CHAPTER 7: OPTIONAL COMPONENTS

37 63-4528—04

*

The longest operation time for 10% ED is 10 sec. (on: 10 sec.; off: 90 sec.)

**

See Brake Performance Curve below for the relation between Running Time, ED(%) vs Braking Current.

***

The calculation of the maximum braking torque is based on a 4-pole motor (1800rpm)

****

For the heat dissipation, a resistor of 400W or lower should be fixed to the frame and keep the surface below 250° C (400° F).

As for a resistor of 1000W and above, the surface temperature should be kept below 600

° C. If the temperature is over the

resistor’s temperature limit, it will be necessary to add heat dissipating system or increase resistor’s power

NOTE:

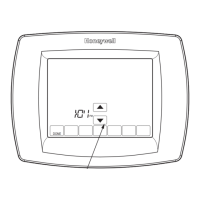

1. Definition for Brake Usage ED%

Explanation: The definition of the brake usage ED (%) is for assurance of enough time for the brake unit and brake resistor

to dissipate away heat generated by braking. When the brake resistor heats up, the resistance would increase with temper-

ature, and brake torque would decrease accordingly. Recommended cycle time is one minute.

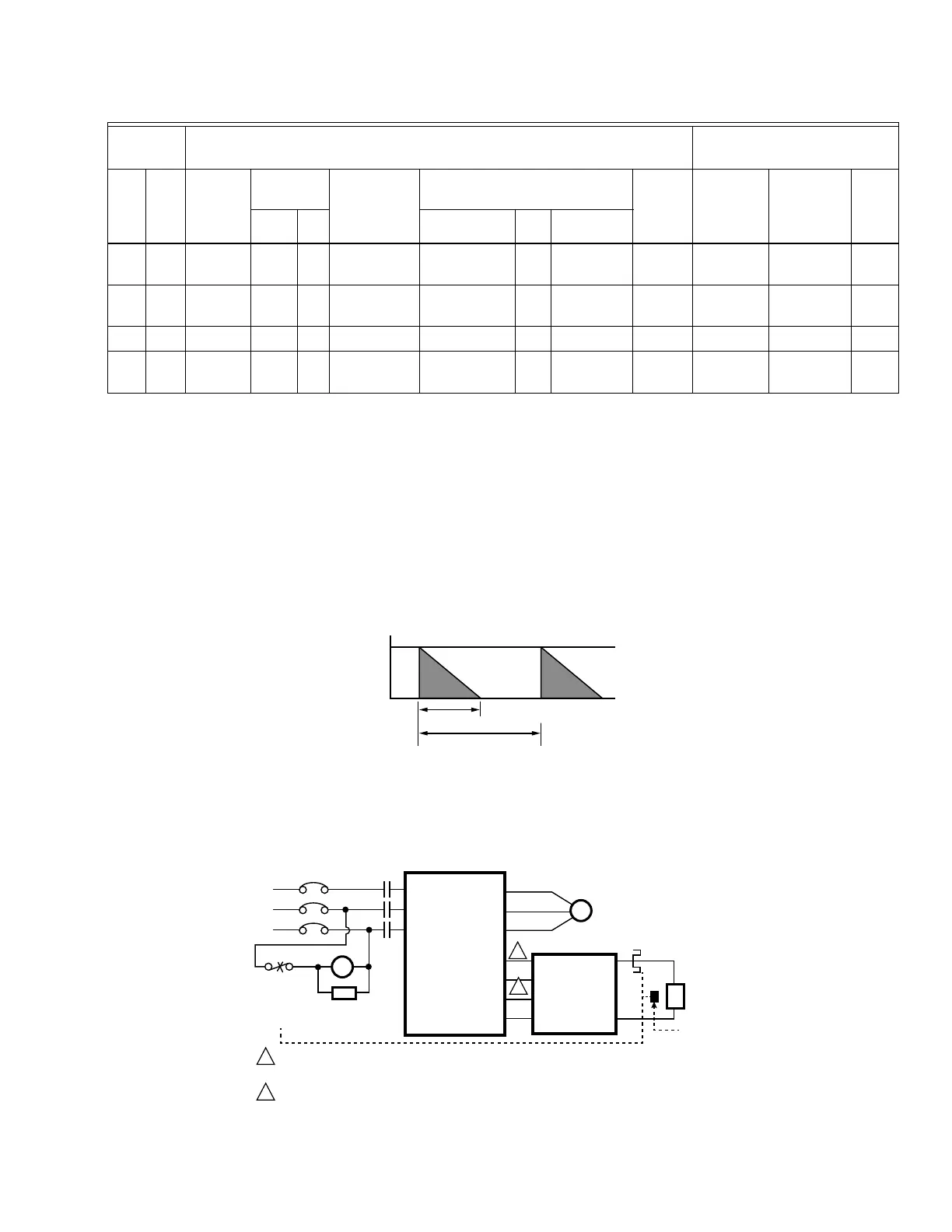

For safety concern, install an overload relay (O.L) between the brake unit and the brake resistor together with the magnetic

contactor (MC) prior to the drive to protect the drive from abnormal functions. The purpose of installing the thermal over-

load relay is to protect the brake resistor from damages due to frequent brakes, or caused by brake unit’s continuous

conductions resulted from unusual high input voltage. Under such circumstance, turn off the power to prevent damaging the

brake resistor.

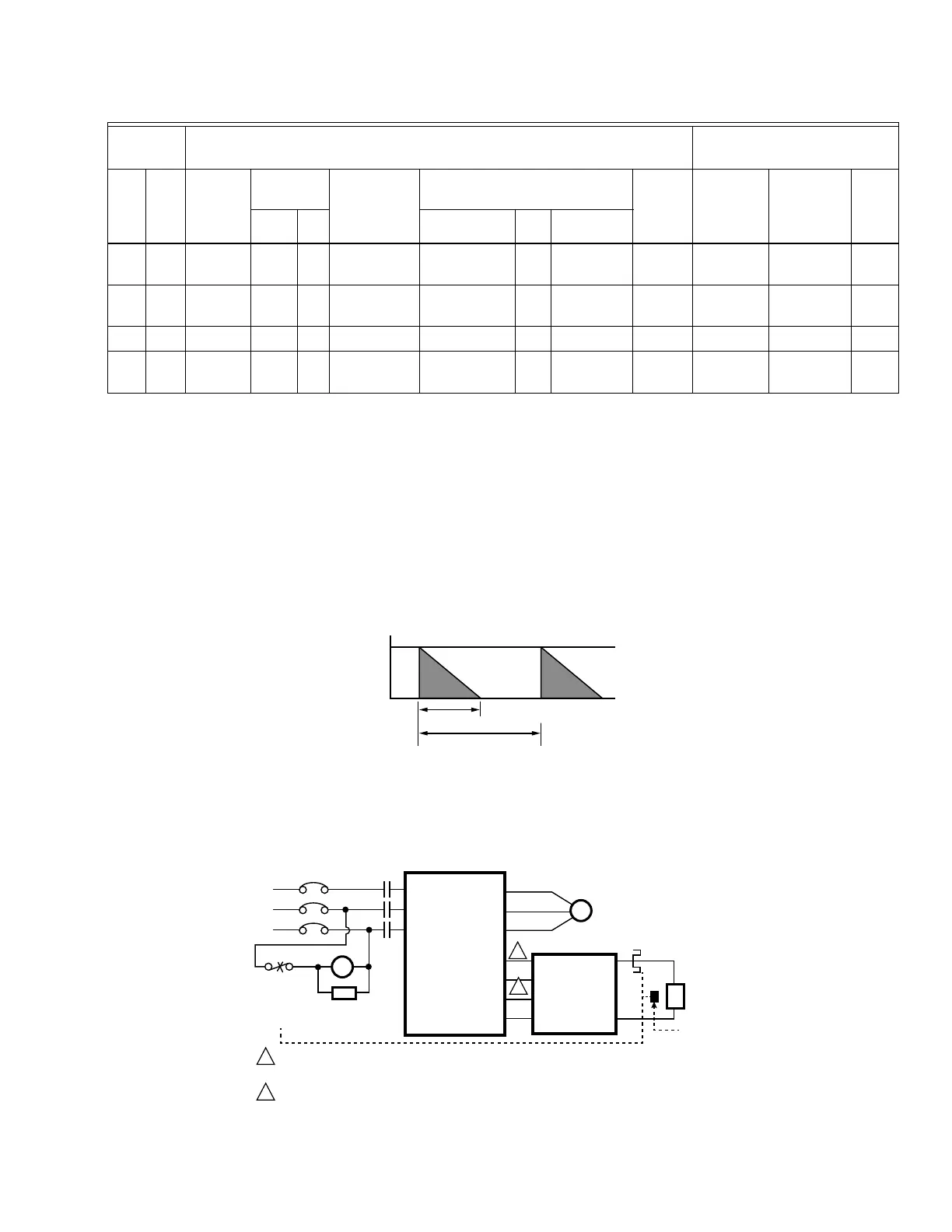

60 45 25.1 4045 1

4800W 15Ω

BR1K2W015 4

2 parallel,

2 series

50 12.7 60 45.6

75 55 30.5 4045 1

6000W 13Ω

BR1K5W013 4

2 parallel,

2 series

59 12.7 60 45.6

100 75 37.2 4030 2

8000W 10.2Ω

BR1K0W5P1 4 4 series 76 9.5 80 60.8

125 90 50.8 4045 2

9600W 7.5Ω

BR1K2W015 4

2 parallel,

2 series

100 6.3 120 91.2

Table 1. 230V & 460V

Applicable

Motors

10% ED

*

Max. Braking Torque

**

HP kW

Braking

Torque

(kg-m)***

Brake Unit

Resistor

Value Spec.

for Each

VFD

Braking Resistor Series for

Each Brake Unit

Total

Braking

Current

Min.

Resistor

Value (Ω)

Max. Total

Braking

Current (A)

Peak

Power

(kW)

VFDB Unit

Part #****

Unit Connection

CYCLE TIME

BRAKE TIME

T

100%

T0

ED% T1/T0 X 100

M33296

M33297

R/L1

S/L2

T/L3

R/L1

S/L2

T/L3

NFB

MC

O. L.

SA

MC

U/T1

V/T2

W/T3

VFD

SERIES

DCM

E.F.

-

(N)

+ (P)

RC

RA

-

(N)

+ (P)

B1

B2

IM

O. L.

BR

MOTOR

SURGE

ABSORBER

THERMAL

OVERLOAD

RELAY OR

TEMPERATURE

SWITCH

VFDB

BRAKING

THERMAL

OVERLOAD

RELAY

BRAKING

RESISTOR

TEMPERATURE

SWITCH

1

2

WHEN USING THE VFD WITH DC REACTOR, PLEASE REFER TO WIRING DIAGRAM IN THE VFD

USER MANUAL FOR THE WIRING OF TERMINAL

+(P) OF BRAKING UNIT.

DO NOT WIRE TERMINAL

-

(N) TO THE NEUTRAL POINT OF POWER SYSTEM.

2

1

Loading...

Loading...