Section

V

P~ag~aphs 5-36 to 5-50

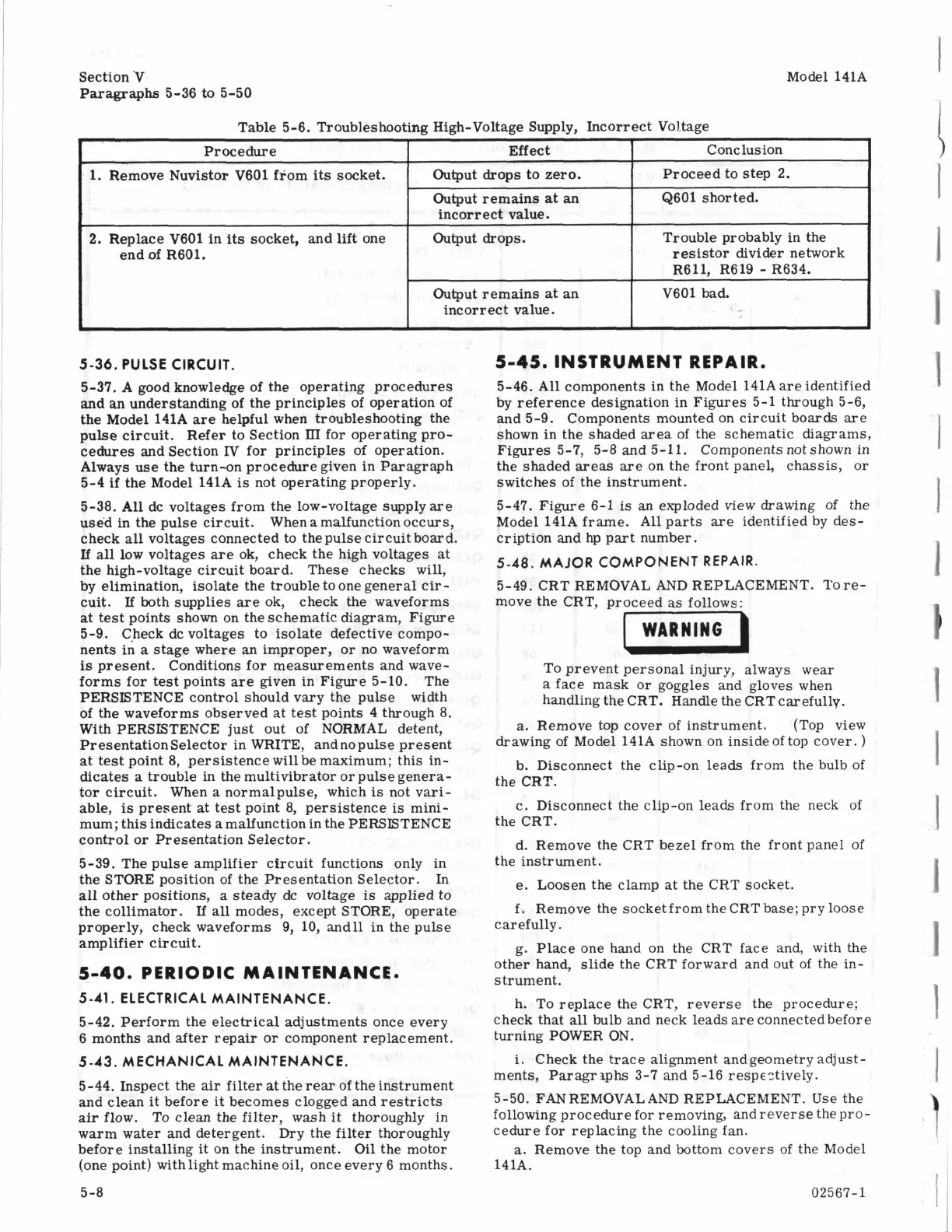

Procedure

1.

Remove Nuvistor V601 from

its

socket.

2.

Replace V601 in

its

socket, and

lift

one

end

of

R601.

Model

141A

1

Effect Conclusion

Output

drops

to zero.

Output remains

at

an

incorrect value.

Output drops.

Proceed to step

2.

Q601 shorted.

Trouble probably in the

resistor divider network

R611, R619

-

R634.

Output remains

at

an

V601 bad.

incorrect value.

5-36.

PULSE CIRCUIT.

5-37.

A

good

knowledge of the operating procedures

and

an

understanding of the principles of operation of

the Model

141A

are helpful when troubleshooting the

pulse circuit. Refer to Section

Ill

for operating pro-

cedures and Section

IV

for principles of operation.

Always use the turn-on procedure given in Paragraph

5-4

if

the Model 141A

is

not operating properly.

5-38. All dc voltages from the low-voltage supply

are

used in the pulse circuit. When a malfunction occurs,

check

all

voltages connected to thepulse circuit board.

If

all

low voltages are ok, check the high voltages at

the high-voltage circuit board. These checks will,

by elimination, isolate the trouble to one general cir

-

cuit.

If

both supplies

are

ok,

check the waveforms

at

test points shown on the schematic diagram, Figure

5-9. Check dc voltages to isolate defective compo-

nents in

a

stage where an improper,

or

no waveform

is

present. Conditions for measurements and wave-

forms for test points are given in Figure 5-10. The

PERSISTENCE control should vary the pulse width

of the waveforms observed at test points 4 through

8.

With PERSISTENCE just out of NORMAL detent,

PresentationSelector in

WRITE,

andnopulse present

at

test point

8,

persistence will be maximum; this in-

dicates

a

trouble in the multivibrator or pulse genera-

tor circuit. When

a

normalpulse, which

is

not vari-

able,

is

present at test point

8,

persistence

is

mini-

mum; this indicates

a

malfunction in the PERSISTENCE

control or Presentation Selector.

5-39. The pulse amplifier circuit functions only in

the STORE position of the Presentation Selector.

In

all

other positions,

a

steady dc voltage is applied to

the collimator.

If

all

modes, except STORE, operate

properly, check waveforms 9,

10,

and11 in the pulse

amplifier circuit.

5-40.

PERIODIC MAINTENANCE.

5-41.

ELECTRICAL MAINTENANCE.

5-42. Perform the electrical adjustments once every

6 months and after repair

or

component replacement.

5-43.

MECHANICAL MAINTENANCE.

5-44. Inspect the

air

filter

at

the

rear

of the instrument

and clean

it

before

it

becomes clogged and restricts

air

flow.

To

clean the filter, wash it thoroughly in

warm water and detergent. Dry the filter thoroughly

before installing it on the instrument. Oil the motor

(one point) with light machine oil, once every

6

months.

5-8

5-45.

INSTRUMENT REPAIR.

5-46.

All

components in the Model 141Aare identified

by reference designation in Figures 5-1 through 5-6,

and 5-9. Components mounted on circuit boards are

shown in the shaded area of the schematic diagrams,

Figures 5-7, 5-8 and 5-11. Components notshown in

the shaded

areas

are on the front panel, chassis,

or

switches of the instrument.

5-47. Figure 6-1 is

an

exploded

view

drawing of the

Model 141A frame.

All

parts are identified by des-

cription and hp part number.

5-48.

MAJOR

COMPONENT REPAIR.

5-49. CRT REMOVAL

AND

REPLACEMENT. Tore-

move the CRT, proceed as follows:

pGi-1

TO prevent personal injury, always wear

a face mask

or

goggles and gloves when

handling the CRT. Handle the CRT carefully.

a. Remove top cover of instrument. (Top view

drawing of Model

141A

shown on inside of top cover.

)

b. Disconnect the clip-on leads from the bulb of

the CRT.

c. Disconnect the clip-on leads from the neck of

the CRT.

d. Remove the CRT bezel from the front panel of

the instrument.

e.

Loosen the clamp at the CRT socket.

f.

Remove the socket from the CRT base; pry loose

carefully.

g. Place one hand on the CRT face and, with the

other hand, slide the CRT forward and out of the in-

strument.

h. To replace the CRT, reverse the procedure;

check that all bulb and neck leads are connected before

turning POWER ON.

i.

Check the trace alignment andgeometry adjust-

ments, Paragraphs 3-7 and 5-16 respeztively.

5-50. FANREMOVALAND REPLACEMENT. Use the

following procedure for removing, and reverse thepro-

cedure for replacing the cooling fan.

a.

Remove the top and bottom covers of the Model

141A.

02567-1

I

1

I

I

1

1

1

I

!

1

1

1

I

1

1

I

1

1

I

I

I

I

Loading...

Loading...