55 56

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I PRESSURE REGULATOR ADJUSTMENT

ATTACHING SELECTOR CAP TO SOLENOID I TABLE OF CONTENTS

ATTACHING SELECTOR CAP TO THE SOLENOID

The Selector Cap turns the Solenoid when the user changes the ON-AUTO-OFF settings. Under

normal operating conditions, the Selector Cap should not need replacement. The Selector Cap can

become damaged if the incorrect tool is used to make ON-AUTO-OFF selection adjustments.

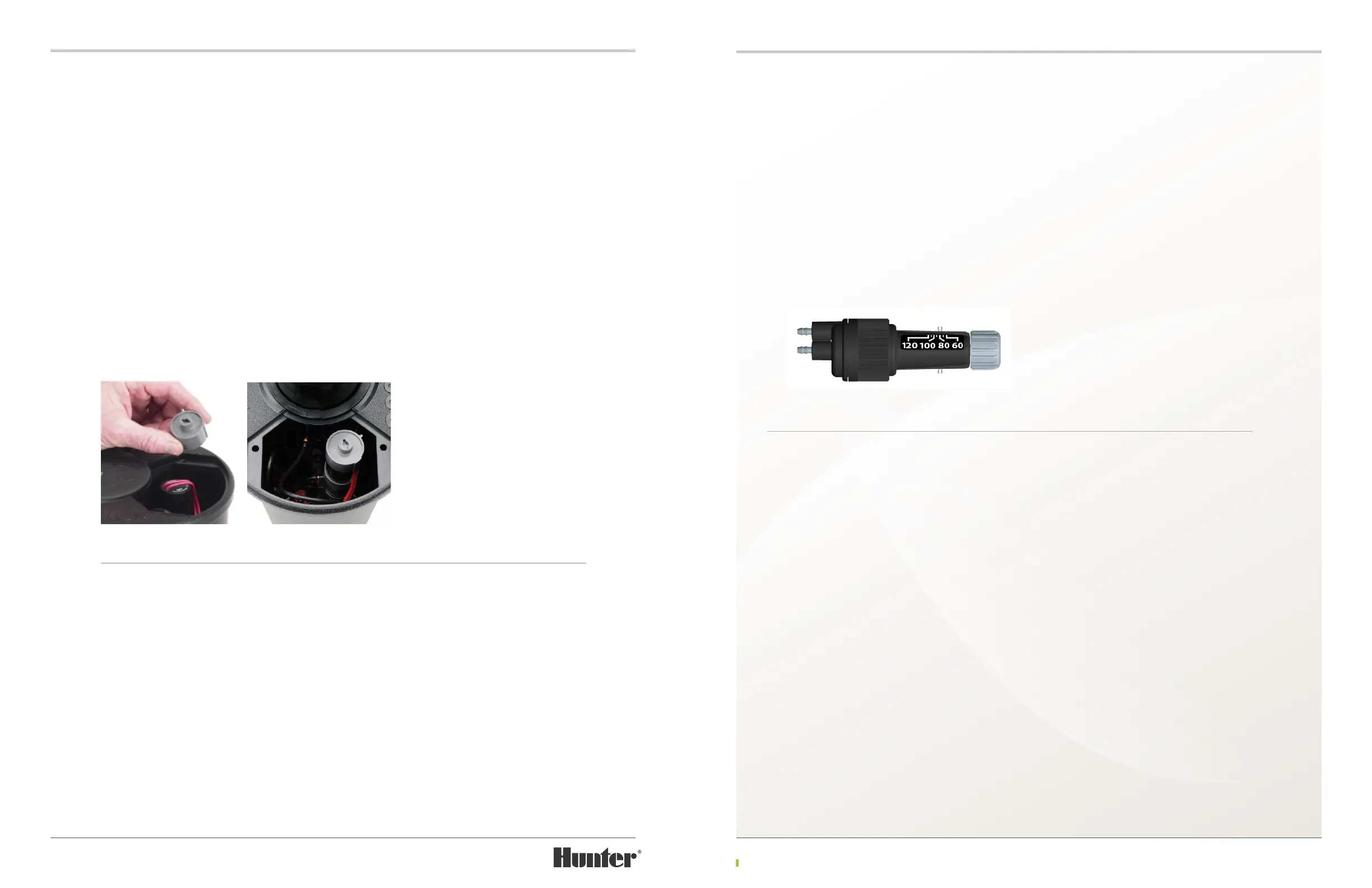

With the Solenoid and Pilot Valve assembly installed in the ange compartment and the Solenoid

set to the Auto position (see instructions above), proceed as follows. The at side of the Solenoid

should be facing away from the rotor’s riser assembly pointing towards the outside of the ange

compartment (FIGURE 142).

Starting from where the Solenoid’s lead wires come out of the top of the Solenoid, place the lead

wires side-by-side over the top and down the at side of the Solenoid (FIGURE 143). While holding

the Solenoid’s lead wires in this position, place the Selector Cap on top of the Solenoid. The

Selector Cap must be oriented such that the Solenoid’s lead wires t into the recessed channel

on the inside wall of the Selector Cap. Press the Selector Cap down and onto the Solenoid

(FIGURE 144).

PRESSURE REGULATOR PURPOSE, SETTINGS AND ADJUSTMENT PROCEDURES

Regulation settings are preset at the factory. If the installed rotor has been preset to the specied

regulation setting for your irrigation system, further Pressure Regulator adjustments are not

normally necessary. If a replacement TTS rotor is being installed, it may be necessary to adjust the

regulation setting.

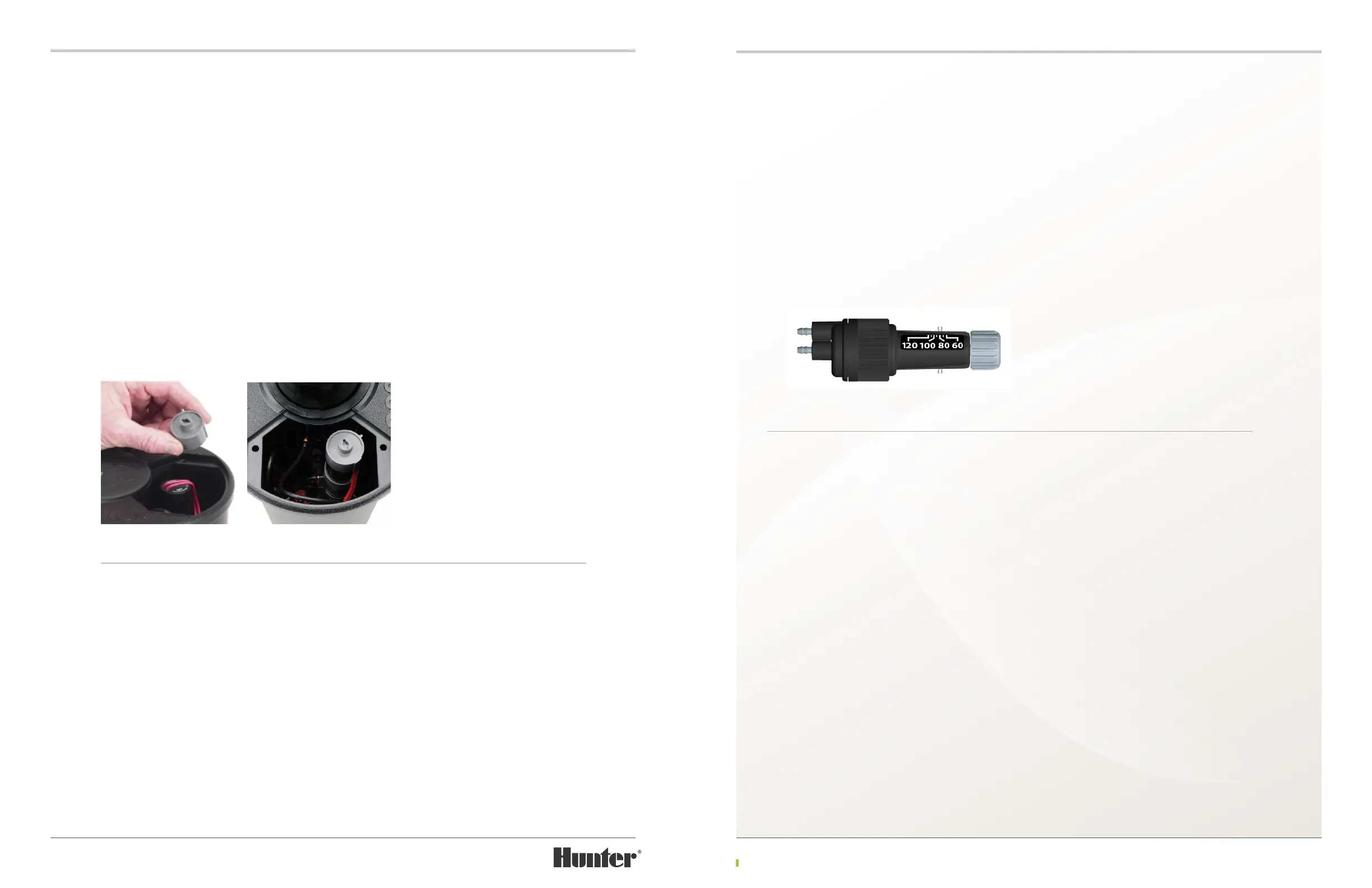

Pressure Regulator Purpose – The purpose of the Pressure Regulator (FIGURE 145) is to ensure

that a specically set pressure is supplied to the rotor’s nozzles. Since the amount of ow through

the nozzles is aected by pressure, supplying a consistent pressure to every rotor in the irrigation

system is benecial. This will help to ensure that all rotors with the same size nozzles will have the

same application rate (also known as the precipitation rate).

Pressure regulation also prevents too much

pressure from reaching the nozzles. Rotors

that are closer to the pump station or rotors

that are at a lower elevation will have relatively

higher pressures than rotors that are at the

far reaches of the irrigation system’s piping or

those at higher elevations. Abnormally high

pressures at the nozzles can cause misting of

the water droplets. Water that is misting will

be easily carried away from its intended target

by the wind.

Pressure Regulator Settings – All electric

valve-in-head TTS rotors have adjustable Pressure

Regulators. One of the many benecial features

of the TTS rotor is the fact that the Pressure

Regulation is conveniently adjustable yet hidden

within the ange compartment. This prevents

untrained personnel or golfers from shutting

down a rotor during operation and inadvertently

changing its regulation setting.

PRESSURE REGULATOR ADJUSTMENT

The variable setting Pressure Regulator has

been calibrated from the factory and set to a

specic regulation setting. This setting will not

normally need to be changed. The variable

Pressure Regulator has a pointer and a pressure

indicating scale on the side of its body with a

range of 60 PSI to 120 PSI. If pressure setting

adjustments are required, it is important to note

the following:

The calibrated pressure setting from the

factory is very accurate. However, the pressure

indicating scale is only a pressure setting

reference when making adjustments in the

eld. For more precise pressure regulation

adjustment in the eld, use a pitot gauge at the

nozzle to the check pressure.

FIGURE 143 FIGURE 144

FIGURE 145

Loading...

Loading...