Mode

l

5528A

Appendi

x A: Principles of

Operation

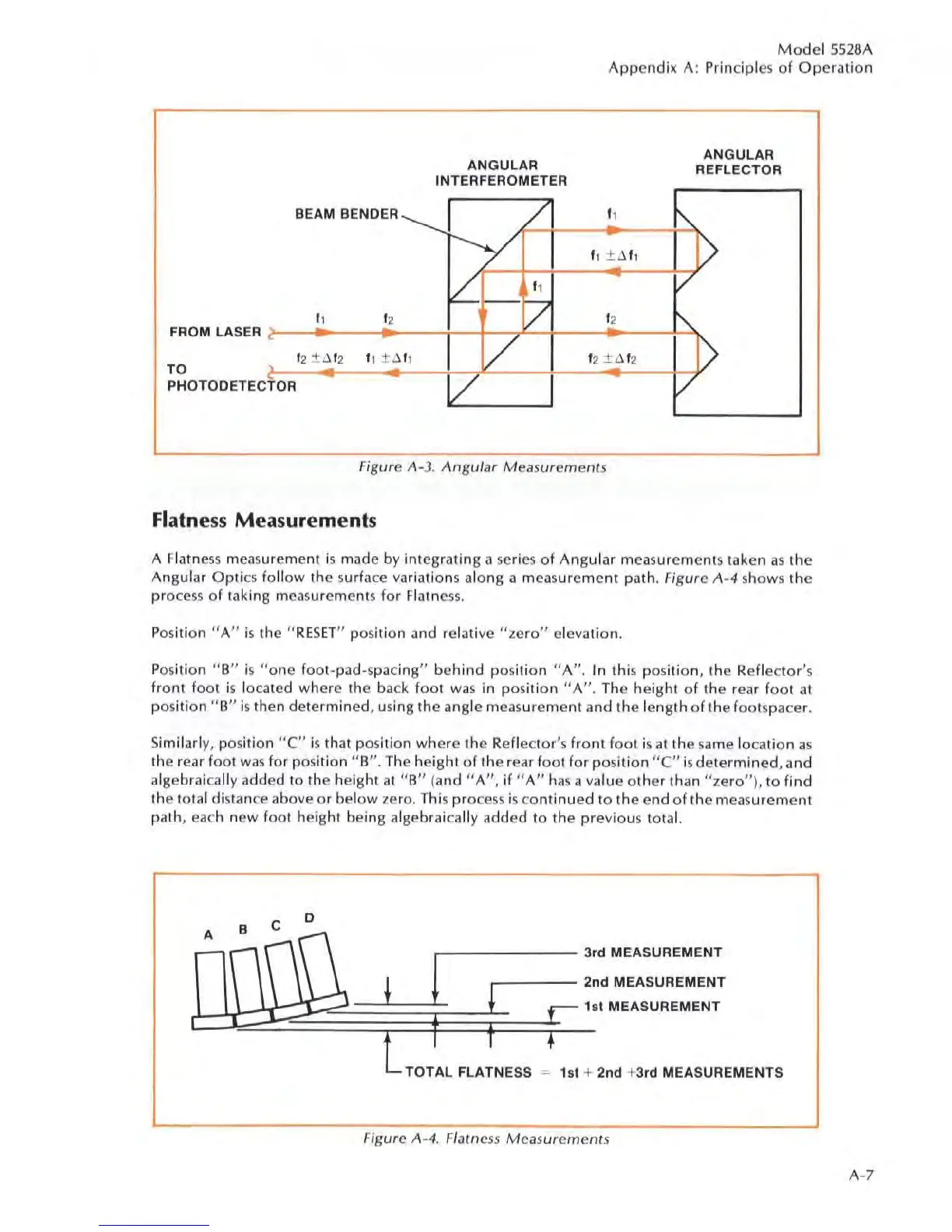

ANGULAR

INTERFEROMETER

ANGULAR

REFLECTOR

BEAM BENDER

-------.

/

"

"-

IY

~

fl

±

~f1

1/

"

/

.,

"

/

"

"-

FROM LASER

V

~

'2

±.1

'2

'1

±~

'

1

f2

±M 2

TO

PHOTO DETECTOR

1/

/

Figure A-3.

An

gu

lar Mea5l/fcmcnls

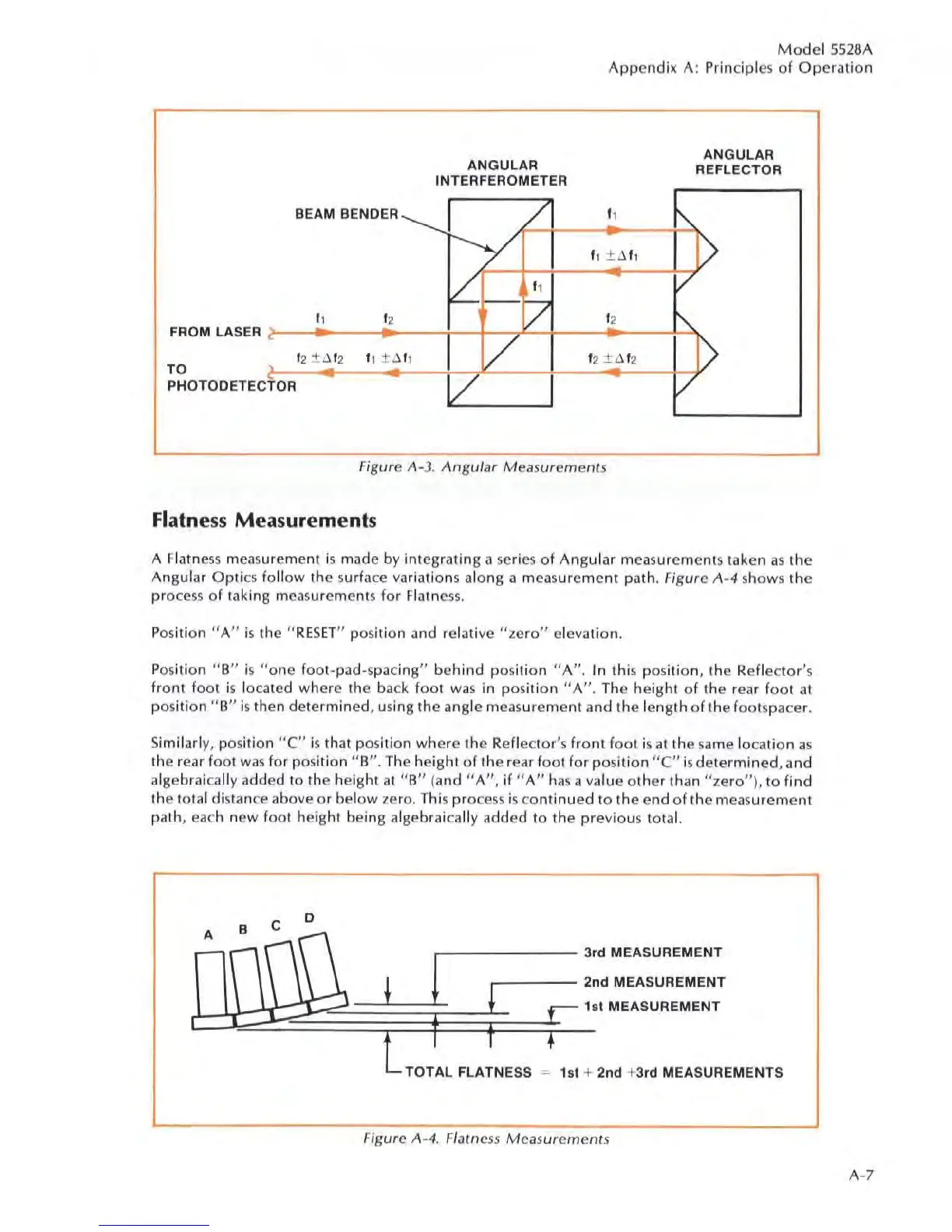

Flatness Measurements

A Flatness

mea

surement is made

by

integrating a

se

ries

of

Angular measurements taken

as

the

Angular

Optics

follow

the surface

va

riations along a measurement path. Figure

A-4

shows

the

process of taking

mea

surements for Flatne

ss.

Position

"A"

is the

"RES

ET

" position and relative

"ze

r

o"

elevation.

Po

sition

"B"

is " one foot-pad

-s

pacing"

behind

po

s

ition

"A".

In

Ihi

s position, the Reflector

's

front

foot is located where the back foot

was

in positi

on

"A"

. The height

of

the rear

foot

at

position " B" is then determined, using

the

angle

meas

ur

ement and the length

of

the foolspacer.

Si

milarly, position "e" is that position

where

the Reflec

tor

's

front

f

oo

t is at the

sa

me location

as

the rear

fOO

l

was

for position

"B".

The height

of

the rear

fOOl

for

position

tiC"

isdetermined

, and

algebraically added to the height

at

li

B"

(and " A

",

if

"A"

ha

s a

va

lue

other

than

"ze

r

o"

),

to

find

the

tol

al

distan

ce

above

or

below zero. This process is co

ntinued

to

the

end

of

the meas

urement

path, each new foot height being algebraically added

to

the previous total.

A

\I'~

B C

D

~

!

r

3,

d MEASUREMENT

2

nd

MEASUREMENT

t MEASUREMENT

1s

= 1st + 2nd +3rd MEASUREMENTS

Figure

A-4

. Flatness Measurements

A-7

Loading...

Loading...