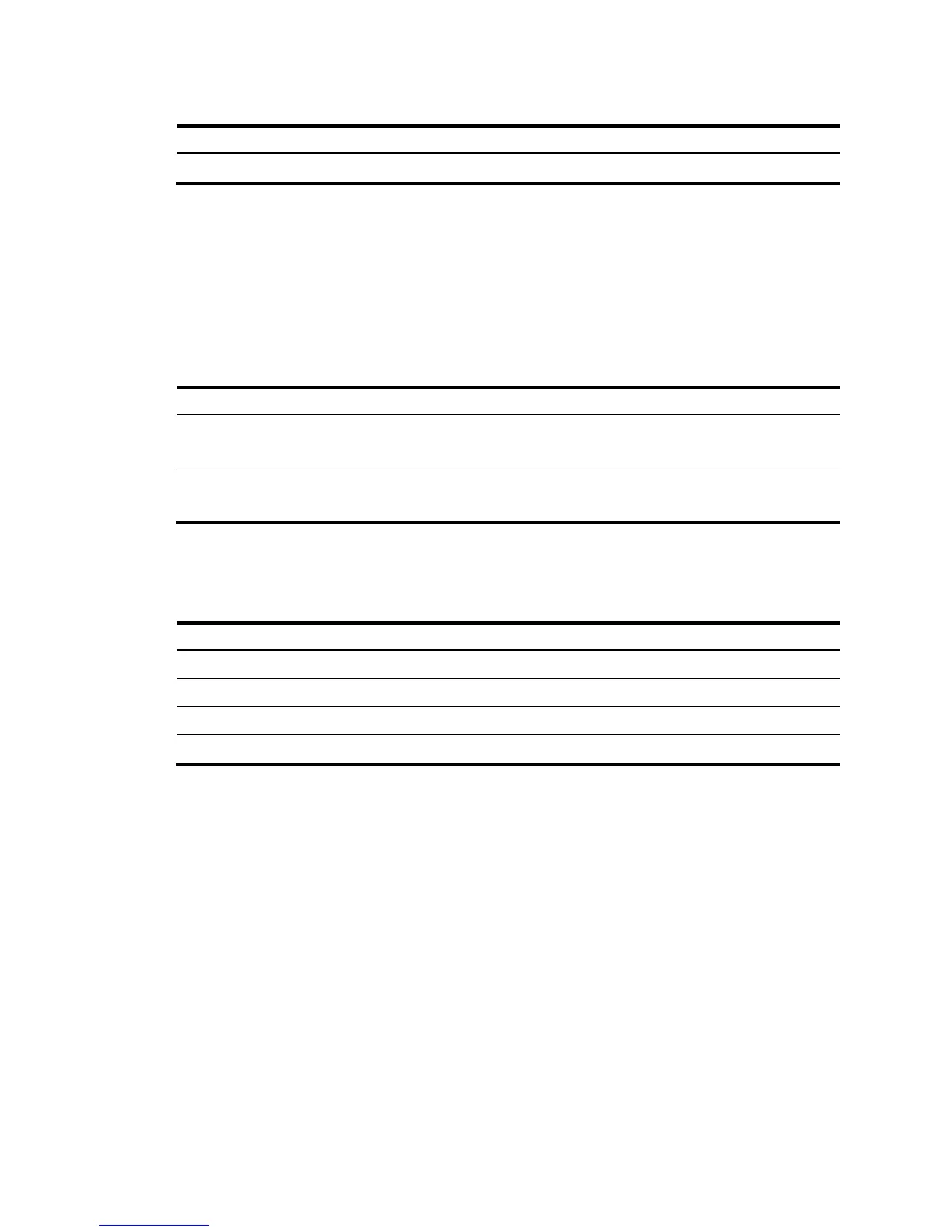

Table 1 Temperature/humidity requirements in the equipment room

0°C to 45°C (32°F to 113°F) 5% to 95%, noncondensing

Cleanness

Dust buildup on the chassis can result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure. To ensure correct operation, the equipment

room must meet the dust concentration requirements listed in Table 2.

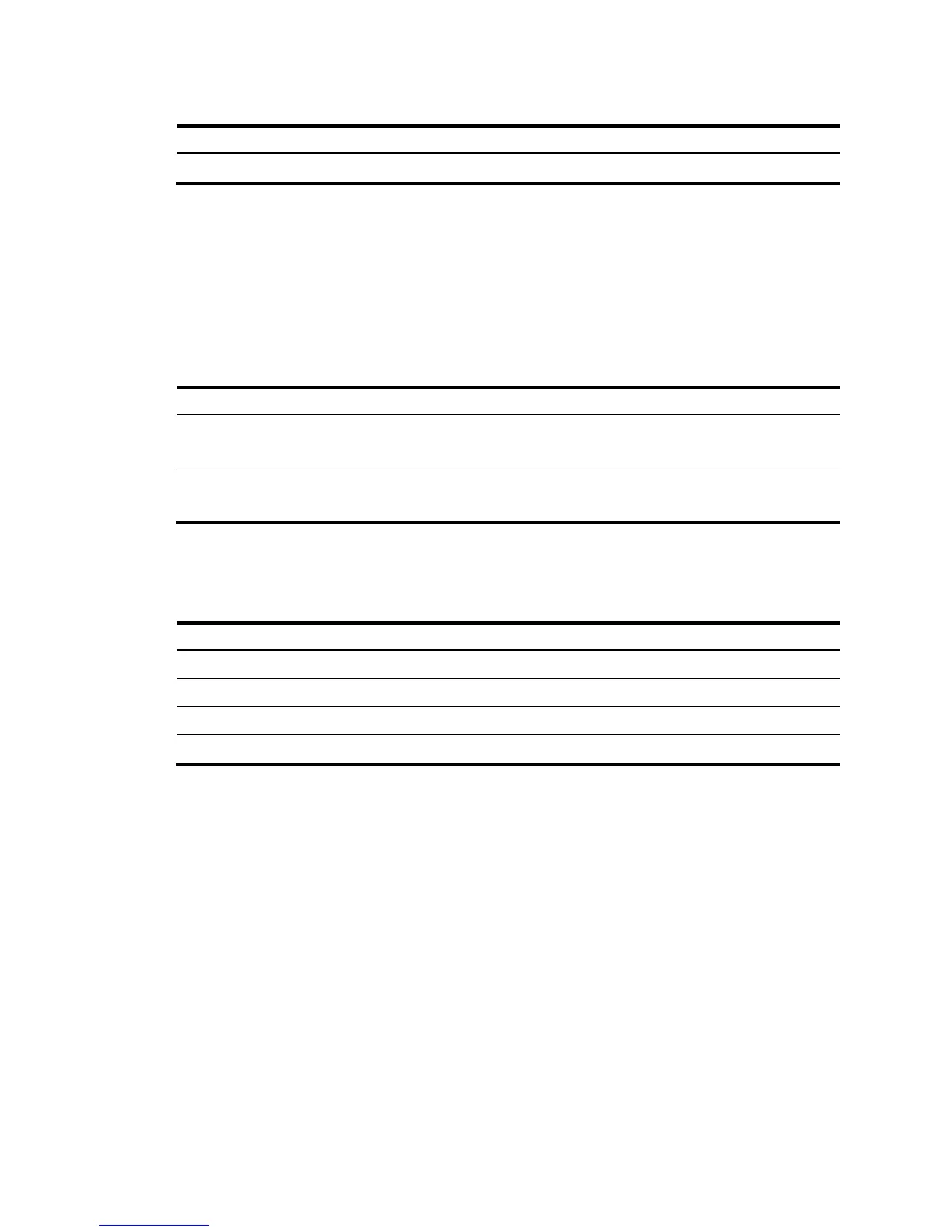

Table 2 Dust concentration limit in the equipment room

Concentration limit (particles/m

Dust particles

≤ 3 x 10

4

(No visible dust on desk in three days)

NOTE:

Dust particle diameter ≥ 5 µm

To eliminate corrosion and premature aging of components, the equipment room must also meet limits on

salts, acids, and sulfides, as shown in Table 3.

Table 3 Harmful gas limits in an equipment room

SO

2

0.2

H

2

S 0.006

NH

3

0.05

Cl

2

0.01

Cooling

The device uses left to right airflow for heat dissipation. Plan the installation site for adequate ventilation.

HP recommends that you leave a minimum of 10 cm (3.94 in) of clearance around the air vents.

Make sure the rack is well ventilated.

3

Loading...

Loading...