LP-428 Rev. 6.6.16

63

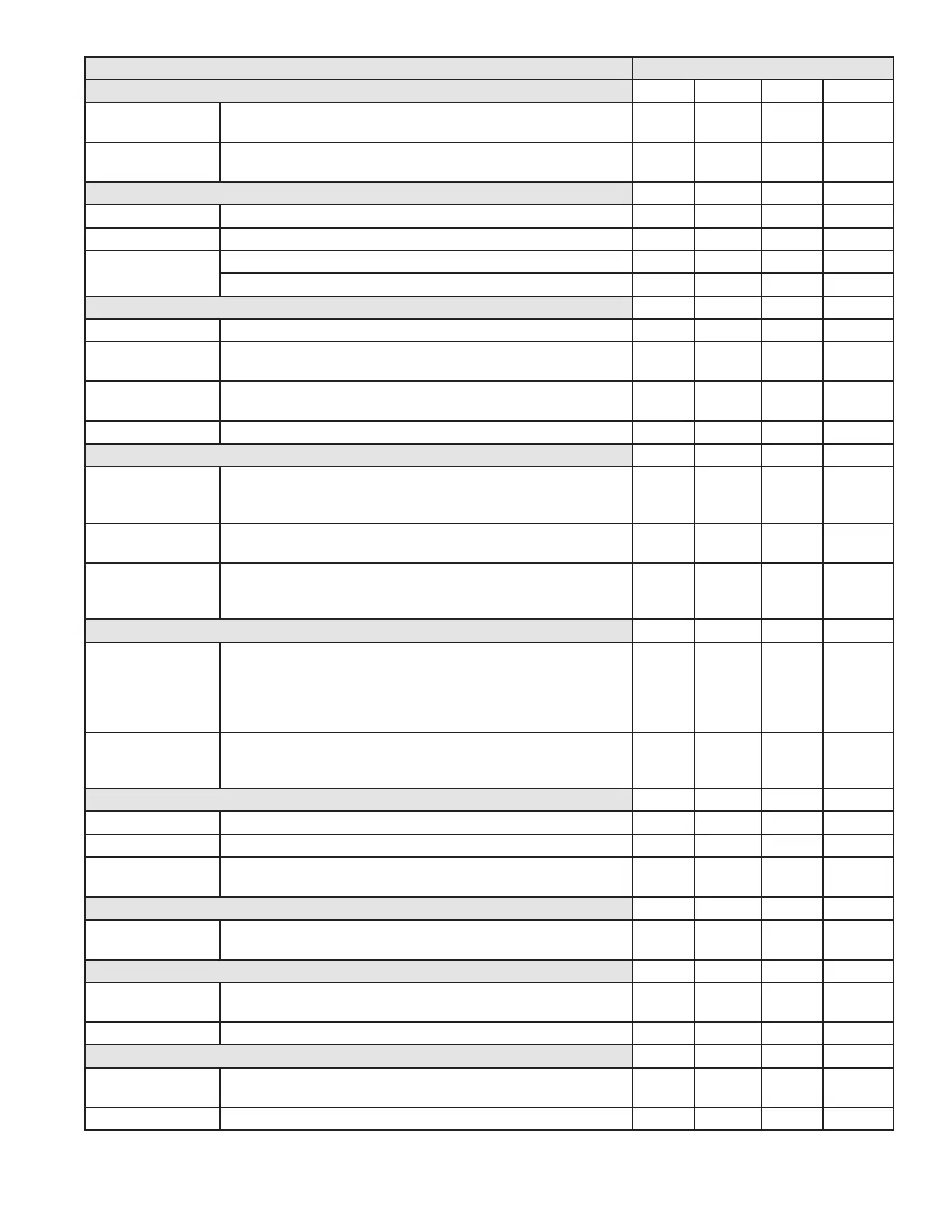

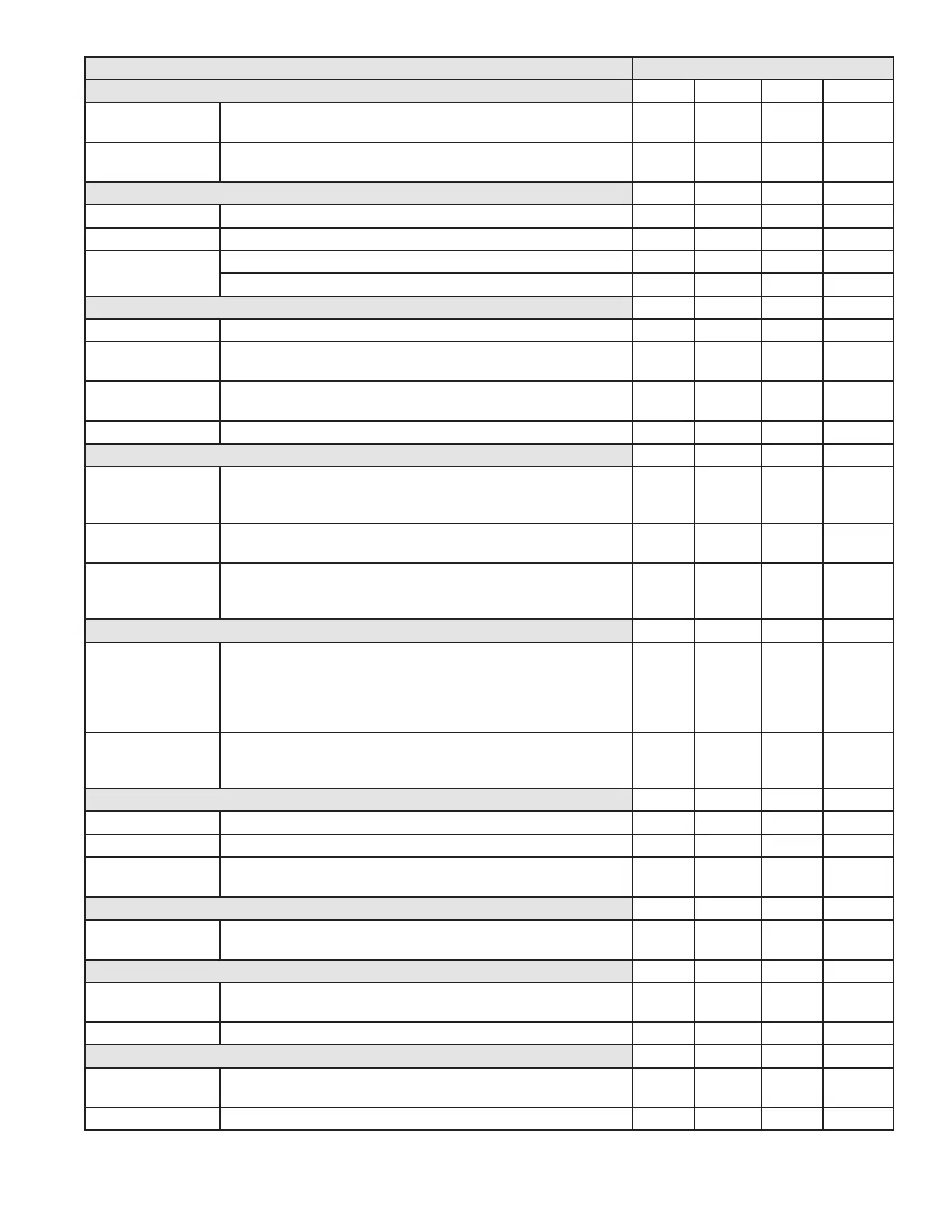

Inspection Activities Date Last Completed

Piping 1st Year 2nd Year 3rd Year 4th Year*

Near boiler piping

Check boiler and system piping for any sign of leakage; make sure

pipes are properly supported.

Vent

Check condition of all vent pipes and joints. Ensure the vent piping

terminations are free of obstructions and blockages.

System 1st Year 2nd Year 3rd Year 4th Year*

Visual Do a full visual inspection of all system components.

Functional Test all functions of the system (Heat, Safeties).

Temperatures

Verify safe settings on boiler or anti-scald valve.

Verify programmed temperature settings.

Electrical

Connections Check wire connections. Make sure connections are tight.

Smoke and CO

Detector

Verify devices are installed and working properly. Change batteries if

necessary.

Circuit Breakers Check to see that the circuit breaker is clearly labeled. Exercise circuit

breaker.

Switch and Plug Verify ON/OFF switch and convenience plug are both functional.

Chamber / Burner 1st Year 2nd Year 3rd Year 4th Year*

Combustion

Chamber

Check burner tube and combustion chamber coils. Clean according

to maintenance section of manual. Vacuum combustion chamber.

Replace any gaskets that show signs of damage.

Spark Electrode Clean. Set gap at 1/4” Clean probe with plumbers cloth to remove

oxides.

Combination Ignitor

and Flame Probe

Check ionization in uA (d7 in Status Menu in Start-Up Procedures).

Record high re and low re. Clean probe with plumbers cloth to

remove oxides.

Condensate 1st Year 2nd Year 3rd Year 4th Year*

Neutralizer Clean out condensate neutralizer. Use wet/dry vacuum. Check for all

potential obstruction issues. Replenish marble chips or lime crystals if

needed (no smaller than ¾”). Rell system with water. WARNING: You

must verify ow of condensate and make sure the cap is connected

properly before leaving boiler unattended.

Condensate System Check entire condensate system to make sure there are no obstructions

in ow. Make sure the condensate pump is working properly, verify all

connections.

Gas 1st Year 2nd Year 3rd Year 4th Year*

Pressure Measure incoming gas pressure (3.5 to 14” WC).

Pressure Drop Measure drop in pressure on light o (no more than 1” WC).

Check Gas Pipe for

Leaks

Check gas piping. Test for leaks and signs of aging. Make sure all pipes

are properly supported.

Combustion 1st Year 2nd Year 3rd Year 4th Year*

CO / CO2 Levels Check CO and CO2 levels in exhaust. See Start-Up Procedures for

ranges. Record at high and low re.

Safeties 1st Year 2nd Year 3rd Year 4th Year*

ECO (Energy Cut

Out)

Check continuity on ue and water ECO. Replace if corroded.

Sensors Check wiring. Verify through ohms reading.

Final Inspection 1st Year 2nd Year 3rd Year 4th Year*

Check List Verify that you have completed entire check list. WARNING: FAILURE

TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH.

Homeowner Review what you have done with the homeowner.

Table 27 - *Continue annual maintenance beyond the 4th year as required.

Loading...

Loading...