11

2. Description

Drive principle

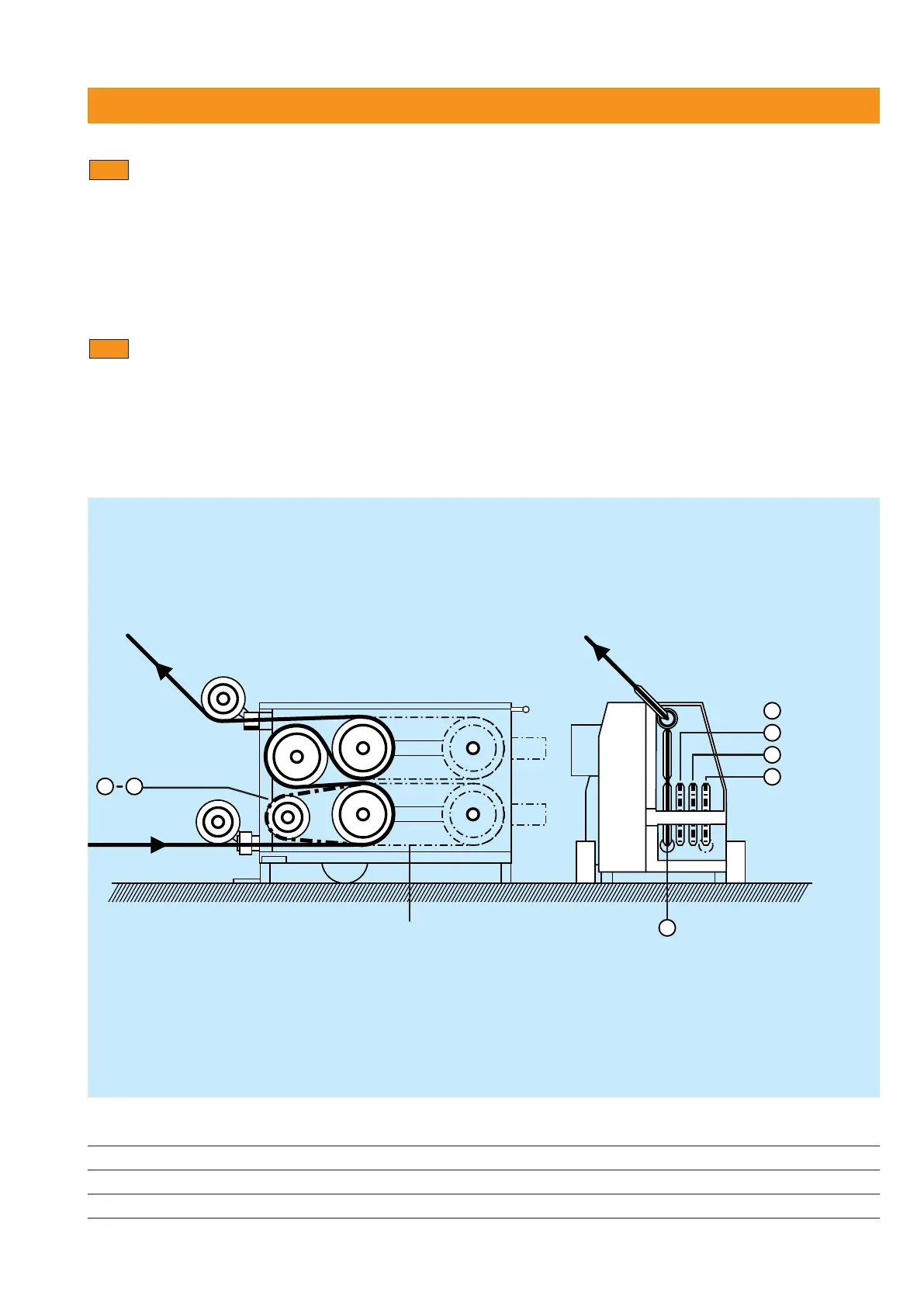

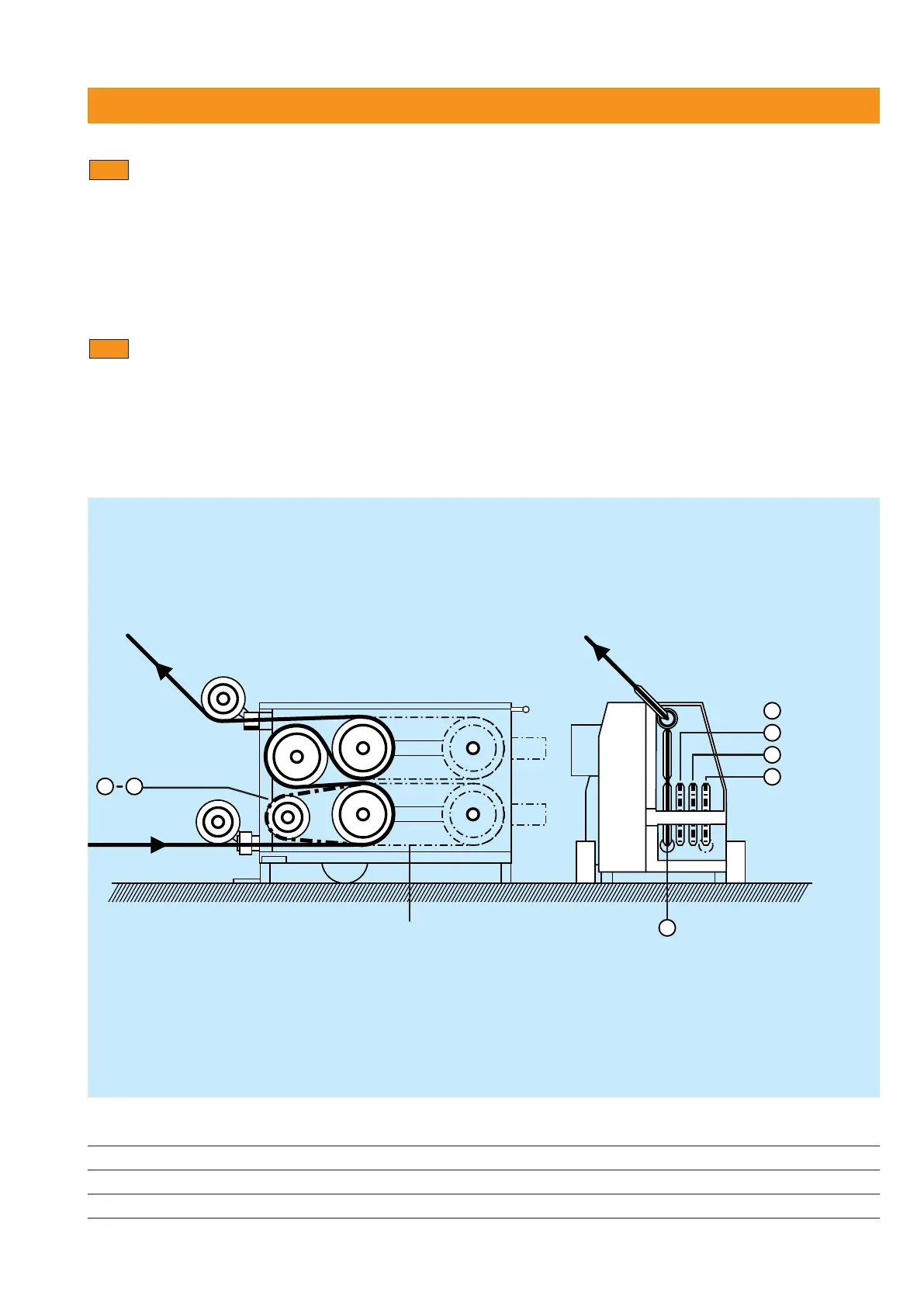

The wire is driven by 2 electric motors fitted with drive

wheels. The diamond wire is fed around the drive wheels

in the form of a figure eight to ensure optimum grip. The

motors’ performance characteristics and control sys-

2.4

Saw advance and wire storage

The wire advance operates according to the principle of

a block and tackle working in reverse. The advance move-

ment, causing the wire to be drawn in, is effected by two

compressed air cylinders working in opposing direc-

2.5

tem are designed to achieve high initial torque and work-

ing torque.

The wire speed can be infinitely adjusted within the

0–27 m/s range.

tions. Accordingly, the rear pulleys (storage pulleys,

280 mm dia.) are mounted on a moving carriage. The

maximum wire storage capacity is 9.2 m. The minimum

length of wire required by the drive system is 3.2 m.

Wire capacity Wire in drive Wire storage Material thickness

Basic capacity length 3.2 m 2 m per stroke 1 m

1 storage pulley length 4.6 m 2.4 m per stroke 1.9 m

Full capacity length 7.4 m 4.8 m per stroke 4.5 m

Loading...

Loading...