Model

5528A

Straightn

ess

and Squareness Con

si

derations

21·8

l

..

-.

.1

\

..-\

0,

\

\

\

,

'0-

-

-

-

-

-

i

-

-

0,

t

-

-

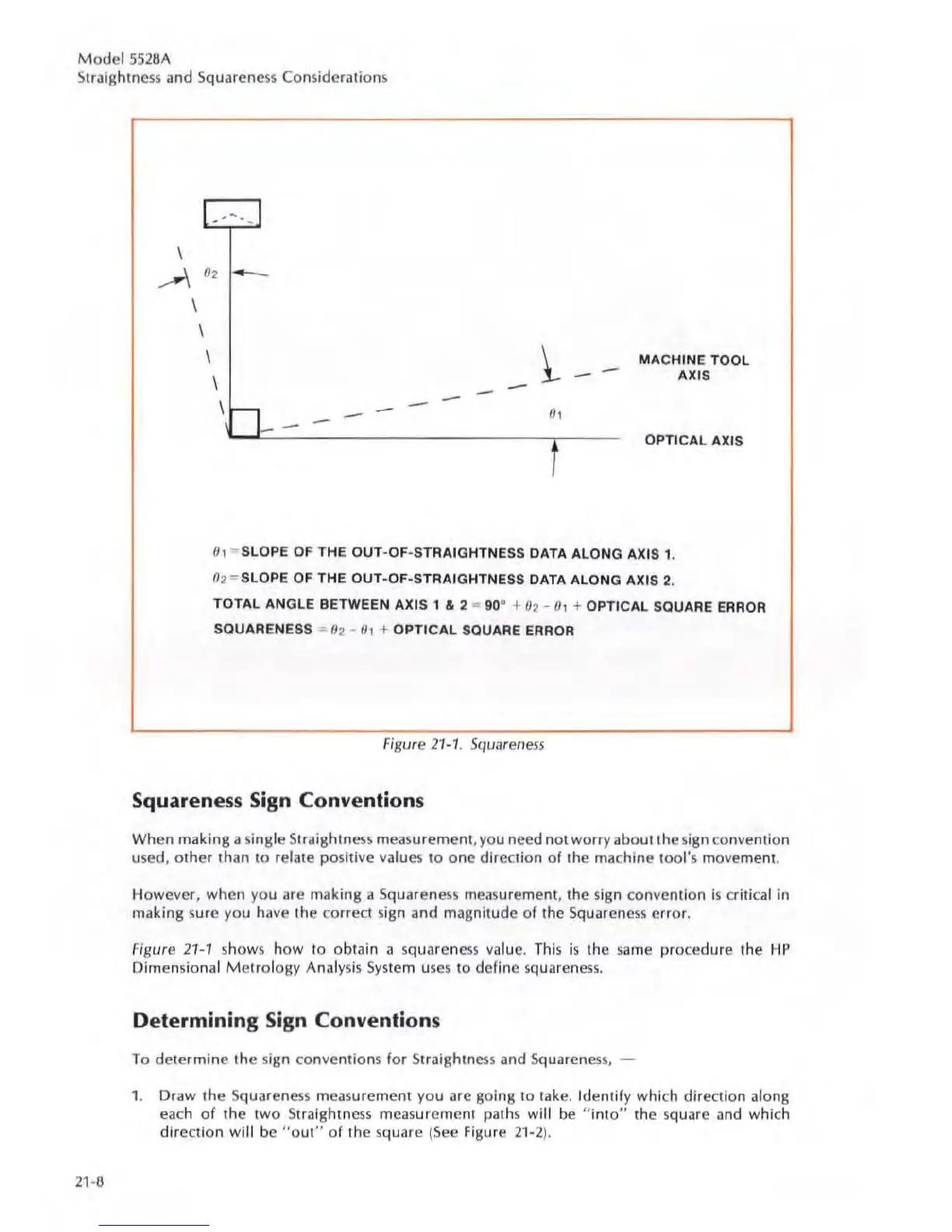

MACHINE TOOL

AXtS

OPTICAL AXIS

0,

- SLOPE

OF

THE

OUT

-OF-STRAIGHTNESS DATA ALONG AXIS 1.

0

2"'"

SLOPE OF THE

OUT·

OF-STRAIGHTNESS DATA ALONG AXIS 2.

TOTAL ANGLE BETWEEN AXtS 1 & 2 -

go

a +

02

-

0,

+ OPTICAL SQUARE ERROR

SQUARENESS -

82

- 0, +

OPTICAL

SQUARE ERROR

Figure

21

·

1,

Squareness

Squareness Sign Conventions

When making a single Straightness m

easu

rement, you need

not

wo

rry about the sign convention

used, o ther than

to

relate

po

sitive values

to

one d

ir

ection

of

the machine

too

l

's

mo

ve

ment.

However,

whe

n you are making a Squareness

measu

rement. the sign convention

is

criti

ca

l

in

making sure you have the correct sign and magnitude of the Squarcness erro

r.

Figure

21-1

shows h

ow

10

ob

t

ai

n a squaren

ess

va

lu

e.

This

is

the

sa

me procedure the

HP

Dimen

sional

Metrology

Anal

ys

is System

uses

to

define

squa

ren

ess.

Determining Sign Conventions

To

determine

Ih

e sign

co

nvention

s

for

St

ra

ightn

ess

and

Squa

ren

ess,

1.

Draw

the Squar

eness

measurement you are going to take. Identify

whic

h direction along

each

of

the

two

Straightness measurcment paths will be

"into"

the square and which

direction

wil

l be "O

UI

"

of

the

sq

uare (

See

Figu re 21·2

).

Loading...

Loading...