21 22

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I RISER SEAL REPLACEMENT

RISER SEAL REPLACEMENT I TABLE OF CONTENTS

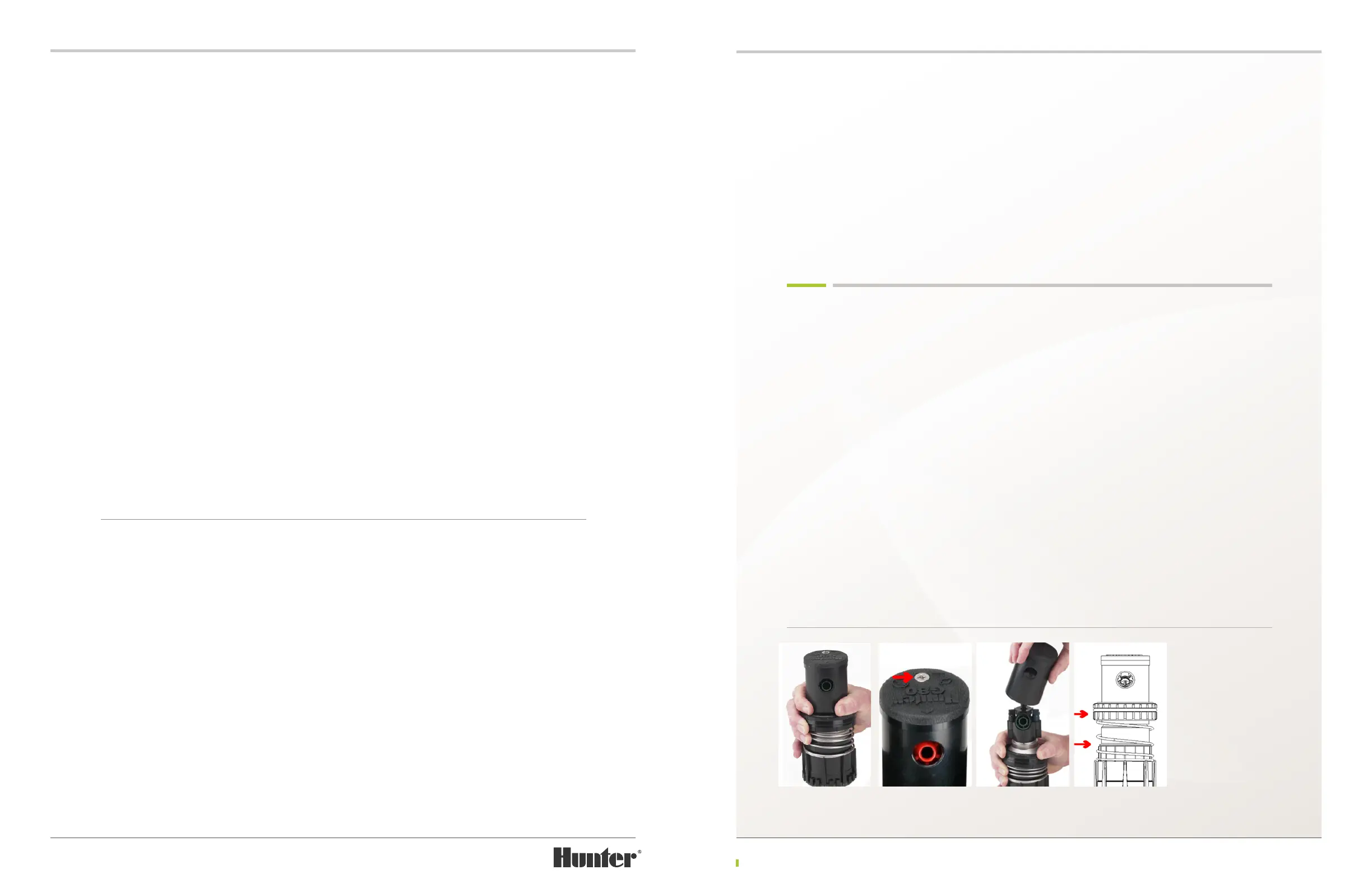

Slide the new face-seal down and onto the riser.

Make sure that it is pressed all the way until it

is seated rmly against the ledge at the base

of the stainless-steel portion of the riser. Install

the retraction spring and seal-block assembly

onto the G80 riser. Press down on the seal-block

to compress the retraction spring and hold

rmly in this position.

To install the nozzle housing’s shroud/logo-cap

assembly, position it over the nozzle housing.

The single opening for the Primary long-range

nozzle in the shroud must be positioned directly

over the long-range (largest) nozzle. Press into

position and conrm all three nozzle openings

are lined up with the nozzles inside. Install the

stainless steel screw into the rubberized logo

cap by turning it clockwise until hand tight.

RISER SEAL REPLACEMENT G90 & G95 RISERS

The G90 and G95 riser seal assembly and the

compressed retraction spring are retained on

the riser with the retainer cap (plastic plate) at

the top of the riser assembly. It is necessary to

remove the retainer cap in order to replace the

riser seal components. To remove the retainer

cap, fully compress the riser spring by grabbing

the riser seal assembly (FIGURE 51), pressing

downward and then holding riser rmly to

prevent the spring from moving upwards.

Caution! The riser assembly is under spring tension. Eye protection should be worn and safe-

handling procedures followed when servicing this product.

Hold the riser seal assembly down with one

hand. Locate the two screws that hold the

retainer cap to the riser assembly (FIGURE

52). Use a Phillips screwdriver to engage each

retaining screw and turn counter-clockwise

to remove. Prior to removing the G90 or G95

retainer cap, note its orientation as it relates

to the nozzles below. This will help with the

assembly process later. Remove the retainer

cap and set aside.

While still holding the compressed riser seal

assembly and retraction spring with one hand,

use the other hand to grasp the bottom of the

riser assembly. Slowly release the compression

of the retraction spring until it is fully extended

and no pressure is felt. Note the orientation

of the riser components to help with assembly

later (FIGURE 53).

The riser seal on G80 risers include two primary components - the seal block assembly and the

face-seal. The seal block assembly sits on top of the retraction spring and has two sealing surfaces.

First, the seal block has an O-Ring around the outside. If the O-Ring is damaged, deteriorated or

missing, the riser will leak water while the sprinkler is operating. The second sealing surface on

the seal-block assembly is on the underside. The angled surface on the underside of the seal-block

assembly is the interface for the face-seal. If this angled interface surface is cut or otherwise

damaged, the riser can leak water during sprinkler operation.

The face-seal is the second primary component to the G80’s riser seal design. The face-seal is the

white plastic angled ring that is position at the base of the stainless-steel portion of the G80’s

riser. If the face-seal is damaged, deteriorated or missing, the riser will leak during sprinkler

operation.

If the riser is leaking during sprinkler operation, the O-Ring, the interface, and the face-seal must

be inspected in order to determine the cause of the leakage. If the O-Ring is damaged, it can

easily be replaced by removing the damaged O-Ring from the seal-block and replacing it with a

new

one. Use care to ensure that the O-Ring is not cut or twisted during the installation process. If the

interface is damaged, the entire seal-block must be replaced. Also, if the interface is damaged it

is highly likely that the face-seal is damaged as well and needs replacement.

To replace the face-seal, slide it upwards and o the riser assembly. Replacement face-seals must

t very snug to the stainless-steel on the riser. As a result, there may be considerable resistance

when attempting to install the new face-seal. To make installation easier, the face-seal’s diameter

can be expanded by placing it in the sun for several minutes. Or, if the repair is being done in the

shop, placing the face-seal in warm water for several minutes will cause expansion as well.

FIGURE 47 FIGURE 48 FIGURE 49 FIGURE 50

Loading...

Loading...