37 38

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I INLET VALVE SERVICING

INLET VALVE REMOVAL I TABLE OF CONTENTS

INLET VALVE SERVICING ALL MODELS

Inlet Valves (also commonly known as foot

valves) do not have serviceable internal parts

and the valves are welded together as an

assembly. As a result, inlet valves cannot be

taken apart. Any disassembly of an inlet valve

will lead to a valve that is no longer usable.

Contamination within the inlet valve can cause

the valve to leak. To remove contamination

within the inlet valve, follow the procedures

below:

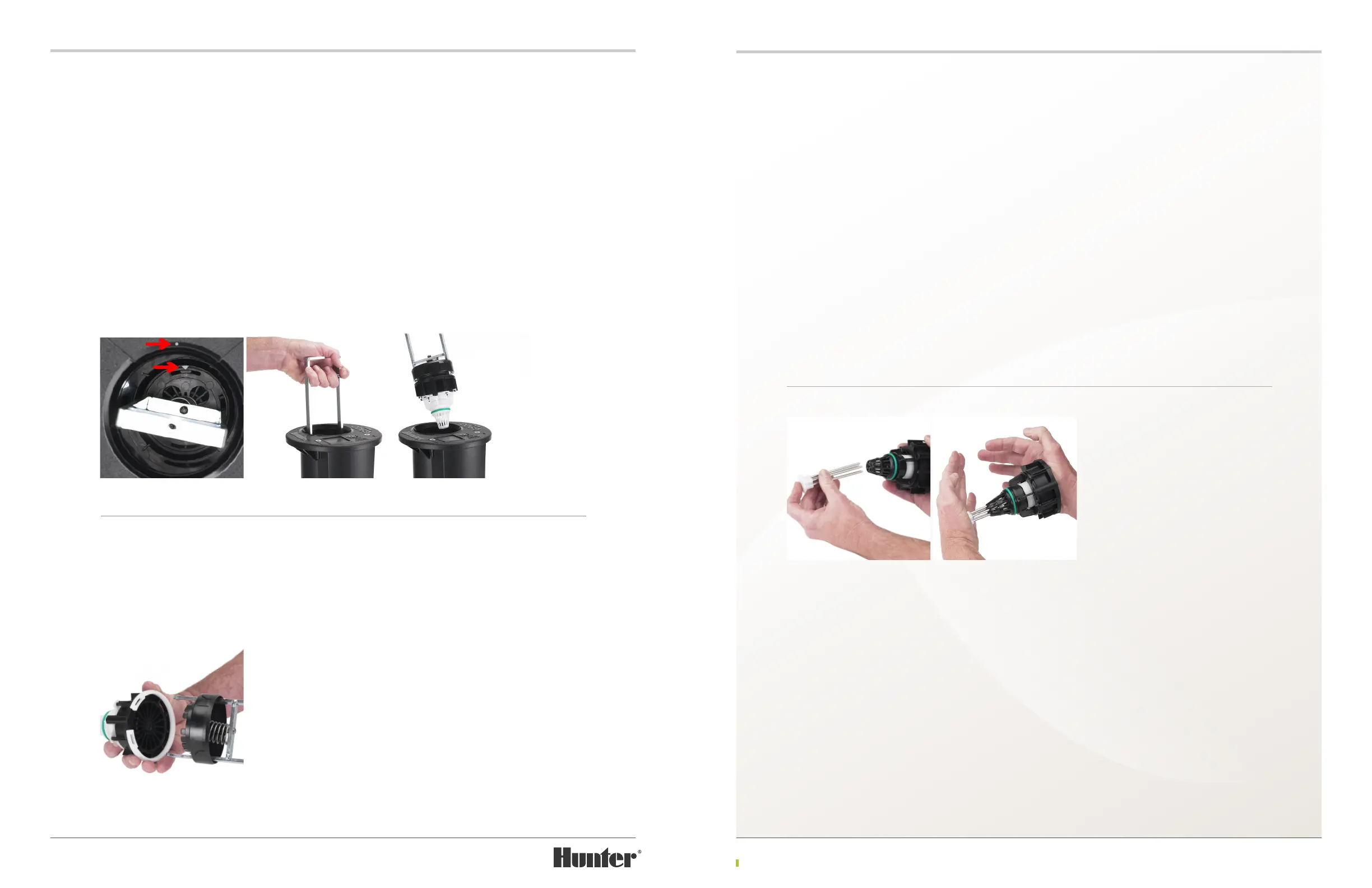

Fill a bucket with clean water. Using the TTS

Valve Flushing Tool, insert the stainless steel

metal pins on the tool into the holes at the

bottom of the inlet valve’s screen (FIGURE

98). While holding the TTS Valve Flushing Tool

in the palm of one hand and the top of the

inlet valve with the other hand, lower the inlet

valve into the bucket of water. To clean & ush

contamination from the valve, rmly push the

tool into the valve (FIGURE 99). Resistance

will be felt as the valve’s internal spring is

compressed. Cycle the valve open & closed

with the tool multiple times while holding it

submerged in the bucket of water. Remove

the valve from the water and inspect for any

remaining contamination.

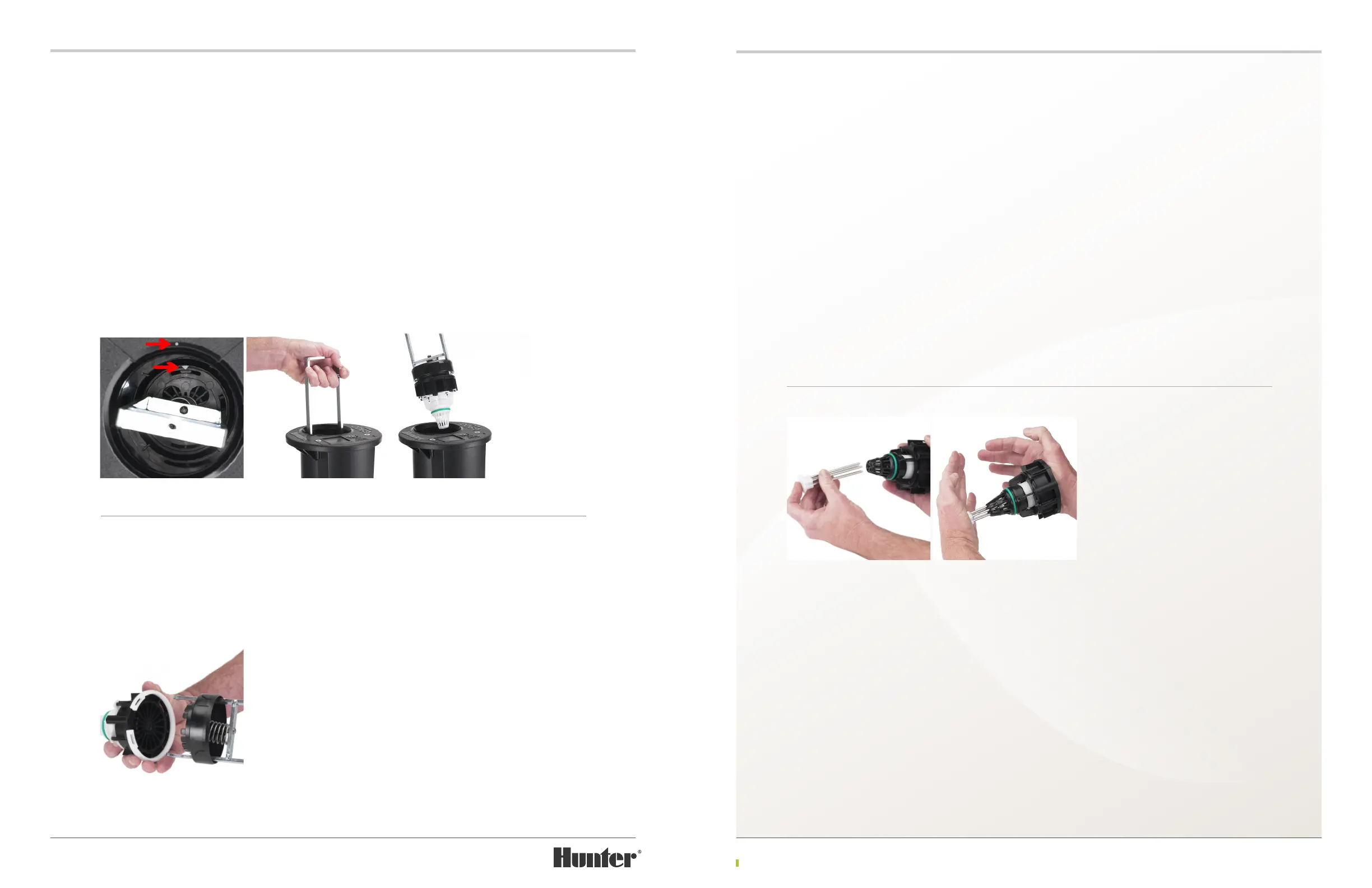

To remove the inlet valve, it is necessary to align the pointer arrow on the G900 Valve Tool with

the alignment dot on the rotor’s ange. The alignment dot is centered on the ange compartment

lid adjacent to (next to) the body cavity opening. A second alignment dot is located below the lid

in case the ange compartment lid has been removed. Align the pointer arrow on the tool with the

alignment dot (FIGURE 94) and lower the tool into the rotor’s body (FIGURE 95).

As the G900 Valve Tool is lowered into the rotor’s body, recessed areas on the black plastic part

on the tool will engage vertical rails inside the body wall. The tool must engage these rails or the

tool will not align with the inlet valve below. Continue pressing downward compressing the spring

on the G900 Valve Tool. While holding the tool down with the spring compressed, turn the tool’s

handle clockwise until it stops. Next, release the spring’s compression by liing the handle slightly

on the G900 Valve Tool. This action hooks and locks the inlet valve to the tool. Finally, pull upward

on the tool’s handle to remove the tool and inlet valve from the rotor’s body (FIGURE 96).

FIGURE 94 FIGURE 95 FIGURE 96

Important – Take note of how the G900 Valve Tool nests with the attached inlet valve. This will

help later when attaching the inlet valve to the tool prior to inlet valve installation.

To disengage the inlet valve from the G900 Valve Tool, hold the inlet valve with one hand and the

tool with the other hand. Next, push the tool’s handle toward the inlet valve to compress the tool’s

spring. With the spring held compressed, rotate the tool’s handle counter-clockwise to release the

tool’s hooks from the inlet valve.

FIGURE 97

FIGURE 98 FIGURE 99

rotate the tool’s handle counter-clockwise to re-

lease the tool’s hooks from the inlet valve.

Loading...

Loading...