LP-551 Rev. 3.9.16

16

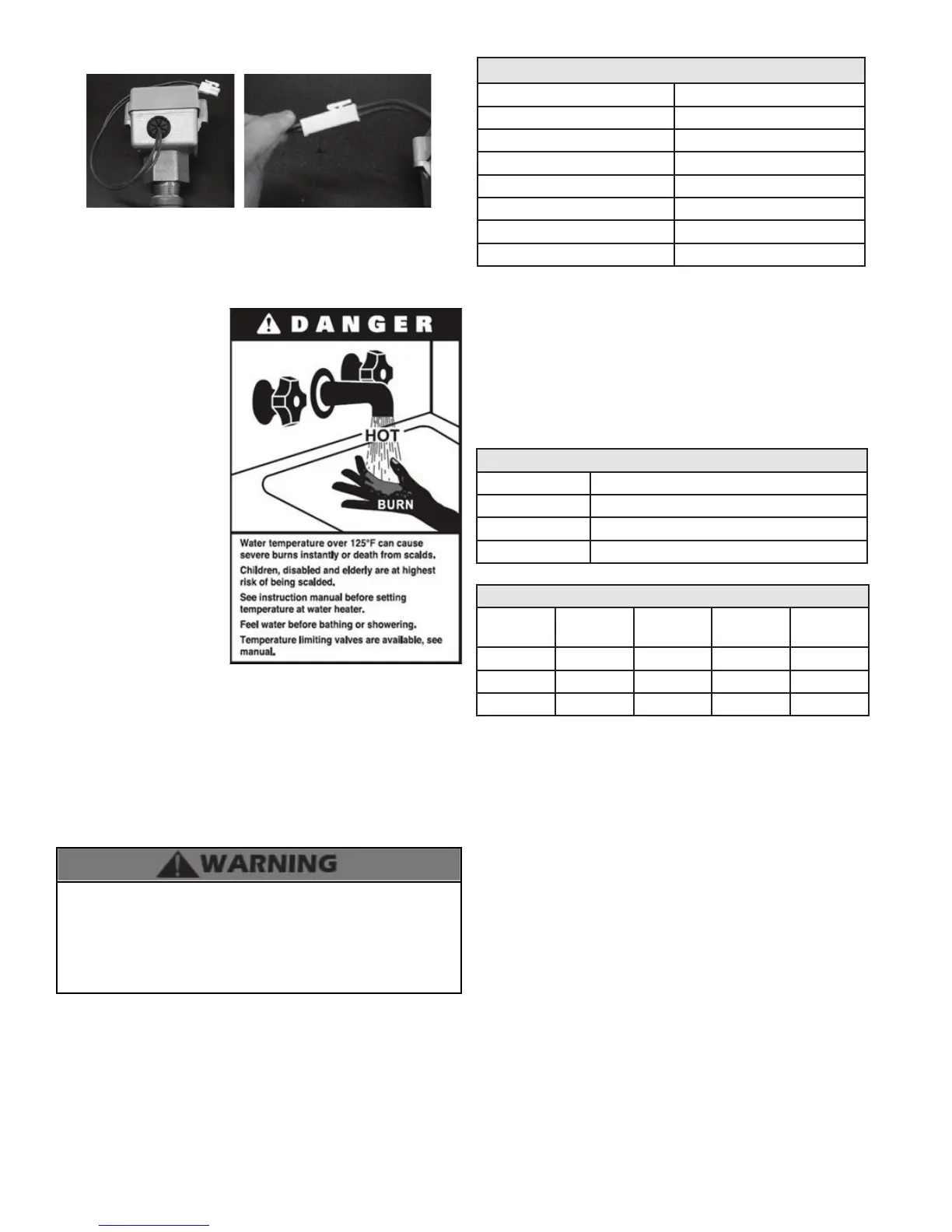

G. Scalding

This boiler can deliver

scalding water at any

faucet in the system.

Be careful whenever

using hot water to

avoid scalding injury.

Certain appliances

such as dishwashers

and automatic clothes

washers may require

increased water

temperatures. By

setting the thermostat

on this boiler to obtain

the increased water

temperature required

by these appliances you

may create the potential

for scald injury.

To protect against injury, install a mixing valve in the

water system. This valve will reduce point of use discharge

temperatures by mixing cold and hot water in branch supply

lines. Such valves are available from your local plumbing

supplier.

Table 5 details the relationship of water temperature and

time with regard to scald injury and may be used as a guide in

determining the safest water temperature for your applications.

The risk of scalding increases when raising tank temperature.

Use a water tempering or mixing valve when raising tank

temperature to lessen the chance of scalds. Consult codes for

conformance. Failure to install a temperature limiting or mixing

valve and follow these instructions could result in property

damage, severe personal injury, or death due to scalds.

Approximate Time / Temperature Relationships in Scalds

120

o

F More than 5 minutes

125

o

F 1 1/2 to 2 minutes

130

o

F About 30 seconds

135

o

F About 10 seconds

140

o

F Less than 5 seconds

145

o

F Less than 3 seconds

150

o

F About 1 1/2 seconds

155

o

F About 1 second

Table 5 - Approximate Time / Temperature Relationships in Scalds

H. High Velocity Circulator Pump

7. Connect red wire from ow switch to boiler wire harness.

8. When installation is complete, power up the boiler and

program set point. *Please note that these illustrations are

meant only to demonstrate installation. The installer is

responsible for all equipment and detailing required by local

codes.

Minimum Boiler Flow Rates

VWH Model Minimum Flow (GPM)

220 14.6

299 / 301 20

399 26

Table 6 - Minimum Flow Rates

Every VWH system requires special attention to pump size in

order to overcome pressure drop through the boiler and its

related piping. All circulators installed on the VWH system

must be designed for a potable water system.

In addition, the heat exchanger has a minimum total water

volume that must be taken into account when sizing the

circulator. Minimum ow rates are listed in the table below.

VWH Circulators and Flanges

VWH

Model

Circulator

Circulator

Part #

Flange Size

Flange

Part #

220 0013-SF3 7450P-241 1” NPT 7450P-242

299 / 301 2400-20S 7250P-605 1 1/4” NPT 7250P-603

399 2400-50S 7250P-606 1 1/2” NPT 7250P-604

Table 7 - VWH Circulators and Flanges

VWH Circulator Kits

• 220 Model - Part # 7450P-248

• 299 / 301 Models - Part # 7450P-249

• 399 Model - Part # 7450P-250

Loading...

Loading...