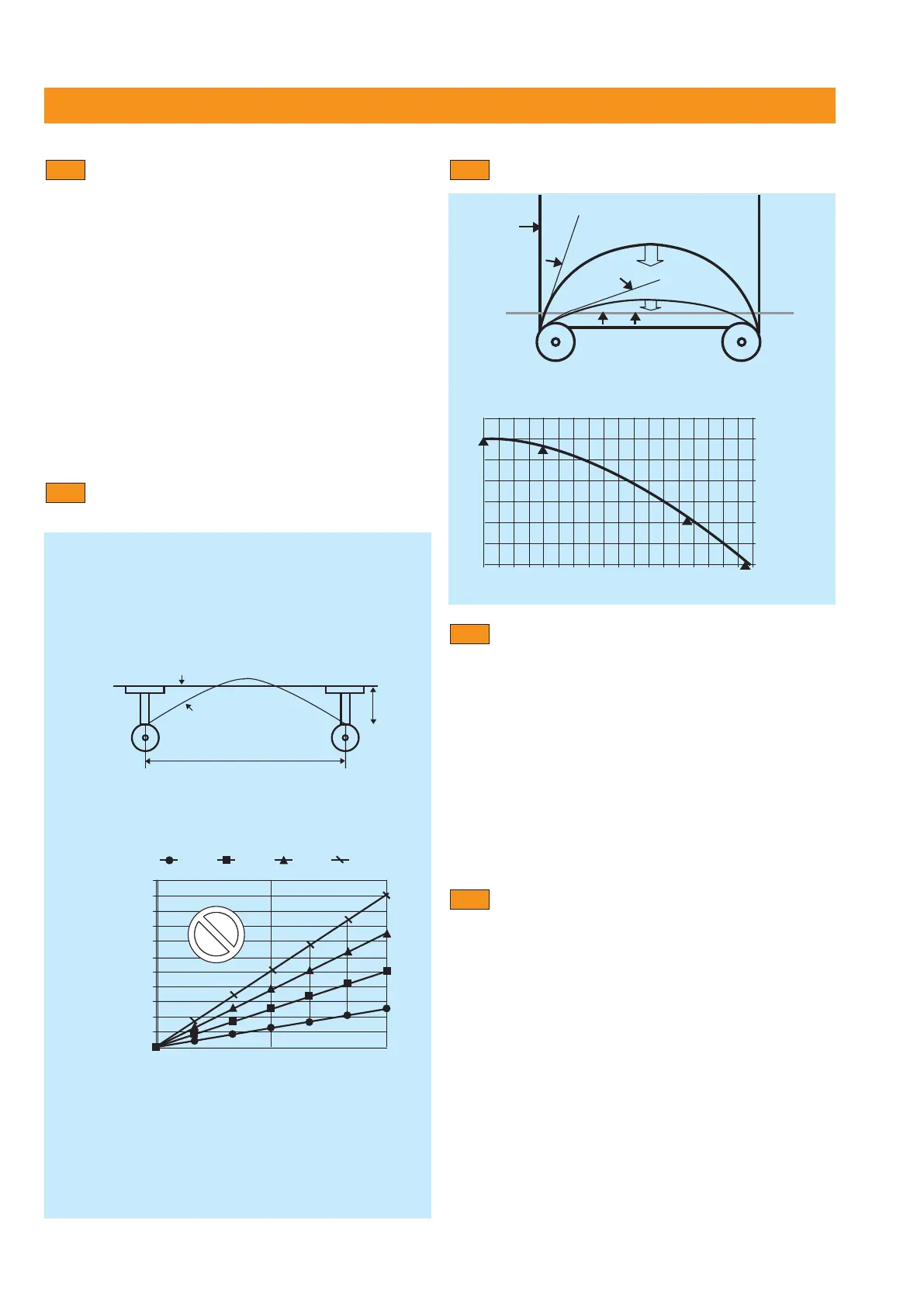

Drilling through-holes for the wire

■ According to the situation, the material to be cut and

the amount of reinforcement in the concrete, a hammer

drill and long masonry drill bits or a diamond coring

machine mounted on a stand can be used to drill through-

holes. Depending on the thickness of the section to be

cut and the material involved, we recommend drill bits

of 16 mm, 37 mm, 67 mm or 102 mm diameter.

■ Depending on the application, you will also require

accessories and special solutions for drilling to greater

depths.

Setting up the electric supply

NOTE

■ The DS WS15 wire saw will run even when the elec-

tric supply has only 4 conductors (1 earth/ground and

3 phases). However, the two 230 V supply sockets on

the control unit will provide no power if the neutral con-

ductor is missing. In this case it will be necessary to use

a separate 230 V supply cord for the compressor, lights

or a rotary hammer drill etc.

■ Ensure that the electric power supply has a fuse rat-

ing of at least 16 amps. A fuse rating of 32 amps is ide-

al. The jobsite power connection must be earthed/ground-

ed and equipped with a 30 mA ground fault circuit break-

er (PRCD). The earth connection and ground fault cir-

cuit breaker must be tested before the saw is operated.

6.2

6.3

Loading...

Loading...