35

6. Preparing the saw system for use

2

nd

step

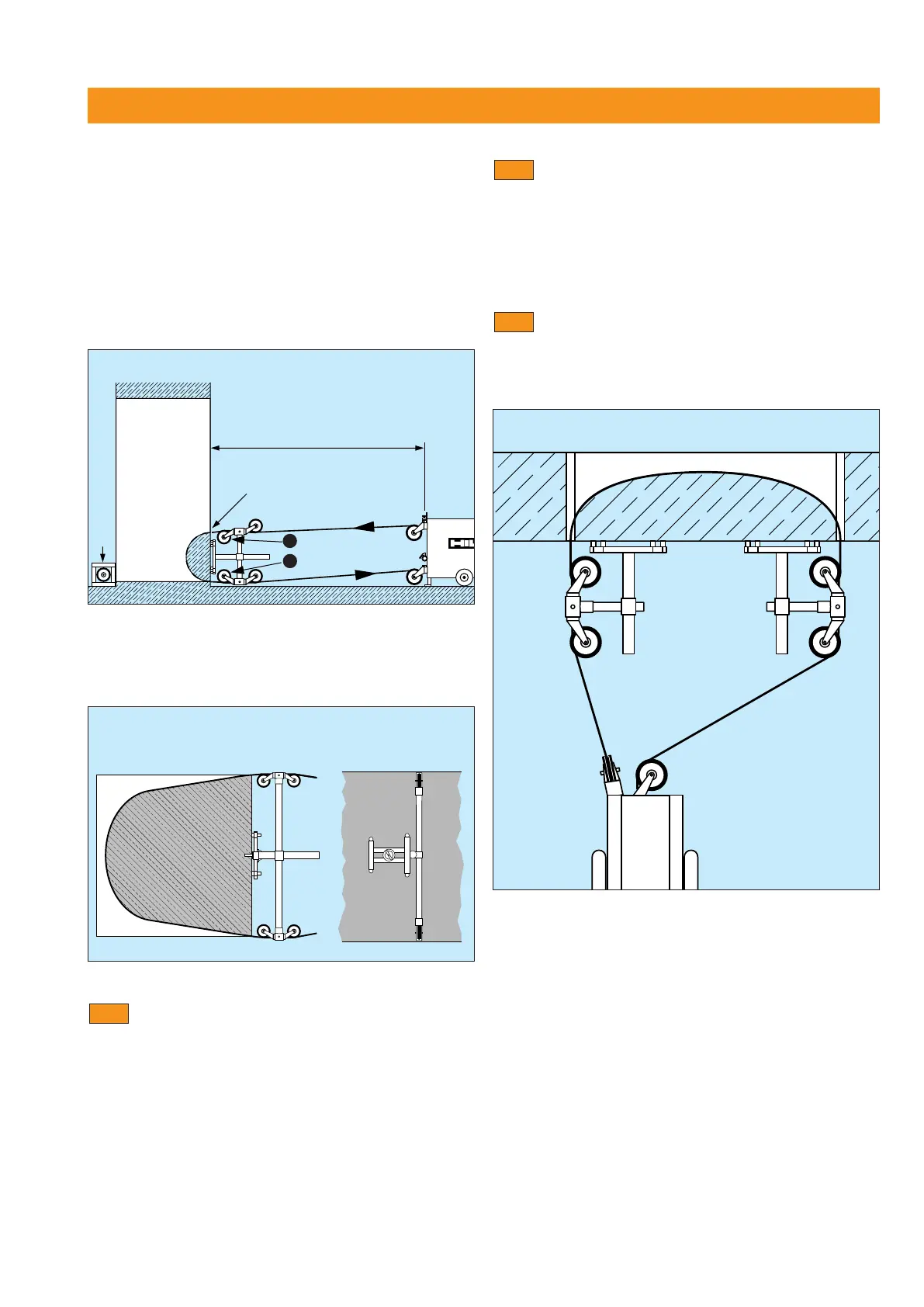

■ Disengage the wire from the release pulley when the

cut is approx. 50% complete, i.e. the wire then also begins

to cut from below.

■ Provided the operator remains outside the danger

zone, this can be done while sawing continues by means

of a long string: simply pull out the bolt from the release

pulley!

Water

Release pulley

■ The wire is caught by pulleys

and

when it

escapes from the kerf at the end of the cut.

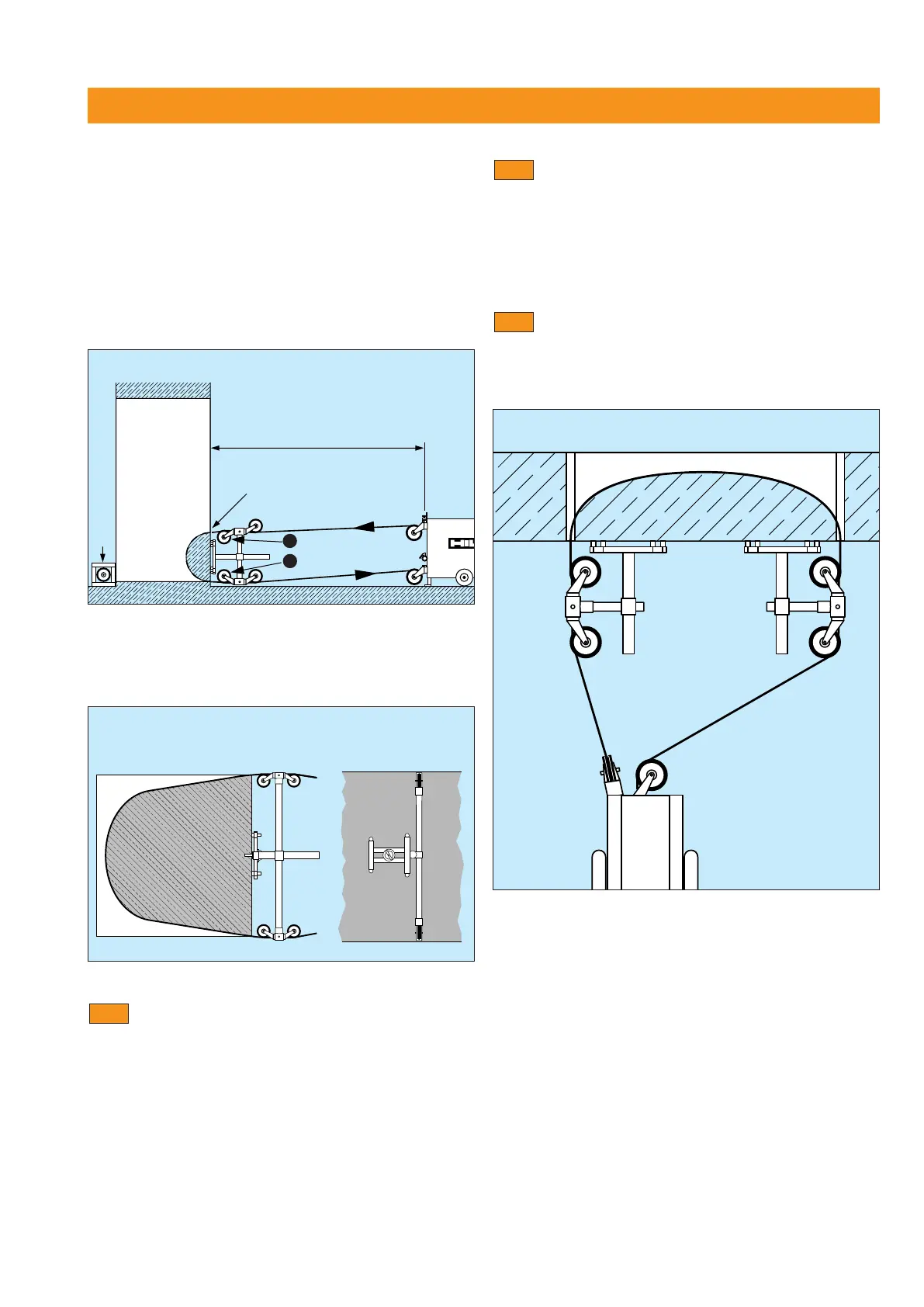

Example: Using a double-pair pulley stand for a

vertical cut through a concrete component

Distance “D” between the drive and object

being cut

■ The distance “D” between the drive unit and the object

being cut is determined by the application. The ideal dis-

tance, i.e. the “free wire length”, is approximately 2–3

m, but it can also easily reach 5–10 m. However, for even

greater distances, the wire must run over an additional

pulley stand. The distance “D” (or "free wire length”)

should always be kept as short as possible for safety

reasons.

6.9.3

Optimum length of cut “L”

■ The optimum length of cut “L”, i.e. the wire length

effectively involved in the cutting process, ranges from

approximately 2 to 8 m for the DS WS15 wire saw. This

enables the operator to achieve the greatest efficiency,

and also ensures good service life of the wire.

Standard horizontal cut

■ Position the drive unit at a short distance from the

object to be cut, with the tension side facing the object.

6.9.5

6.9.4

Loading...

Loading...