MAINTENANCE

3-10

VALVE CLEARANCE

INSPECTION

• After the valve clearance inspection, check the

engine idle speed (page 5-78).

• Inspect and adjust the valve clearance while the

engine is cold (below 35°C/95°F).

FRONT:

Remove the cylinder head cover (page 8-6).

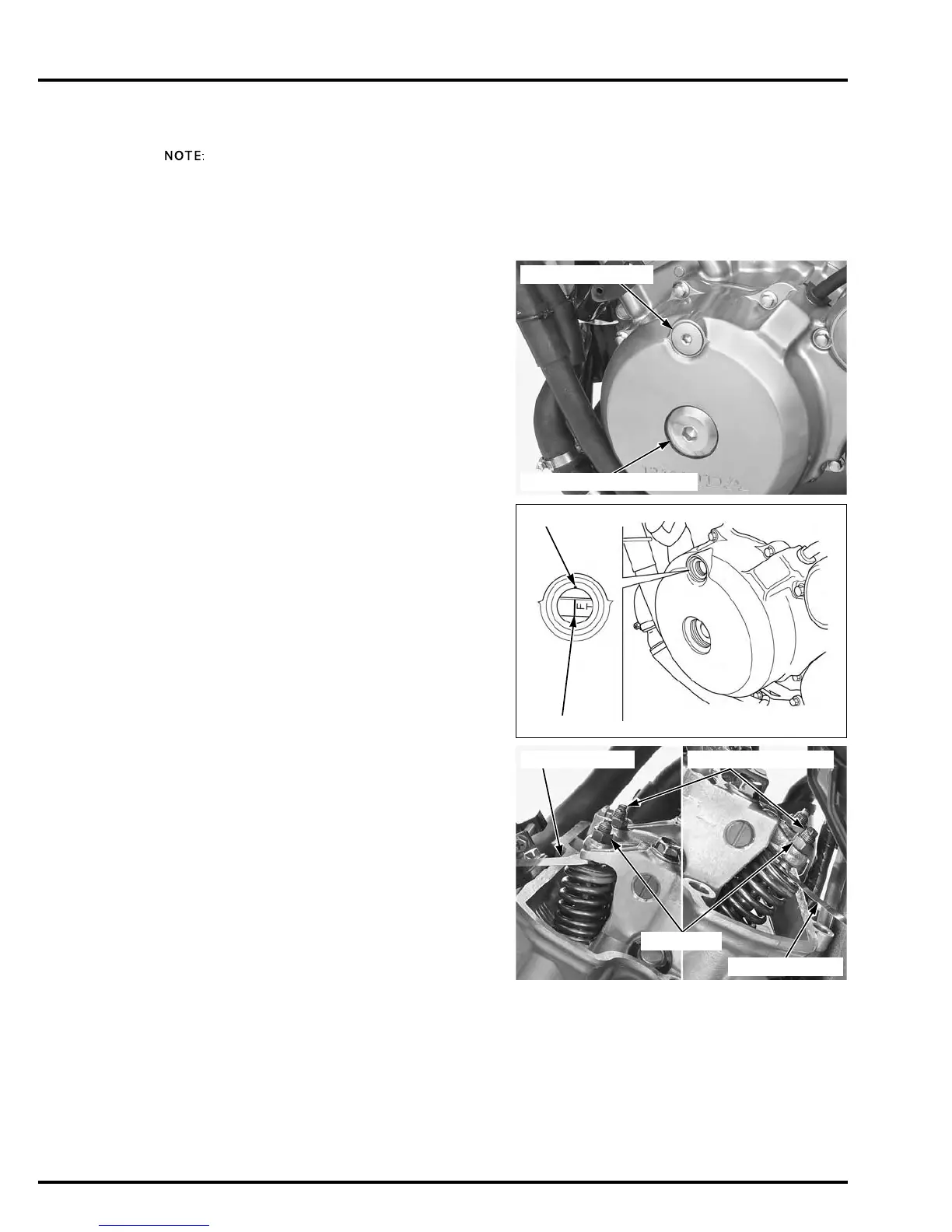

Remove the timing and crankshaft hole caps.

Rotate the crankshaft counterclockwise and align

the "FT" mark on the flywheel with the index notch

on the left crankcase cover.

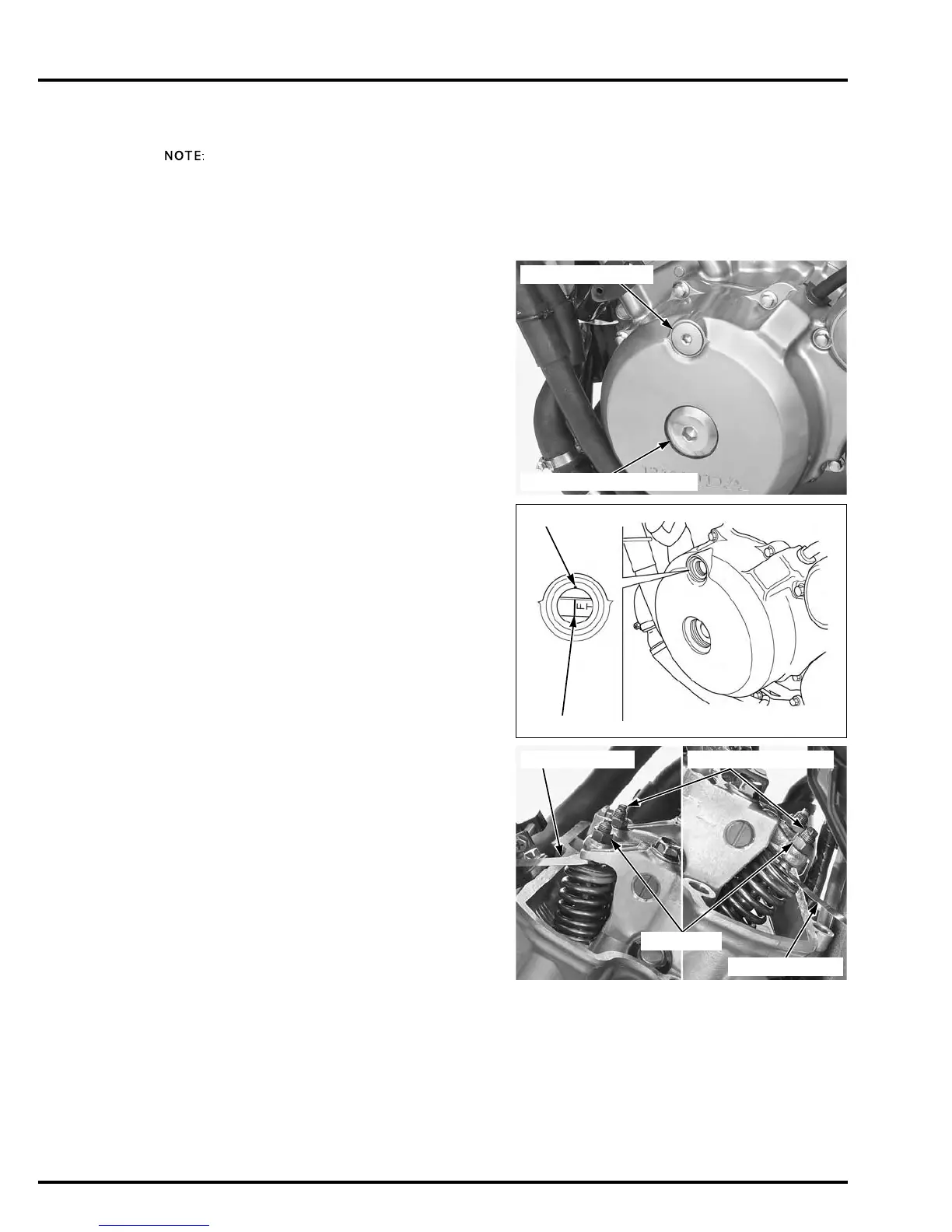

Make sure the piston is at TDC (Top Dead Center) on

the compression stroke.

This position can be obtained by confirming that

there is slack in the rocker arms. If there is no slack,

rotate the crankshaft counterclockwise one full turn

and align the "FT" mark with the index notch again.

When checking the

clearance, slide the

feeler gauge from

the center toward

the outside.

Check the valve clearances by inserting a feeler

gauge between the adjusting screw and valve stem.

CRANKSHAFT HOLE CAP

TIMING HOLE CAP

VALVE CLEARANCES:

IN: 0.15 ± 0.02 mm (0.006 ± 0.001 in)

EX: 0.20 ± 0.02 mm (0.008 ± 0.001 in)

FEELER GAUGE ADJUSTING SCREW

LOCK NUT

FEELER GAUGE

Loading...

Loading...